Use of Permanent Magnets in AdBlue Systems

AdBlue is a diesel exhaust fluid (DEF) used in selective catalytic reduction (SCR) systems to reduce harmful emissions from diesel engines. Permanent magnets play a critical role in enhancing the performance and reliability of AdBlue systems. This article explores how permanent magnets are used in AdBlue systems and their benefits.

What is AdBlue?

AdBlue is a high-purity urea solution that is injected into the exhaust stream of diesel engines to break down harmful nitrogen oxides (NOx) into harmless nitrogen and water. This process occurs in the SCR catalyst, a crucial component of modern diesel exhaust after-treatment systems aimed at meeting stringent emission regulations.

Applications of Permanent Magnets in AdBlue Systems

- Flow Sensors

Permanent magnets are used in flow sensors to measure the amount of AdBlue being injected into the exhaust stream. These sensors ensure the correct dosage is delivered, optimizing the SCR process for maximum emission reduction.

- Level Sensors

AdBlue level sensors use permanent magnets to detect the fluid level in the AdBlue tank. The sensor typically consists of a float with an embedded magnet that moves with the fluid level, and a reed switch or Hall effect sensor outside the tank that detects the position of the magnet.

- Pump Systems

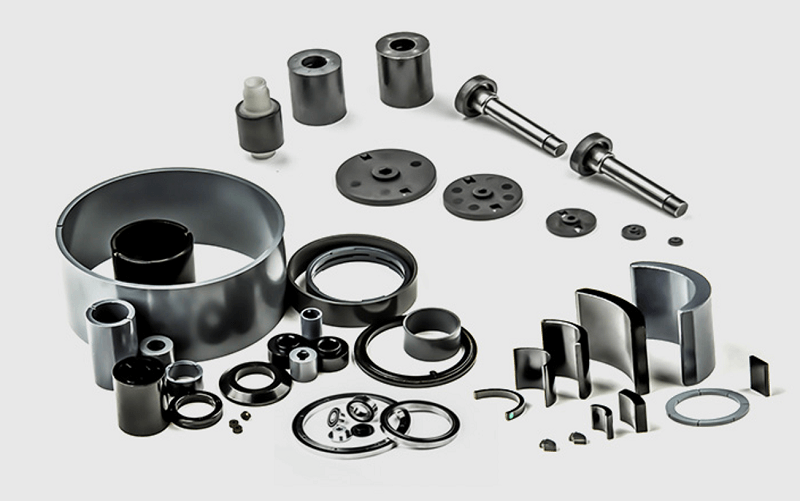

Permanent magnets are integral components in the electric pumps used to transfer AdBlue from the tank to the injector. These magnets help ensure efficient and reliable operation of the pump by providing precise control over the pump’s motor.

- Injector Valves

Magnets are used in the injector valves that control the injection of AdBlue into the exhaust stream. Solenoid valves with embedded permanent magnets allow for precise opening and closing, ensuring accurate dosing of the fluid.

- Heating Elements

In colder climates, AdBlue can freeze at temperatures below -11°C (12°F). Permanent magnets are used in the heating elements that prevent the fluid from freezing, ensuring continuous operation of the SCR system even in low temperatures.

Benefits of Using Permanent Magnets in AdBlue Systems

- Precision and Reliability

Permanent magnets provide high precision and reliability in sensors and actuators. This ensures accurate measurement and control of AdBlue flow, level, and injection, leading to optimal SCR performance and reduced emissions.

- Durability

Permanent magnets, especially those made from NdFeB, offer excellent durability and resistance to demagnetization. This ensures long-term performance and reliability of the AdBlue system components.

- Energy Efficiency

Magnets enable efficient operation of electric pumps and valves, reducing the overall energy consumption of the AdBlue system. This contributes to the overall efficiency of the vehicle’s emissions control system.

- Compact Design

The strong magnetic properties of NdFeB and SmCo magnets allow for compact and lightweight sensor and actuator designs. This is particularly beneficial in automotive applications where space and weight are critical considerations.

Summary

Permanent magnets play a vital role in the effective functioning of AdBlue systems, ensuring precise measurement, control, and efficient operation of various components. By enhancing the performance and reliability of flow sensors, level sensors, pumps, injector valves, and heating elements, permanent magnets help modern diesel engines meet stringent emission standards and operate efficiently in diverse environmental conditions.

.

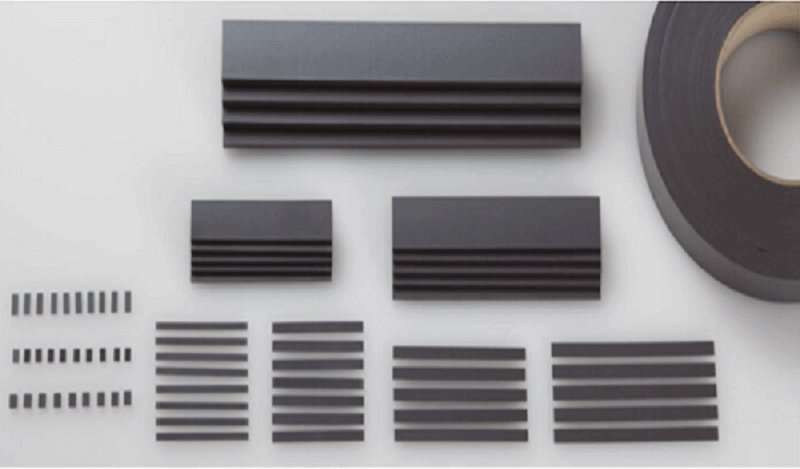

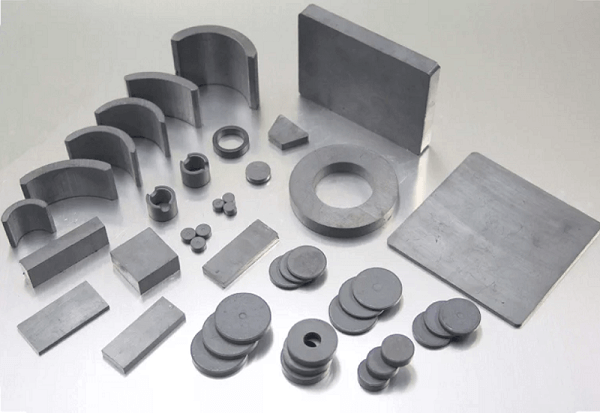

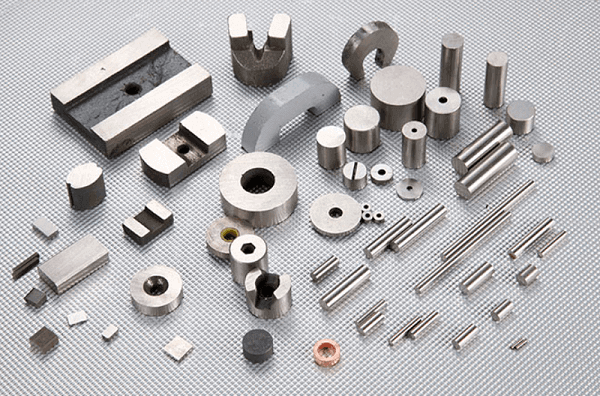

NBAEM, is the professional magnetic materials supplier from China. We have exported bespoke magnetic materials for more than ten years. We provide quality products and high-standard service. If you are looking for any magnetic materials sourcing or if you have any questions during importing the magnetic products from China, you can contact us directly.

Leave A Comment