Definition of Magnetic Hysteresis

Magnetic hysteresis is a property of ferromagnetic materials where the material’s magnetic response depends not only on the current magnetic field but also on its past exposure to magnetic fields. In simple terms, when you apply a magnetic field to materials like iron, they become magnetized. However, when the magnetic field changes or is removed, these materials don’t instantly lose their magnetization. Instead, they retain some magnetic memory, which causes a lag in their response.

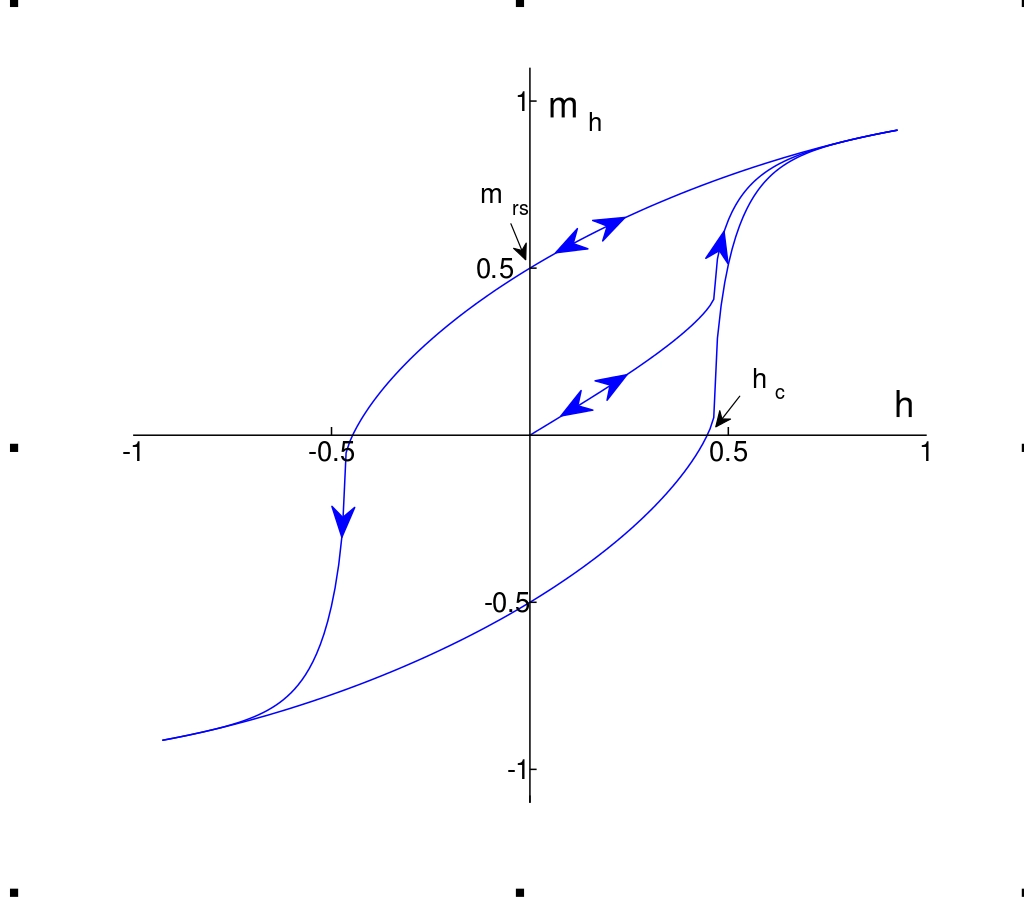

This lagging behavior is explained by the physics of magnetic domains—small regions inside the material where magnetic moments are aligned. When an external magnetic field is applied, these domains grow or shrink but do not immediately return to their original state when the field changes. This creates a looped pattern known as the magnetic hysteresis loop.

The hysteresis loop graphically represents how the magnetization (magnetic flux density) of a material changes in response to the applied magnetic field strength (magnetic field intensity). It reveals key characteristics such as coercivity (resistance to demagnetization) and retentivity (remaining magnetization), critical for understanding and designing magnetic devices.

How Magnetic Hysteresis Works

Magnetic hysteresis happens because of the way magnetic materials respond when you magnetize and then demagnetize them. When you apply a magnetic field, the material’s tiny magnetic regions, called domains, start to line up with that field. This alignment is what creates magnetization. But when you take away or reverse the magnetic field, these domains don’t go back to their original state immediately. This lag is what causes the hysteresis effect.

The magnetic hysteresis loop, or B-H curve, is a graph that shows how the material’s magnetic flux density (B) changes with the applied magnetic field strength (H). Important parts of this loop include:

- Coercivity: The reverse magnetic field needed to bring the magnetization back to zero. It shows how ‘stubborn’ the magnet is about holding its magnetism.

- Retentivity (or remanence): The amount of leftover magnetization when the external magnetic field is removed. This tells you how much magnetic memory the material retains.

- Saturation magnetization: The maximum magnetization a material can reach when all the domains are fully aligned.

Types of Magnetic Materials and Their Hysteresis Characteristics

Magnetic materials mainly fall into two categories: soft magnetic materials and hard magnetic materials. Each type shows different hysteresis behavior, which affects their practical use.

Soft Magnetic Materials

- Have narrow hysteresis loops

- Low coercivity (easy to magnetize and demagnetize)

- Low retentivity (they don’t hold magnetization well)

- Ideal for applications needing quick magnetic response and minimal energy loss

Common Examples:

- Silicon steel

- Ferrites

Hard Magnetic Materials

- Show wide hysteresis loops

- High coercivity (resists demagnetization)

- High retentivity (holds magnetization for a long time)

- Used where permanent magnetization is needed

Common Examples:

- Rare earth magnets (like neodymium and samarium-cobalt)

| Property | Soft Magnetic Materials | Hard Magnetic Materials |

|---|---|---|

| Coercivity | Low | High |

| Retentivity | Low | High |

| Hysteresis Loop | Narrow | Wide |

| Energy Loss (Hysteresis Loss) | Low | Higher |

| Application | Transformers, inductors | Permanent magnets, motors |

Understanding these differences helps select the right material based on efficiency, magnetic memory needs, and energy consumption—especially critical in the U.S. market for industries like power, electronics, and automotive.

For more on how magnetic materials work, check out this soft vs hard magnetic materials guide.

Significance of Magnetic Hysteresis in Magnetic Materials

Magnetic hysteresis plays a big role in how magnetic materials perform, especially when they’re used in everyday devices. One major issue is energy loss due to hysteresis, often called hysteresis loss. This loss happens because when a magnetic material like a transformer core or motor winding cycles through magnetization and demagnetization (AC applications), it wastes energy as heat. That reduces efficiency and can increase operating costs.

In transformers, inductors, and electric motors, hysteresis loss limits how well the device converts and transmits electrical energy. The more pronounced the hysteresis loop, the more energy gets lost. This is why choosing materials with low coercivity and narrow hysteresis loops is important for improving device efficiency.

Beyond power applications, magnetic hysteresis is critical for magnetic storage devices and sensors. Retentivity—the ability of a magnetic material to remember its magnetization—makes it possible to store the data in hard drives or keep sensors stable and reliable. Without controlled hysteresis properties, these devices wouldn’t work predictably or hold information well.

Understanding and managing magnetic hysteresis is key for designing better, energy-efficient magnetic components and reliable data technologies.

Practical Applications of Magnetic Hysteresis

Magnetic hysteresis plays a crucial role in many practical technologies, especially in electrical engineering. In transformers, motors, and generators, controlling hysteresis helps improve efficiency by reducing energy losses during magnetization cycles. This directly impacts the performance and longevity of these machines.

In data storage, magnetic hysteresis is the foundation of magnetic recording. Devices like hard drives rely on materials that retain magnetic states (retentivity) to store data reliably over time. The hysteresis properties ensure the data remains intact until intentionally changed.

Magnetic sensors and switches also depend on hysteresis. These devices use the magnetic memory effect to detect changes in magnetic fields or control circuits based on magnetic states. This makes them essential in automation and safety systems.

Finally, magnetic hysteresis helps in magnetic shielding and noise filtering. Materials with specific hysteresis characteristics can block or reduce unwanted magnetic interference, protecting sensitive electronics in medical devices, communication systems, and industrial equipment.

Measuring and Analyzing Magnetic Hysteresis

To understand and optimize magnetic hysteresis, we rely on precise instruments that measure the magnetic hysteresis loop, also called the B-H curve. The two most common tools are:

- Vibrating Sample Magnetometer (VSM): Measures magnetic properties by vibrating the sample in a magnetic field, detecting changes in magnetization.

- B-H Loop Tracer: Directly traces the hysteresis loop by measuring magnetic field strength (H) against magnetic flux density (B).

These tools help gather key parameters from the hysteresis loop:

| Parameter | What It Means | Why It Matters |

|---|---|---|

| Coercivity | The field needed to reduce magnetization to zero | Shows material’s resistance to demagnetization |

| Retentivity | Residual magnetization after removing the field | Indicates how well the material remembers magnetic state |

| Saturation Magnetization | Maximum magnetization a material can reach | Defines the material’s magnetic capacity |

| Hysteresis Loss | Area inside the loop representing energy lost | Critical for assessing efficiency, especially in AC use |

Manufacturers use these measurements in quality control to ensure materials meet specific standards for performance and efficiency. Consistency in magnetic properties means better reliability in transformers, motors, and storage devices used in the U.S. market.

Minimizing and Controlling Hysteresis Loss

Reducing hysteresis loss starts with choosing the right type of magnetic material. Soft magnetic materials like silicon steel or ferrites have low coercivity, meaning they magnetize and demagnetize easily with minimal energy loss. These are ideal for transformers and inductors where rapid magnetic changes happen. On the other hand, hard magnetic materials with high coercivity are great when you want a permanent magnet but generally have higher hysteresis loss.

To further control hysteresis loss, manufacturers often use treatments like:

- Annealing: Heating and slowly cooling materials relieves internal stresses, improving magnetic properties and lowering energy loss.

- Alloying: Adding elements like aluminum, nickel, or cobalt helps tailor magnetic behavior and reduce hysteresis.

Finally, smart design plays a big role. Engineers optimize magnetic device shapes, core sizes, and winding configurations to minimize unnecessary magnetic resistance and energy waste. Using laminated cores or powder cores also helps limit eddy currents, complementing hysteresis loss reduction efforts.

All these strategies combined make magnetic components more efficient and reliable, benefiting everything from transformers to electric motors used across the market.

[…] At NBAEM, we support customers with tailored advice to fit your specific welding needs. Our industrial-grade neodymium magnets come with specifications suited for various applications, especially useful for hands-free welding tools and reliable ferrous metal positioning. For more on magnetic basics, check out our detailed guide on magnetic hysteresis. […]