Neodymium magnets are used in many different industries because they are strong, small, and inexpensive. But it is important to make sure they are good magnets for the products you make. There are a few things you need to check to make sure you have a good neodymium magnet. You need to look at the performance characteristics, the way they look, and how they are made.

Performance

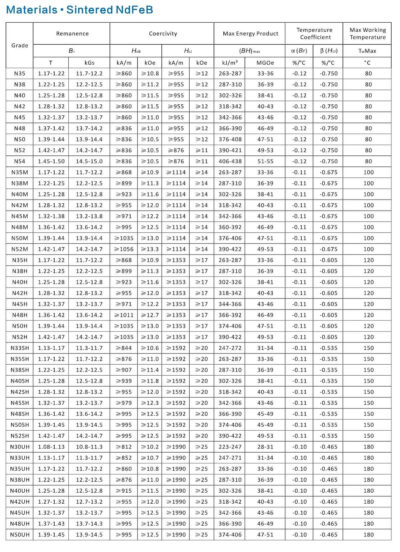

The first thing you want to check is the performance of the neodymium magnet. There are a lot of different grades of neodymium magnets. Grades range from N35 to N52. The higher the number, the stronger the magnet and the more expensive it is. However, just because you have a higher-grade magnet doesn’t mean it is better for your application. You need to know what you want the magnet to do. If you need a magnet to work in a high-temperature environment, you may need a magnet that can perform better at high temperatures. If you have a magnet that is going to be used in a small electronic device, you may need a magnet that is smaller and has a stronger magnetic field.

One test you can do is to use a Gauss meter to measure the strength of the magnet. Compare the strength you measure with the standardized sample data provided by the magnet manufacturer.

The next thing you want to check is the material composition of the magnet. The ratio of neodymium, iron, and boron in the magnet determines the strength of its magnetic field. The way the magnet was made will also affect its magnetic strength. The most common ways to make neodymium magnets are sintering, bonding, and melting. To make sure you have a good neodymium magnet, you want to buy magnets from a company that has good quality control.

Appearance

The next thing you want to check is the way the neodymium magnet looks. You want to check for cracks, chips, and how the magnet looks. Magnets are inspected visually for any defects in the surface finish or coating. They are tested for plating adhesion. They are tested for corrosion resistance. They put them in a salt spray and a humidity chamber to make sure the coating is going to stay on the magnet.

You also want to check the size of the magnet. The size and shape of the magnet are important because you want the magnet to fit where you are going to put it. Manufacturers measure the size of the magnet using calipers, micrometers, or a coordinate measuring machine (CMM). You want to make sure the magnet is going to fit properly where you are going to put it.

Magnetic Properties

The third thing you want to check is the magnetic strength of the magnet. There are a few different measurements you can use to find out how strong the magnet is. The three most common measurements are remanence (Br), coercivity (Hc), and maximum energy product (BHmax).

Remanence (Br) is the amount of magnetism left in the magnet after you take it out of the magnetic field.

Coercivity (Hc) is a measure of how hard it is to take the magnetism out of the magnet.

Maximum energy product (BHmax) is how much magnetic energy the magnet can store. High BHmax is important when you need a strong magnet.

Manufacturers use tools like vibrating sample magnetometers (VSMs) and permeameters to measure these properties. They take a magnet, put it in these machines, and run it through a bunch of tests. These tests create hysteresis curves.

Another test you can do is a pull force test. You put the magnet in a machine that measures how much force it takes to pull the magnet away from an object or hold the magnet on an object. This test tells you how the magnet will perform in your application.

One more test you can do is to use a Gauss meter. A Gauss meter measures the strength of the magnet’s magnetic field. This test tells you about the distribution of the magnet’s magnetic field and how strong the magnet is.

Coating

The next thing you want to check is the coating on the magnet. The coating is put on a magnet to protect it from corrosion and wear. You want to make sure the coating is going to stay on the magnet.

Manufacturers test the coating on the magnet to make sure it is going to stay on the magnet. They use a tape test or a scratch test to see if the coating is going to stay on the magnet.

They also test to see if the coating will protect the magnet from rust. They put the magnet in a salt spray and humidity chamber to see if the coating will keep the magnet from rusting.

Temperature

The next thing you want to check is how the magnet is going to work at high temperatures. Neodymium magnets are sensitive to high temperatures. When you expose a magnet to high temperatures, it loses some of its magnetic strength.

Manufacturers test how magnets perform at high temperatures. They do a test called thermal cycling. They put the magnet in an oven and heat it up to a certain temperature. Then they cool it down to see if the magnet will lose any of its magnetic strength. They also do a test called thermal shock. They put the magnet in a cold chamber and cool it down to a certain temperature. Then they put it in a hot chamber and heat it up to a certain temperature. They do this a few times to see if the magnet will lose any of its magnetic strength.

There are two things you can check to see how the magnet will perform at high temperatures. The first is the temperature coefficients. The temperature coefficients tell you how much the magnet will lose its magnetic strength when you expose it to high temperatures.

Compliance

The last thing you want to check is the compliance of the neodymium magnet. Manufacturers of neodymium magnets comply with international standards. The most common standards are ISO (International Organization for Standardization), IEC (International Electrotechnical Commission), and ASTM (American Society for Testing and Materials).

Manufacturers of neodymium magnets follow a quality control process. They check the raw materials they use to make the magnets. They have a manufacturing process that they follow. They document everything that happens during the manufacturing process. They test the magnets during the manufacturing process. They test the magnets when they are finished. They keep records of everything they test. They keep records of everything they do during the manufacturing process. They do this so they can find and fix any problems that happen during the manufacturing process. They also do this so they can show you, the customer, that they made the magnets the way they were supposed to make them.

In this chapter, we talked about how to check neodymium magnets to make sure they are good magnets for your products. We talked about performance, appearance, size, strength, coating, temperature, and compliance. Manufacturers of neodymium magnets check all these things to make sure they are selling you a good magnet. They want to make sure the magnet they sell you is going to work in your application.

[…] experience top-quality permanent magnet properties firsthand. Visit their product pages, like the quality of neodymium magnets, or contact their team today to get started with the best magnets available on the […]

[…] ensure your array performs as predicted, verifying the quality of Neodymium magnets is essential, as inconsistencies in grain structure can disrupt the precise field uniformity […]

[…] drastically reduces maintenance budgets. The longevity of these systems relies heavily on the quality of Neodymium magnets we utilize, ensuring stable torque performance over decades without […]