Are you curious about what is a bar magnet and why it’s so important in both everyday life and industry? Whether you’re a student trying to grasp basic physics concepts or a professional looking to understand magnetic materials better, this guide is for you. Bar magnets are among the simplest yet most fascinating types of permanent magnets, playing a crucial role from classroom experiments to advanced manufacturing processes.

In this blog, you’ll discover a clear explanation of bar magnets, their unique properties, how they work, and their many practical applications. Plus, as a trusted expert in magnetic materials, NBAEM will show you why understanding these magnets matters—and how our quality products can meet your needs. Ready to unlock the magnetic world? Let’s get started!

What is a Bar Magnet

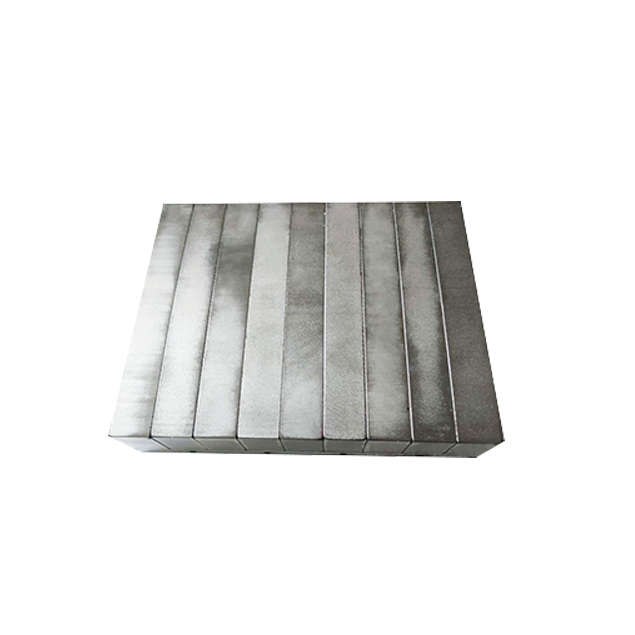

A bar magnet is a straight, rectangular permanent magnet that produces a stable magnetic field around it. I think of it as a simple, handy magnet you can hold in one hand — commonly used in classrooms, labs, and many industrial settings to demonstrate and basic magnetic effects.

Physical characteristics

- Shape and size

- Typically a long rectangular block or prism.

- Sizes range from a few millimeters (small lab magnets) to several inches or longer for industrial bars.

- The magnetization is usually along the long axis, so the two ends act as the main poles.

- composition

- Made from ferromagnetic materials that are commonly magnetized and hold magnetism:

- Alnico (aluminum, nickel, cobalt)

- Ferrite (ceramic)

–earth alloys like neodymium (NdFeB) - Steel or hardened iron in older or specialty bars

- Choice of material affects strength, temperature tolerance, and cost.

- Made from ferromagnetic materials that are commonly magnetized and hold magnetism:

How bar magnets generate magnetic fields

A bar magnet’s magnetic field arises from the alignment of microscopic magnetic moments inside the material. Atoms have tiny magnetic moments from electron spin and orbital motion. In ferrom materials these moments group into regions called domains. When most domains point the same way, their fields add up and the bar produces a strong, visible magnetic field. You can picture it like many tiny compass needles all lined up inside the bar.

Magnetic poles North and South

- Every bar magnet has poles: a North (N) and a South (S).

- Magnetic field lines leave the North pole and enter the South pole, creating a loop through space and back through the magnet.

- The field is strongest near the poles, which is why a bar magnet picks up iron objects most effectively at its.

- If you cut a bar magnet in two, each piece becomes a smaller bar magnet with its own North and South poles — you never get a single isolated pole.

Properties of Bar Magnets

Magnetic field and magnetic lines of force

A bar magnet produces a magnetic field around it. I describe it simply: field lines flow from the magnet’s North pole to its South pole outside the magnet and return through the magnet internally.

- Field strongest at the poles. That’s where a compass needle reacts most.

- You can visualize the lines with iron filings or a compass — they show the magnetic field of a bar magnet clearly.

Attraction and repulsion behavior

Bar magnets follow the basic rule: like poles repel, unlike poles attract.

- Opposite poles (N and S) pull together.

- Same poles (N–N or S–S) push apart.

- When a bar magnet meets ferromagnetic materials (iron, nickel, cobalt), it attracts and can induce temporary magnetism in them — that’s how paper clips stick.

Permanent magnet characteristics vs temporary magnets

Most bar magnets are permanent magnets, meaning they keep their magnetism without power. I point out the differences:

- Permanent magnets (e.g., neodymium, ferrite, Alnico) hold a magnetic field long-term.

- Temporary magnets (soft iron pieces) become magnetic only when near a magnet or current and lose it quickly.

- Permanent magnets have coercivity (resistance to demagnetization); high-coercivity materials keep their field better.

Magnetic strength factors

Magnetic strength of a bar magnet depends on several practical factors:

| Factor | How it affects strength |

|---|---|

| Material composition | NdFeB (neodymium) = very strong, Alnico = good for high temp, ferrite = lower strength but cheaper |

| Size and shape | Bigger volume or larger pole area usually means stronger pull; longer length can spread the field |

| Magnetization process | How it’s magnetized (field strength during manufacturing) sets maximum field |

| Temperature | High heat can weaken or permanently demagnetize some materials |

| Mechanical shock and corrosion | Drops or rust can reduce magnetic strength over time |

Practical tips I use: choose neodymium for compact, high-strength needs; pick ferrite for low cost and corrosion resistance; use Alnico when you need stability at higher temperatures. To check strength, use a gauss meter or compare lift capacity on a known weight.

How a Bar Magnet Works what is bar magnet

I’ll break down how a bar magnet actually works in simple terms. At the core, a bar magnet produces a magnetic field because many tiny magnetic regions inside it line up and act together.

Basic physics behind magnetism in bar magnets

- Atoms have tiny magnetic moments from electron spin and orbit. In most materials those moments point in random directions and cancel out.

- In a magnetized bar magnet those moments add up because groups of atoms, called domains, line up in the same direction, producing a net magnetic field.

- The magnetic field of a bar magnet flows from the North pole to the South pole outside the magnet and closes inside the magnet, creating visible lines of force if you map them with iron filings.

For more on permanent magnetic behavior see our page on what is permanent magnet.

Alignment of magnetic domains

- Domains are small regions with aligned atomic magnets. In unmagnetized metal they point various ways; in a bar magnet most domains point the same way.

- Magnetization happens during manufacture (heat treatment, strong magnetic fields) or by stroking one magnet across another. Materials with high coercivity keep domains aligned and stay magnetized.

- If domains get knocked out of alignment (heat, strong opposing fields, mechanical shock) the bar magnet can weaken or lose magnetism.

Interaction with ferromagnetic materials

- Bar magnets attract ferromagnetic metals like iron, nickel, and cobalt. Those metals’ domains are easy to reorient, so they become temporarily magnetized when near a bar magnet.

- That induced magnetism creates opposite poles in the nearby metal and causes attraction. This is why a bar magnet picks up paper clips or pulls on a steel screw.

- For details on what magnets are attracted to check our guide on what are magnets attracted to.

Practical demonstrations

- Paper clip test: bring the bar magnet close to a pile of paper clips. The clips become temporarily magnetized and stick to the magnet — a clear sign of induced magnetism.

- Compass test: place a compass near a bar magnet. The compass needle (itself a tiny magnet) rotates to align with the local magnetic field. If the bar magnet’s North pole faces the compass needle’s North, the needle will turn away (repel); opposite poles cause attraction.

- Like and unlike poles: hold two bar magnets near each other. Like poles (North-North or South-South) repel; unlike poles (North-South) attract. This demonstrates magnetic poles on bar magnet in action.

What is Bar Magnet Common Uses and Applications

I use bar magnets every day in demos and in-shop setups because they’re simple and reliable. Here’s where bar magnets show up most often and why they matter.

Educational tools and experiments

- Schools and science fairs: show magnetic field lines with iron filings or a compass, demonstrate attraction and repulsion, teach magnetic poles on bar magnet.

- Lab kits and STEM projects: ideal for hands-on lessons about magnetic field of bar magnet and properties of bar magnet.

- Easy demos: pick up paper clips, move a compass needle, or visualize domain alignment.

Everyday household uses

- Refrigerator magnets and clips: holding notes and photos ( made from ferrite or bonded materials).

- Magnetic clasps and closures: purses, cabinets, and small closures use compact bar-style magnets.

- Tool holders, magnetic hooks, and garage organizers: quick, durable solutions for home workshops.

Industrial and technological applications

- Prototyping motors and actuators: permanent magnet bars work well for small motor builds and test rigs.

- Sensors switches: used with reed switches, Hall effect sensors, and proximity detectors to trigger or calibrate devices- Data storage and actuators: permanent magnets play roles in actuator components and positioning systems (bar magnets often used in fixtures and prototypes rather than in the recording heads themselves).

Role in magnetic separators and manufacturing machinery

- Magnetic separators and sweeps: bar magnets are embedded in conveyor covers, trap plates, and drawer separators to pull ferrous contamination out of bulk material.

- Magnetic lifters and holders: simple bar magnet assemblies lift or hold ferrous parts in production lines.

- Fabrication aids: used in jigs fixtures, and magnetic clamps for welding and assembly.

Practical examples

- Paper clips and keys: quick pickup demo

- Compass interaction: show north and south poles

- Magnetic sweepers and separator plates: keep materials clean in food and recycling plants

NBAEM product relevance

At NBAEM we supply a wide range of bar magnet options suited for U.S schools, shops, and manufacturers:

- Materials: ferrite, bonded ferrite, Alnico, and NdFe options for different strength and cost needs.

- Custom sizes and magnetization patterns: bars cut and magnetized to fit separators, fixtures, or educational kits.

- Coatings and mounting: options for corrosion resistance or food-safe use when needed.

- Support: I can help match a bar magnet to your application, whether it’s a classroom demo, a prototype motor, or a magnetic separator in a production line.

Types of Magnets Compared to Bar Magnets

Here’s a clear comparison of common magnet types so you can see where a bar magnet fits.

Quick look at common magnet types

- Bar magnet

- Straight rectangular shape, visible North and South poles along the ends. Common permanent example used in labs and simple devices.

- Horseshoe magnet

- U-shaped, poles close together to concentrate the magnetic field for stronger lifting at the tips.

- Electromagnet

- Coil of wire that becomes magnetic when current flows. Field strength is adjustable and can be off.

- Disc magnet

- Flat, round shape used in sensors, speakers, and mounting applications.

- Neodymium magnet

- Very strong permanent magnet often made into bars, discs, or blocks. Learn more about neodymium magnet types and uses here: https://nbaem.com/what-a-neodymium-magnet/

You can also read about materials used across these types here https://nbaem.com/what-are-magnets-made-of/

Side-by-side comparison

| Feature | Bar magnet | Horseshoe | Electromagnet | Disc magnet |

|---|---|---|---|---|

| Field shape | Linear dipole | Concentrated between poles | Controlled by coil | Radial/flat |

| Best for | Basic demonstrations, holding | Lifting small loads, clamping | Heavy lifting, switches, variable control | Sensors, speakers, mounts |

| Strength range | Low to medium (depends on material) | Medium | Low to high | Low to high (neodymium discs strong) |

| On/off control | No | No | Yes | No |

| Cost | Low | Low–medium | Mediumhigh (depends) | Low–medium |

Advantages of bar magnets

- Simple and predictable magnetic field pattern (useful for teaching magnetic lines of force).

- Cheap and easy source for US schools, hobbyists, and light industrial uses.

- No power required, no controls, long-lasting as a permanent magnet.

- Available in many materials and grades, including neodymium and ferrite.

Disadvantages compared to other magnet types

- Less field concentration than a horseshoe magnet — weaker lifting at a single point.

- No on/off control like an electromagnet so not suitable where you need temporary magnetism.

- Size can limit strength — to get stronger fields you need bigger or higher-grade material (neodymium bars an exception).

- Shape may not fit compact or specialized applications where disc or custom shapes work better.

I usually recommend bar magnets when you need an inexpensive, reliable permanent magnet for demos, fixtures, or light holding tasks. If you need concentrated force, switchable fields, or compact form factors, consider horseshoe, electromagnet, or disc options instead.

Care and Handling of Bar Magnets

Tips to preserve magnetism

- I store magnets away from heat and strong alternating fields — heat and AC fields are the fastest ways to weaken a bar magnet.

- Keep magnets paired with opposite poles touching or use a soft-iron keeper to close the magnetic circuit older permanent magnets; this helps retain the magnetic field.

- Handle magnets gently; repeated knocks or drops can disorder magnetic domains and reduce magnetic strength.

Avoiding demagnetization

- Don’t expose bar magnets to temperatures near or above their Curie point — even short exposure to high heat can cause permanent loss of magnetism.

- Avoid strong opposing magnetic fields (large electromagnets or other high-strength magnets) that can partially or fully reverse your magnet’s polarity.

- Don’t hammer, bend or mechanically shock magnets — physical stress can demagnetize them over time.

Safe storage and handling best practices

- Use original packaging or padded separators to keep magnets from snapping togetheripping — for strong magnets I add spacers or cardboard between units.

- Label storage areas and keep magnets away from credit cards, HDDs, medical devices like pacemakers, and sensitive electronics common in U.S. homes and shops.

- Store on a non-magnetic shelf or in wooden boxes; avoid piling magnets directly on metal surfaces.

- When moving strong bar magnets, wear gloves and eye and move slowly to avoid pinch injuries.

I follow these simple steps and recommend them to customers across the U.S. — they keep magnet performance reliable and handling safe.

Why ChooseEM for Magnetic Materials and Bar Magnets

We make magnets for customers in the United States who need reliable performance, fast turnaround, and easy customization. Here’s why customers pick NBAEM for bar magnets and other magnetic materials.

What we bring to the table

- Proven manufacturing expertise

- Years of experience producing permanent magnets including neodymium, ferrite, and specialty grades.

- Modern production lines and quality controls to keep magnet strength consistent.

- Familiar with US supply needs, export logistics, and small- to large-volume orders.

- High quality materials and options

- We work with top magnet materials and can explain material tradeoffs — see our note on what are magnets made of for details.

- Custom sizes, coatings, magnetization patterns, and tolerance control to match your application.

- Industry-standard testing and documentation available on request (magnetic strength, remanence, coercivity).

- Customization and design support

- Cut, shape, magnetize, and assemble to your specs — from small bar magnets for prototypes to production runs for OEMs.

- Engineering help on choosing the right grade (for example neodymium magnets) and on optimizing magnetic performance for your device.

- Customer support and reliability

- Responsive sales and technical support that speaks plain English and helps with quotes, samples, and lead times.

- Consistent production quality and traceability — we back orders with documentation and practical advice for US customers.

Quick action steps

- Want product specs or a sample? Contact our sales team or request a catalog through our website.

- Have specific material questions? about our neodymium magnets or learn what are magnets made of to decide the best option.

Request a quote or catalog today and tell us your bar magnet size, material, and required magnetization — we’ll respond with lead time and pricing.

FAQs about Bar Magnets

What materials are bar magnets made of

Bar magnets can be made from several permanent magnet materials. Common options:

- Ferrite (ceramic) – inexpensive, widely used for fridge and classroom magnets.

- Alnico – iron, aluminum, nickel, cobalt mix; good temperature stability.

- Neodymium (NdFeB) – very strong, used where compact high strength is needed.

- Samarium Cobalt (SmCo) – high performance and temperature resistant.

For a deeper look at magnetic materials see what are magnets made of.

Can bar magnets lose their magnetism

Yes. Bar magnets can lose strength from:

- Heat (above the material’s Curie temperature)

- Strong mechanical shock or hammering

- Exposure to opposing magnetic fields

- Long-term gradual decay (small for good-quality permanent magnets)

If you want the physics behind loss and recovery of magnetization, check magnetic hysteresis.

How to make a bar magnet

You can magnetize a ferromagnetic bar a few ways:

- Stroke method: repeatedly stroke the bar with a strong permanent magnet in one direction.

- Electric coil: place the bar inside a solenoid and run DC current through the coil to align domains.

- Heat and cool in a magnetic field: used in controlled manufacturing.

Note: DIY methods work for small projects; industrial magnetizing needs proper equipment.

What is the difference between bar magnets and electromagnets

- Bar magnets are permanent: fixed magnetic poles, no power needed.

- Electromagnets use current in coils: you can switch them on/off and control strength with current.

- Use cases: bar magnets are simple and maintenance-free; electromagnets are used where adjustable or high fields are needed (cranes, MRI, industrial lifts).

How strong is the magnetic field of a typical bar magnet

Field strength varies by material and size. Typical surface field estimates:

- Small ferrite/alnico classroom bar: about 5–100 millitesla (mT) at the pole surface.

- Small neodymium bar: approximately 200–1000 mT (0.2–1 tesla) at the surface, depending on grade.

- Industrial or large magnets: can be higher and are rated by manufacturers.

If you need specific numbers for a product, check material grade and size—those determine magnetic strength.

Leave A Comment