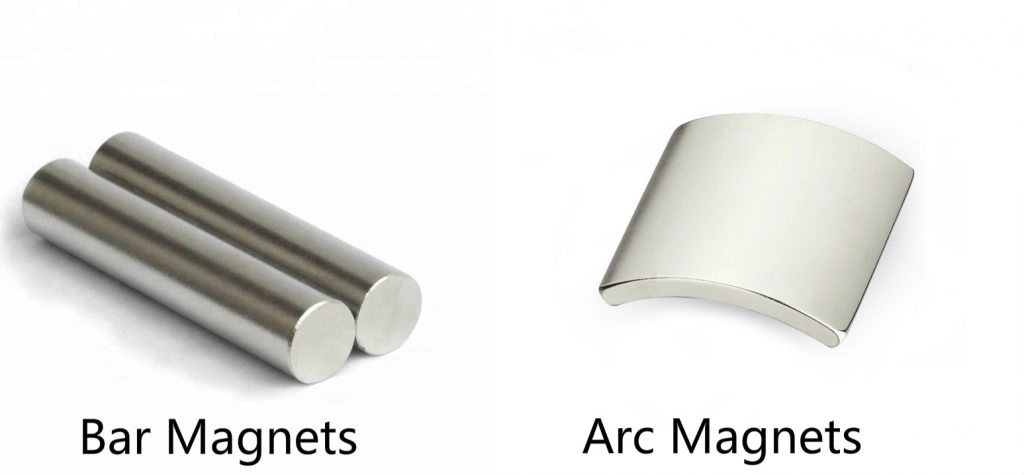

Understanding Neodymium Magnets Arc vs Bar

Neodymium magnets, also known as NdFeB magnets, are powerful permanent magnets made from an alloy of neodymium, iron, and boron. They are known for their exceptionally high magnetic strength compared to their size, making them a popular choice in applications where compact yet powerful magnets are required. You’ll find them in everything from electric motors and wind turbines to speakers, magnetic separators, and precision medical devices.

When comparing Neodymium Arc Magnets and Neodymium Bar Magnets, the primary difference lies in their shape and intended application.

- Arc magnets have a curved design, typically used to form segments of a ring when positioned together. This makes them ideal for creating a consistent magnetic field in rotating machinery such as motors, generators, and robotics systems.

- Bar magnets are straight and rectangular, focusing their magnetic field along the length of the magnet. This shape is better suited for applications like sensors, holding assemblies, and various magnetic separation processes.

The way these magnets are manufactured also differs. While both arc and bar types start with the same core NdFeB material, the shapes are achieved through different precision cutting and press-molding techniques. Arc magnets often require additional machining to achieve the exact curvature and tolerance needed for high-performance rotating equipment. Bar magnets are simpler to produce in uniform shapes, which can make them more cost-efficient in high-volume manufacturing.

Both shapes are coated—typically with nickel-copper-nickel, epoxy, or other protective layers—to enhance durability, resist corrosion, and maintain performance over time. The manufacturing method and finishing process directly influence the magnet’s final strength, dimensional accuracy, and suitability for specific working environments.

Physical and Magnetic Properties Compared

Shape and Dimensional Differences

Neodymium arc magnets are curved, often forming a partial circle segment. They’re sized to fit around rotors or stators, making them ideal for applications like electric motors. Neodymium bar magnets, on the other hand, are straight, with a simple rectangular or square cross-section. Bars vary a lot in length, width, and thickness, giving more flexibility for general-purpose use.

Magnetic Field Distribution and Strength

Arc magnets focus their magnetic field along the curve, creating an even, continuous magnetic path for rotating machinery. This shape maximizes efficiency in systems that rely on a circular magnetic field. Bar magnets produce a stronger pull at their poles, with the field spreading outward in a straight pattern. This makes them better for holding, sensing, or separating applications where a concentrated end-point force is needed.

Coating and Durability Differences

Both shapes are typically coated with nickel-copper-nickel for corrosion resistance. For harsher environments, epoxy or other special coatings are available. Arc magnets used in high-speed motors often have extra coating layers to handle vibration and friction, while bars tend to need less specialized protection unless used outdoors or in wet conditions.

Heat Resistance and Performance Stability

Standard neodymium magnets, whether arc or bar, work well up to around 176°F (80°C). High-temp grades can handle up to 428°F (220°C), but this is more common in arc magnets used in industrial motors where heat buildup is constant. Bar magnets in most applications aren’t exposed to the same sustained heat but still require stable performance to avoid demagnetization under stress.

Performance and Application Differences

Arc Magnets Applications

Neodymium arc magnets are shaped to match curved surfaces, making them perfect for rotating machinery. They’re commonly found in:

- Electric motors and generators – deliver strong, consistent magnetic fields for efficient rotation.

- Robotics – fit into compact, curved housings for precise movements.

- Wind turbines – boost power output by maximizing magnetic coverage in rotor designs.

Their curved design allows for better magnetic field overlap, improving performance in high-speed applications where efficiency matters most.

Bar Magnets Applications

Neodymium bar magnets offer a straight, uniform magnetic field, ideal for:

- Sensors and switches – provide stable readings in electronics.

- Medical devices – compact yet strong for MRI and specialized tools.

- Magnetic separators – capture metal particles in manufacturing lines.

Their rectangular shape makes them easier to align, especially in systems that need consistent poles across a flat area.

Installation and Mounting

- Arc magnets often require precision-matching to a curved surface. They may be glued or mechanically fixed into motor assemblies.

- Bar magnets install faster—flat surfaces make them suitable for basic adhesive, embedded slots, or bracket mounts.

Efficiency and Task Performance Benefits

| Magnet Type | Efficiency Advantage | Best For |

|---|---|---|

| Arc Magnet | Maximizes magnetic coverage in circular paths | Motors, turbines, robotics |

| Bar Magnet | Strong, even pull across flat zones | Sensors, separation, medical tools |

For curved-track applications, arc magnets reduce energy loss, while bar magnets give reliable pull where straight alignment is needed.

Advantages and Disadvantages Overview

Arc Magnets Pros and Cons

Pros:

- Perfect for creating continuous magnetic fields in round or curved assemblies, like electric motors.

- Efficient in space-limited designs where a curved fit is needed.

- Can improve motor efficiency and torque when shaped to the rotor/stator.

Cons:

- More expensive to produce due to custom shaping and manufacturing precision.

- Limited flexibility for reuse in other projects since they’re highly shape-specific.

- Can be harder to source in smaller quantities compared to standard shapes.

Bar Magnets Pros and Cons

Pros:

- Versatile, works for a wide range of applications from sensors to separators.

- Easy to mount, handle, and integrate into most assemblies.

- Generally more affordable due to simple design and easier mass production.

Cons:

- Not optimized for curved assemblies, which can lead to reduced efficiency in motor-type uses.

- May need additional mounting fixtures to hold firmly in place in dynamic applications.

Cost Implications and Lifecycle Analysis

Arc magnets typically have a higher upfront cost because of their complex manufacturing and machining requirements. However, when used in applications like high-performance motors, the return on efficiency can offset the cost over time. Bar magnets, being simpler and cheaper, offer better cost-per-unit but might require more units or additional engineering to achieve the same results in specialized setups.

In terms of lifespan, both shapes can last decades if coated properly and kept below their maximum operating temperature. If your environment involves higher heat, it’s worth reviewing magnets that can withstand high temperatures before deciding on shape and grade.

How to Choose Between Neodymium Arc Magnets and Bar Magnets

Choosing between Neodymium arc magnets and Neodymium bar magnets depends on how and where you’ll use them. The right pick comes down to fitting the magnet shape, strength, and durability to your specific application. Here’s what to look at:

Key Factors to Consider

- Application Purpose – Arc magnets are ideal for creating a circular magnetic path (motors, generators), while bar magnets are better for straight magnetic paths (holding, sensing, separation).

- Desired Field Shape – Arcs focus the field along curves, bars deliver a more linear pull.

- Pull Force Needed – Stronger force required? Choose the size and grade accordingly.

| Factor | Arc Magnets | Bar Magnets |

|---|---|---|

| Field Shape | Curved, follows arc | Straight, even pull |

| Common Use | Motors, alternators | Sensors, holding tools |

| Space Fit | Fits circular housings | Fits flat or linear spaces |

Environment and Operational Factors

- Temperature – Standard Neodymium handles up to ~80°C. For hotter environments (up to 200°C), request high-temp grades.

- Corrosion – If exposure to moisture or chemicals is likely, pick coated magnets (Ni-Cu-Ni, epoxy, or other protective layers).

- Wear and Stress – Consider mechanical stress in rotating setups (arc) or static installations (bar).

Size and Magnetic Strength

- Match magnet dimensions to the housing or device slot.

- Strength is measured in grade (N35, N42, N52). Higher grade, stronger pull — but mind the cost.

Customization and Batch Ordering from NBAEM

- Custom Shapes – NBAEM can produce arcs, bars, or hybrids to your specs.

- Coating Options – Nickel, zinc, epoxy, or custom finishes.

- Bulk Orders – Batch production for OEM projects keeps costs per piece down.

- Engineering Support – Drawings, prototypes, and advice to match the magnet to the job.

NBAEM Neodymium Magnet Product Range and Solutions

At NBAEM, we supply both Neodymium Arc Magnets and Neodymium Bar Magnets designed to meet the performance needs of U.S. industries. Our products are made from high-grade NdFeB material, delivering consistent strength, high precision, and reliable performance. Whether you need magnets for motors, sensors, medical devices, or industrial equipment, our range covers standard and custom specifications.

Our Arc and Bar Magnet Options

- Neodymium Arc Magnets: Designed for motors, generators, and rotor assemblies with exact curvature to fit your housing perfectly.

- Neodymium Bar Magnets: Ideal for fixtures, holding applications, sensing, and separation tasks, available in various grades and coating types.

Customization and Quality Standards

We can tailor:

- Shape, size, and grade for your magnetic strength requirements

- Coating options like Ni-Cu-Ni, epoxy, or other corrosion-resistant layers

- Tolerance precision for seamless integration in devices

Our magnets go through strict inspection processes to ensure tight tolerances, consistent magnetization, and long-term durability, following ISO and industry standards.

Real-World Applications and Results

We’ve worked with:

- A U.S. electric vehicle parts maker using our arc magnets for high-efficiency motor rotors

- A robotics company customizing bar magnets for compact sensor arrays

- An industrial filtration firm applying long bar magnets for high-volume magnetic separation

Each project benefited from improved performance stability and reduced maintenance downtime.

Simple Ordering with Dedicated Support

Ordering from NBAEM is straightforward:

- Send your specs or application needs

- We provide design support and confirm details

- Quick production and global shipping with secure packaging

Our U.S. clients value our responsive technical support, clear communication, and flexible production runs, whether for small pilot orders or bulk shipments.

FAQ Section

What is the typical lifespan of an arc vs bar magnet

Both neodymium arc magnets and bar magnets can last 10–20 years or more if they’re used within their rated limits. The main factors that affect lifespan are heat, corrosion, and physical impact. Arc magnets in motors tend to face more heat cycles, so making sure they’re properly coated and cooled helps extend life. Bar magnets generally see less mechanical stress, so they often hold their magnetism a bit longer in low-wear applications.

Can arc and bar magnets be combined in one device

Yes. Many products pair arc magnets with bar magnets to get specific magnetic field shapes. For example, an electric motor might use arcs for the rotor and bars for sensors or positioning. The key is matching their magnetic grades and ensuring the magnetic fields don’t work against each other.

Are there industry standards governing their use

Yes. Neodymium magnets typically follow industry standards like ISO 9001 for manufacturing quality, and the IEC and ASTM guidelines for performance and safety. These standards help ensure consistent strength and reliability, especially in sectors like automotive, aerospace, and medical devices.

Shipping packaging and handling tips from NBAEM

- Use protective coatings (Ni-Cu-Ni, Epoxy, etc.) before packaging to avoid corrosion during transit.

- Separate magnets with spacers to prevent them from snapping together and chipping.

- Shield magnetic fields in packaging when shipping by air or internationally to meet carrier safety rules.

- Never drop or smack magnets together—even small neodymium magnets can chip or crack.

- For U.S. customers, NBAEM uses foam-lined boxes and magnetic shielding materials to keep your order safe and compliant with shipping regulations.

Leave A Comment