Understanding N55 Magnets What Makes Them Unique

When people look for the strongest neodymium magnets on the market, they often come across the grade N55. The “N” in N55 stands for neodymium, and the number represents the magnet’s strength rating based on the industry grading system, which runs from N35 (weaker) to N55 (currently the highest commercially available). Simply put, the higher the number, the greater the magnetic pull and energy density.

What N55 Means in Strength and Performance

An N55 magnet delivers exceptional magnetic strength. It has one of the highest magnetic flux density values available, meaning it can generate a stronger magnetic field in a smaller size compared to lower grades. This allows you to achieve powerful attraction without the need for a bulky magnet.

Key Specifications of N55 Magnets

Property

N55 Typical Value

Magnetic Flux Density (Tesla)

~1.45 T

Coercivity (kOe)

12–14 kOe

Max Energy Product (BHmax)

~52–55 MGOe

Residual Induction (Br)

14.5–14.9 kGs

These metrics translate into unmatched holding force, excellent resistance to demagnetization, and compact design options for advanced applications.

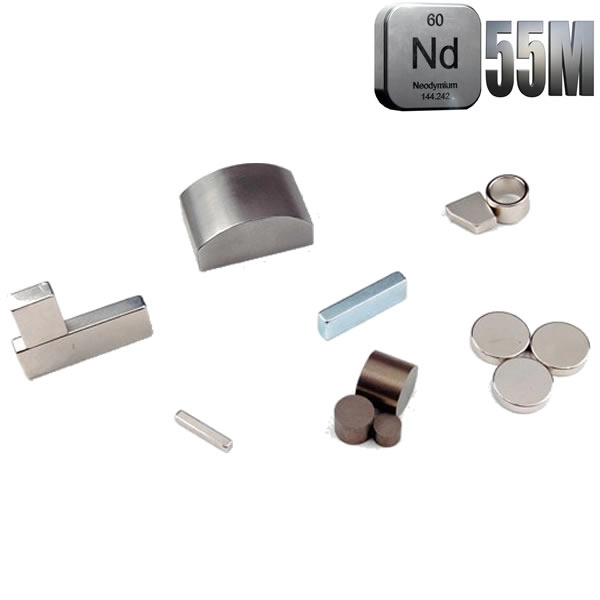

Physical Characteristics

N55 magnets are available in many sizes and shapes, including discs, blocks, rings, and custom forms to fit different industrial or consumer uses. To protect against corrosion, they are typically coated with nickel-copper-nickel, epoxy, or other specialized finishes depending on the environment. This makes them suitable for demanding applications where durability and reliability are non-negotiable.

Benefits and Advantages of N55 Magnets

How N55 Compares to Other Grades

N55 magnets sit at the top of the neodymium magnet scale. Compared to N52, N50, and N48 grades, they deliver noticeably higher magnetic strength, making them the go-to choice when maximum performance is needed.

| Grade | Maximum Energy Product (BHmax) | Relative Strength | Common Use Case |

|---|---|---|---|

| N48 | ~48 MGOe | Good | General industry |

| N50 | ~50 MGOe | Strong | Precision tools |

| N52 | ~52 MGOe | Very Strong | Heavy lift, motors |

| N55 | ~55 MGOe | Strongest | High-demand engineering, specialty devices |

Strength and Performance in Real Use

- Industrial applications: Handles jobs where smaller magnets can’t cut it, such as compact yet high-power motors.

- Consumer products: Lets manufacturers design sleeker gadgets without compromising holding power.

- High pull force: Offers stronger grip for the same size compared to lower grades, reducing the number of magnets needed.

Long-Term Reliability

- Holds magnetic strength over years of use.

- Highly resistant to demagnetization when used within its rated temperature limits.

Heat Resistance

- Standard N55 magnets typically handle operating temps up to about 80°C (176°F) before strength starts to drop.

- For higher heat environments, special high-temp N55 variants are available from some suppliers.

This balance of maximum strength, stable performance, and compact size is why N55 magnets are favored for U.S. engineering projects, advanced electronics, and high-efficiency machinery.

Common Applications of N55 Magnets

N55 magnets are used when you need maximum strength in a compact size. Their high magnetic force makes them a popular choice across different industries in the U.S., from advanced manufacturing to everyday DIY projects.

Electronics and Sensor Technologies

In electronics, N55 magnets are used in precision sensors, microphones, speakers, and hard drives. Their strong magnetic field allows for accurate readings and compact designs without losing performance.

Electric Motors and Generators

High-performance motors and generators—like those in robotics or aviation—benefit from N55 magnets because they can produce more torque and efficiency while keeping components small and lightweight.

Renewable Energy Equipment

N55 magnets are common in wind turbines and other renewable energy systems. Their ability to maintain strong magnetic force over time makes them reliable in continuous operation, where efficiency and durability matter most.

Medical Devices and Instrumentation

From MRI machines to surgical instruments, N55 magnets are used where precision and strong magnetic fields are essential. Their reliability supports both diagnostic and treatment equipment.

Automotive Industry

Electric vehicles, hybrid drivetrains, and advanced driver-assistance systems (ADAS) use N55 magnets for efficient motor performance, sensors, and energy storage solutions.

DIY Projects and Hobbyist Uses

For hobbyists, N55 magnets are favorites for custom tools, model building, and engineering experiments. They are ideal for projects that require a lot of strength in a small footprint.

Buying Guide for N55 Magnets What to Consider

When you’re looking to buy N55 magnets, knowing what to check before placing an order can save you money and time—especially if you’re sourcing from overseas suppliers like NBAEM. Here’s what matters most for US buyers.

Check Quality Certifications

For magnets that meet safety and environmental standards, look for:

- ISO 9001 – Confirms the manufacturer’s quality management system.

- RoHS – Ensures the magnet is free from restricted hazardous substances.

- REACH – Compliance with European chemical safety regulations.

These are important if you’re using magnets in products that will be sold in the US and abroad.

Customization Options

N55 magnets can be made to fit your exact needs. Leading suppliers like NBAEM can offer:

- Sizes: From tiny discs to large blocks.

- Shapes: Disc, block, ring, arc, custom-cut.

- Coatings: Nickel-Copper-Nickel (NiCuNi), epoxy, zinc for corrosion protection.

- Magnetization direction: Axial, diametral, and custom alignments for specific applications.

Bulk vs. Small Orders

- Bulk purchasing lowers per-unit cost and ensures a consistent batch for large projects.

- Small orders are better for prototypes, testing, or DIY projects.

If you plan to scale up, start small and move to bulk once you confirm performance.

How NBAEM Ensures Quality

NBAEM uses strict incoming material inspection, automated production lines, and multiple round magnetic property testing. Each batch is tracked for consistency, which is critical for industries like electronics, motors, and medical devices.

What Affects Price

The cost of N55 neodymium magnets depends on:

- Raw material prices: Mainly neodymium, praseodymium, and dysprosium.

- Coating choice: Anti-corrosion coatings add cost.

- Complexity of customization: Unusual shapes or tight tolerances require more processing.

- Order volume: Higher quantities mean better pricing per piece.

Handling Safety and Storage Tips for N55 Magnets

N55 magnets are incredibly strong, and handling them the wrong way can cause injuries or damage. Here’s what to keep in mind to stay safe and keep your magnets in top shape.

Safety Precautions During Handling

- Watch for pinching hazards – N55 magnets can snap together with force, so keep fingers and skin clear.

- Keep away from electronics – They can damage hard drives, credit cards, and other magnetic storage.

- Use protective gear – Wear gloves and eye protection if handling larger magnets.

- Separate carefully – Slide magnets apart instead of pulling them straight.

Proper Storage Tips

- Store with spacers – Use non-metallic spacers to reduce magnetic pull when stacking.

- Keep in a dry, cool place – Moisture can damage coatings, leading to corrosion.

- Avoid high heat – N55 magnets lose strength if exposed to temperatures above their max rating (usually around 80°C/176°F unless specially made for higher heat).

- Shield with a keeper – For larger magnets, use a steel keeper to close the magnetic circuit and reduce stray fields.

Environmental and Disposal Considerations

- Recycle when possible – Neodymium magnets can be processed and reused to reduce waste.

- Do not incinerate – Extreme heat can cause them to break down and release fumes.

- Follow local regulations – Check local scrap metal or hazardous waste facilities for proper disposal options.

Why Choose NBAEM as Your N55 Magnet Supplier

If you’re looking for strong, high-quality N55 magnets at a fair price, NBAEM is one of the most reliable choices. They’re a China-based manufacturer with years of experience supplying the U.S. market, and they focus on both performance and consistency.

Manufacturing Capabilities and Product Range

NBAEM produces a full range of neodymium magnet grades, with N55 being their strongest. Their facilities are equipped for precision manufacturing, meeting ISO, RoHS, and REACH standards. You can order magnets in various shapes, sizes, and coatings, or request custom magnetization directions for more specialized uses.

Product range includes:

- N35 to N55 rare earth magnets

- Custom shapes: discs, blocks, rings, countersunk, and more

- Coatings: nickel, epoxy, gold, and custom options

- High-temperature grades for demanding applications

Customer Feedback and Case Studies

Many U.S. clients in sectors like electronics, automotive, and renewable energy report consistent strength and durability from NBAEM magnets. Some case studies highlight improved motor efficiency and reduced equipment failures after switching to NBAEM’s N55 magnets.

Support and Consulting

You can reach their tech team for help with:

- Choosing the right grade for your project

- Custom designing magnets for specific machinery or tools

- Troubleshooting magnetic performance issues

Shipping Advantages

NBAEM handles both bulk and small orders with flexible lead times.

Shipping benefits:

- Fast delivery to U.S. customers via air freight for urgent orders

- Cost-effective ocean freight for bulk shipments

- Strong export packaging to prevent damage during transit

This focus on quality, customization, and reliable global shipping makes NBAEM a trusted partner for anyone needing top-tier N55 magnets in the United States.

Frequently Asked Questions about N55 Magnets

What is the maximum temperature N55 magnets can handle

Most standard N55 neodymium magnets can work up to around 80°C (176°F) before starting to lose strength. If you need them for hotter environments, you’ll want a high-temp version that can go up to 120–150°C depending on the coating and grade tweak.

How much stronger is N55 compared to N52

N55 is about 5–6% stronger than N52 in terms of maximum energy product (BHmax). That difference might seem small, but if you’re working in a space where magnet size is limited, that bump in strength can make a big impact.

Can N55 magnets be used in high vibration environments

Yes, but you’ll need proper mounting and protection. The magnetic bond itself isn’t weakened by vibration, but neodymium is brittle, so impacts or constant movement can cause chipping or breakage if the magnet isn’t secured well. Using a strong casing or embedding the magnet helps a lot.

How to demagnetize or recycle N55 magnets safely

- Demagnetizing: Apply enough heat above the magnet’s Curie temperature (over 310°C / 590°F) or use an alternating current (AC) degausser.

- Recycling: Never throw them in the trash. N55 magnets contain rare earth materials that can be recovered. Look for a metal recycler or e-waste facility that handles neodymium magnets.

- Safety tip: Keep in mind that heating to demagnetize releases fumes — only do it in a well-ventilated space with proper protective gear.

[…] deeper insights on how premium neodymium magnets perform, check out the detailed breakdown of N55 , the higest grade of sinter NdFeB magnets, a favorite for reliable, strong magnetic door […]