Is zinc metal magnetic? You might think all metals are attracted to magnets, but the truth is far more interesting. Zinc plays by different rules—it’s not like iron or nickel, and its behavior in a magnetic field might surprise you. Whether you’re in manufacturing, engineering, or just curious about magnetic materials, understanding zinc’s unique properties can save you from costly mistakes and open new opportunities for design. Let’s cut through the guesswork and see exactly where zinc’s magnetism stands—and why it matters.

Fundamentals of Magnetism

Magnetism is a physical phenomenon where certain materials produce a force that can attract or repel other materials due to the motion of electric charges, primarily electrons. At its core, magnetism comes from the alignment and spin of electrons within an atom. Depending on how these electrons behave, materials can show different types of magnetic behavior.

Main types of magnetic behavior include:

- Ferromagnetism – Strong magnetism found in metals like iron, cobalt, and nickel where electron spins align in the same direction.

- Paramagnetism – Weak attraction to magnetic fields caused by unpaired electrons, seen in materials like aluminum.

- Diamagnetism – Weak repulsion from a magnetic field due to electrons pairing up, canceling out magnetic moments, as in copper or zinc.

- Antiferromagnetism – A property where magnetic moments align in opposite directions, canceling each other out, resulting in no net magnetization.

Most metals exhibit some form of magnetic response, but the strength and type vary widely. Ferromagnetic metals can hold permanent magnetization, while diamagnetic and paramagnetic metals only show effects when exposed to an external magnetic field.

In materials science and engineering, understanding a metal’s magnetic properties is crucial. These properties influence:

- Selection of metals for electrical and electronic devices

- Compatibility with magnetic sensors or data storage systems

- Sorting and metal recycling processes that use magnets

- Design of magnetic shielding or non-magnetic components

For a deeper look at these behaviors, see the detailed explanation in Types of Magnetic Materials, which breaks down how metals respond to magnetic fields in industrial and scientific contexts.

The Magnetic Properties of Zinc

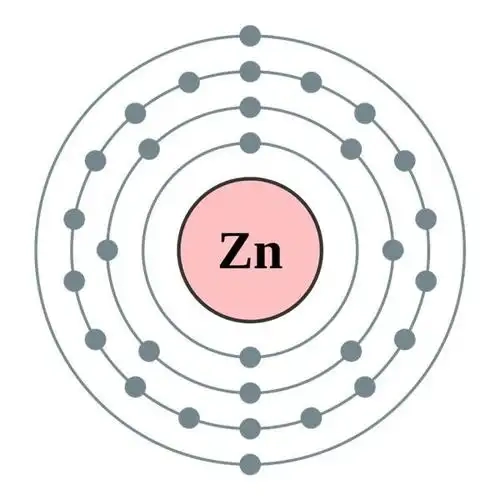

Zinc is a bluish-white metal that’s strong, corrosion-resistant, and widely used in coatings and alloys. From a chemistry standpoint, it has a filled electron shell structure, which affects how it reacts to magnetic fields. Zinc is not ferromagnetic, meaning it won’t stick to a magnet like iron, nickel, or cobalt do.

Instead, zinc is classified as a diamagnetic metal. This means it actually creates a very weak opposing magnetic field when exposed to one, giving it a slight negative magnetic susceptibility. You can’t feel or see this effect without sensitive instruments, but research and laboratory tests confirm it. Scientists have measured zinc’s susceptibility at around –0.000014 (SI units), which is far lower than materials with noticeable magnetic pull.

Because of this, zinc won’t interfere with magnetic sensors and isn’t attracted to magnetic separators, a fact that plays an important role in manufacturing, recycling, and electronics applications.

Why Zinc’s Magnetism or Lack Thereof Matters

Zinc’s non-magnetic nature plays a bigger role in industry than most people realize. Because zinc is diamagnetic, it doesn’t stick to magnets, which makes it ideal for certain applications where magnetic interference could be a problem.

In industrial applications, zinc’s most common use is galvanization—coating steel to prevent rust. Its lack of magnetism means the magnetic properties of the steel underneath aren’t affected. In alloy production, adding zinc can improve corrosion resistance without changing how the final product reacts to magnets. In electronics, zinc is valued for making non-magnetic housings or brackets that won’t interfere with sensors, coils, or magnetic data storage.

On the recycling side, non-magnetic metals like zinc are easy to separate from ferrous materials using magnetic sorting systems. Scrap yards and processing plants run magnets over conveyor belts to pull out steel and iron, leaving zinc and other non-magnetic metals for separate collection.

Zinc’s diamagnetism can also be useful in magnetic shielding or in parts of machines and devices that must remain unaffected by nearby magnetic fields. This makes it a go-to choice for certain precision instruments, aerospace assemblies, and specialized manufacturing equipment.

Comparing Zinc with Other Common Metals

Zinc’s magnetic behavior is very different from metals like iron, nickel, and cobalt. Those three are ferromagnetic, which means they strongly attract to magnets and can stay magnetized. Zinc, on the other hand, is diamagnetic, meaning it weakly repels magnetic fields and has no lasting magnetism.

Here’s a quick look:

| Metal | Magnetic Type | Magnetic Strength | Common Uses |

|---|---|---|---|

| Iron | Ferromagnetic | Strong | Steel, tools, construction |

| Nickel | Ferromagnetic | Strong | Coins, batteries, stainless steel |

| Cobalt | Ferromagnetic | Strong | Magnets, alloys, batteries |

| Copper | Diamagnetic | Very weak repulsion | Wiring, electronics |

| Aluminum | Paramagnetic | Weak attraction | Aerospace, cans, frames |

| Zinc | Diamagnetic | Very weak repulsion | Galvanizing, die-casting, alloys |

- Ferromagnetic metals like iron, nickel, and cobalt are easy to sort using magnets.

- Diamagnetic metals like zinc and copper won’t stick to magnets, which can be useful in non-magnetic parts.

- Paramagnetic metals like aluminum have a slight attraction but not enough for practical magnet sorting.

These differences affect industrial applications—from manufacturing to recycling—since magnetism can determine how materials are processed, separated, or used in devices where magnetic interference is a concern.

Applications and Limitations of Zinc with Respect to Magnetism

Zinc’s diamagnetic nature means it doesn’t get attracted to magnets, making it useful in industries where magnetic interference is a problem. In electronics, for example, zinc parts won’t affect magnetic sensors or disrupt magnetic fields in delicate devices. This is also an advantage in precision instruments, medical equipment, and aerospace components that require non-magnetic materials for accuracy and safety.

In manufacturing, zinc’s non-magnetic properties are irrelevant in uses like galvanization, where the focus is on corrosion resistance, not magnetism. It also works well in alloys where non-magnetic characteristics are desirable.

Examples where zinc’s non-magnetic nature is preferred:

- Casings and brackets near magnetic sensors or compasses

- Components in MRI-safe equipment

- Parts in navigation systems where steel would cause interference

Potential challenges with zinc in magnetic environments:

- Cannot be separated from waste or scrap using magnetic sorting

- Won’t help in magnetic shielding applications where ferromagnetic metals are needed

- Not suitable where magnetic attraction is part of the design or function

For U.S. manufacturers, especially in electronics, defense, and specialized tooling, choosing zinc for its lack of magnetism can solve interference problems and meet strict industry requirements.

NBAEM Role and Expertise

At NBAEM, we work with both magnetic and non-magnetic metals, including diamagnetic options like zinc. Our portfolio covers a wide range of materials — from strong ferromagnets like iron, nickel, and cobalt to metals with low or zero magnetic response for specialized industries. This variety helps our U.S. customers choose exactly what works for their applications, whether they need magnetic attraction or complete magnetic neutrality.

Understanding how each metal reacts to a magnetic field is key when selecting materials for manufacturing, electronics, construction, or recycling. For example, knowing that zinc is non-magnetic can prevent interference in sensitive equipment, improve product safety, and streamline sorting processes.

We provide tailored guidance to match the right material to your project’s needs. If you’re in the U.S. and need expert advice on magnetic materials or non-magnetic metals for manufacturing, our team is ready to help with sourcing, technical support, and bulk supply. Contact NBAEM for consultation or material specifications to ensure you get the best fit for your operation.

Leave A Comment