Ever heard of a magnet in a cow’s stomach and wondered why it’s there?

It’s not some strange farm myth—it’s a proven livestock health solution that can save farmers thousands of dollars. In fact, a small device called a rumen magnet can protect cattle from deadly hardware disease by trapping harmful metal objects before they cause damage.

In this post, you’ll quickly learn what a rumen magnet is, why it’s used, and how it works inside a cow’s stomach—plus the real-world benefits for both animal health and farm productivity.

Let’s jump right in.

What is a Rumen Magnet

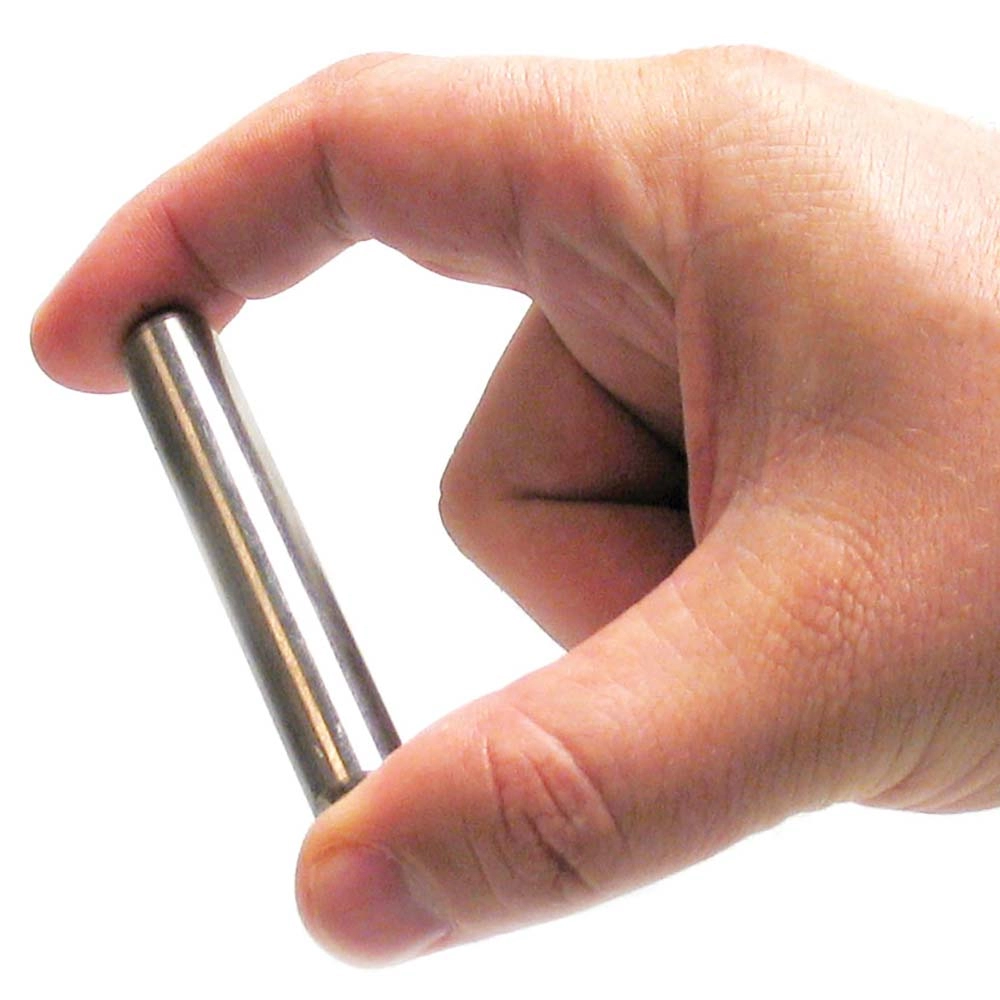

A rumen magnet is a veterinary tool placed inside a cow’s stomach to help prevent a condition known as hardware disease. It is a small, smooth, and non-toxic magnetic device designed to stay in the animal’s stomach for life without causing harm. Once administered, the magnet sits in the reticulum, one of the cow’s four stomach compartments, and works to attract and trap metal objects the cow may accidentally swallow, such as small nails, wires, or staples.

Rumen magnets are typically made from strong permanent magnetic materials. The most common types used in modern livestock care include:

- Neodymium magnets – extremely strong rare-earth magnets with high holding power in a compact size

- Ferrite (ceramic) magnets – durable and cost-effective with good resistance to corrosion

- Alnico magnets – made from aluminum, nickel, and cobalt, valued for temperature stability

For this application, magnets must be permanent and powerful because they need to work continuously for the life of the animal. Weak magnets may fail to hold sharp metal fragments in place, allowing them to damage the stomach lining or migrate into vital organs. A strong magnetic pull ensures that dangerous debris remains firmly attached to the magnet, greatly reducing the risk of injury or infection.

Why Are Magnets Placed in Cow Stomachs

Cattle sometimes eat small pieces of metal by accident—things like nails, wires, or machinery fragments that end up in feed or pasture. This can lead to hardware disease, a serious condition where the metal settles in the reticulum (one of the cow’s stomach compartments) and can puncture the stomach wall. That piercing can cause internal infection, swelling, or severe pain, and in many cases, it can be fatal if not prevented or treated.

A rumen magnet sits in the reticulum and attracts these metal objects before they can puncture tissue. Once the pieces stick to the magnet, they stay put, preventing further injury. Cows can carry these magnets for years without harm, as they are made to be safe inside the stomach environment.

Studies have shown that using cow stomach magnets can cut hardware disease cases by more than 50–70% in herds where it’s a risk. This means healthier cattle, fewer emergency treatments, and less loss of productivity for farmers.

How Does the Magnet Work Inside the Cows Stomach

Cows have a four-part stomach, but when we talk about a rumen magnet, it sits mainly in the reticulum — the second compartment, right next to the rumen. That’s where most swallowed metal debris, like nails or wire, tends to settle due to the cow’s stomach movement and gravity.

Once in place, the magnet creates a strong, constant magnetic field. Any ferrous metal objects (iron, steel, etc.) that the cow eats by accident are pulled toward it and stay stuck there instead of moving through the stomach and poking into tissue. This keeps sharp metal from puncturing the stomach wall and causing hardware disease.

A good-quality rumen magnet is made from strong, permanent magnetic materials like ferrite or neodymium. It’s designed to stay inside the reticulum for the rest of the cow’s life — often 8 years or more — without losing strength. Most are sealed with a smooth, corrosion-resistant coating so they won’t break down in the acidic, moist environment of the stomach.

Because the magnetic field works 24/7 and doesn’t wear out, one magnet is typically enough for a cow’s lifetime when given at the right age.

Application and Administration of Rumen Magnets

Rumen magnets are usually given to cattle as a preventive measure against hardware disease, especially before they reach breeding or peak production age. Most U.S. farmers administer them to young cattle between 6 months and 1 year old, before the animals are turned out to graze or start on full feed. This timing ensures the magnet can catch stray metal early and stay effective for the life of the animal.

How and when to give a magnet

- Beef cattle – Often during weaning, branding, or pre-pasture turnout.

- Dairy cattle – Before entering the milking herd, usually as part of herd health protocols.

- Once given, the magnet stays in the reticulum permanently and does not need to be replaced unless specifically advised by a vet.

Recommended dosage

- One magnet per animal is standard, regardless of breed.

- Size selection depends on cattle age and weight—standard 3-inch ferrite or neodymium-coated magnets work for adult cattle, while smaller versions are used for younger stock.

Safety and handling tips

- Always use a smooth-coated veterinary-grade magnet to avoid injury during insertion.

- Administer using a balling gun for proper placement and to prevent choking.

- Keep magnets clean and free from rust before use—moisture-damaged magnets should not be administered.

Vet supervision and best practices

- Work with a veterinarian when adding rumen magnets to your herd health program.

- Use magnets as part of a full prevention plan along with good feed management to reduce the chance of cattle eating scrap metal.

- If illness or digestion issues persist after magnet administration, have the cow examined to rule out other causes.

This approach helps cattle owners in the U.S. protect herd health, reduce veterinary costs, and improve productivity without frequent re-treatment.

Benefits of Using Magnets in Cow Stomachs

Using a rumen magnet in cattle is one of the simplest and most cost‑effective ways to prevent hardware disease and keep livestock healthy. Farmers across the U.S. rely on them because they work quietly in the background for years without extra effort.

Key Benefits

1. Prevents Hardware Disease

- Catches nails, wires, and other stray metal before it punctures the cow’s stomach lining.

- Reduces the risk of infection, pain, and loss of appetite in cattle.

2. Improves Animal Welfare

- Keeps cows comfortable and stress‑free by preventing chronic stomach injuries.

- Leads to better feed intake and overall health.

3. Cuts Treatment Costs and Losses

- Less need for antibiotics, surgeries, or emergency vet bills.

- Lower death rates from hardware disease.

4. Boosts Productivity and Longevity

- Healthy cows produce more milk and maintain better weight gain.

- Extends useful herd life, reducing replacement costs.

5. Environmental and Economic Benefits

- Fewer losses mean less waste and better use of feed resources.

- More profit per cow with minimal upfront investment.

| Benefit Area | Impact on Farm |

|---|---|

| Health | Prevents internal injuries from swallowed metal |

| Cost Savings | Cuts vet bills and death losses |

| Productivity | Higher milk yield and faster weight gain |

| Longevity | Extends cow lifespan in herd |

| Sustainability | Reduces waste, maximizes feed use |

This is why a cow stomach magnet is standard practice on U.S. dairy and beef farms — it’s a small tool with a big return.

Types of Magnets Suitable for Veterinary Use

When it comes to rumen magnets for cattle, not all magnets are built the same. The most common materials are neodymium, ferrite (ceramic), and other strong magnetic alloys.

- Neodymium magnets – Extremely strong, compact, and reliable, making them effective at holding even very small steel or iron fragments in the cow’s stomach.

- Ferrite magnets – Lower in cost and corrosion-resistant, but generally not as powerful as neodymium.

- Special magnetic alloys – Designed for a balance of strength and durability for long-term use inside livestock.

For U.S. livestock operations, strength and safety are top priorities. NBAEM magnets stand out because they combine:

- Superior magnetic strength – Strong pull force to capture more harmful metal pieces.

- High durability – Resistant to demagnetization, so they keep working for years inside the animal.

- Bio safety – Manufactured with animal health standards in mind, ensuring no toxic materials or sharp edges.

A big factor for rumen magnets is protective coating. Coatings like stainless steel, epoxy, or plastic prevent corrosion from stomach acids and keep the magnet intact. This is especially important for dairy and beef cattle that may keep the magnet for their entire lifetime.

Using the right magnetic material and coating ensures better protection against hardware disease, fewer veterinary interventions, and peace of mind for ranchers and dairy farmers.

Common Misconceptions and FAQs

Do magnets harm the cow

A properly placed rumen magnet doesn’t harm the cow. It just sits in the reticulum and holds small bits of swallowed metal so they can’t injure the stomach lining. Cows don’t feel it, and it doesn’t affect digestion. Problems only arise if the magnet is damaged or not designed for veterinary use.

Can magnets be removed

In most cases, rumen magnets are meant to stay in for life. They’re durable, corrosion-resistant, and keep working for years. Removal would require surgery, which is rarely necessary unless there’s a complication — and that’s uncommon when quality magnets are used.

How often should magnets be administered

Generally, cattle only need one magnet for their lifetime. Farmers usually give it to young cattle (around 6 months old) before they start grazing or eating feed that could contain stray metal.

Are there alternatives to magnets for hardware disease prevention

Other options include:

- Strict feed and pasture inspection to remove metal objects

- Using feed magnets in processing equipment

- Cleaner feeding environments to reduce risk

However, these methods aren’t as foolproof as a rumen magnet, which protects the cow from metal even if a piece is missed.

How NBAEM Supports the Livestock Industry with Premium Magnetic Materials

NBAEM is a leading supplier of magnetic materials, known for producing high-performance magnets for industrial, medical, and agricultural use — including veterinary magnets for cattle health. With years of expertise in designing and manufacturing neodymium, ferrite, and other magnetic alloys, they provide solutions that meet the specific needs of U.S. livestock farmers.

For the cattle industry, NBAEM offers custom manufacturing of rumen magnets, giving farmers and veterinarians options that match the size, strength, and coating requirements for different herd types. Whether it’s a smooth, corrosion-resistant coating for long-term use in the cow’s reticulum or magnets designed for young heifers, they tailor their products to ensure maximum durability and safety inside the animal’s stomach.

Quality control is a top priority. Each veterinary magnet is made under strict safety and hygiene standards, ensuring no harmful coatings or weak points that could compromise animal health. From material sourcing to final inspection, NBAEM follows ISO-level quality protocols so livestock owners can rely on consistent performance and protection against hardware disease.

If you’re looking for reliable, high-strength rumen magnets backed by expert engineering, NBAEM is equipped to deliver. You can learn more about their neodymium magnet expertise here.

Leave A Comment