Advanced Magnetic Materials for Global Industries

NBAEM is a leading Chinese supplier of high-performance magnetic materials and custom solutions for diverse applications.

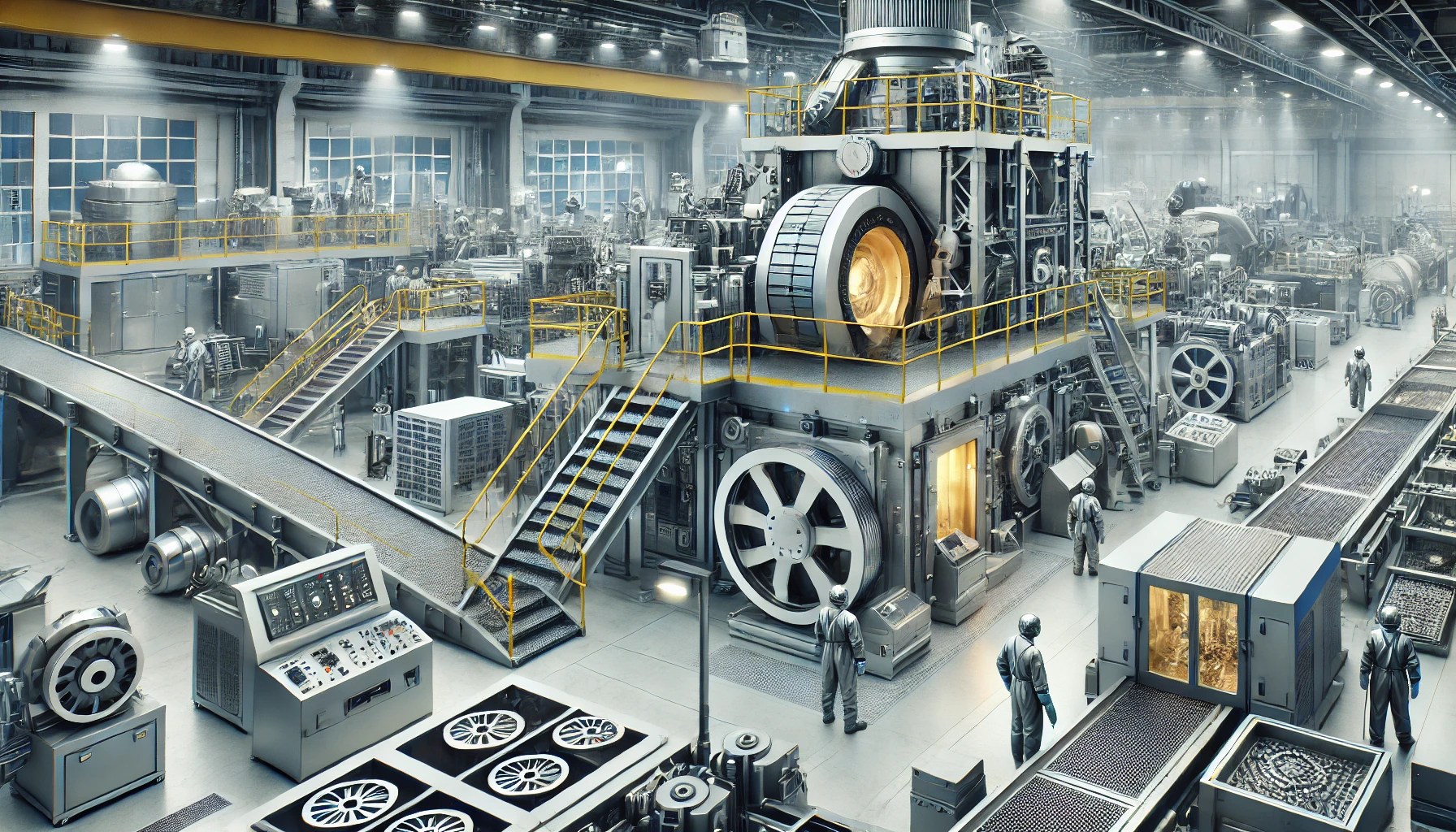

Advanced Production Equipment

Experience the cutting-edge manufacturing capabilities that set NBAEM apart as a leading magnetic material supplier. Our state-of-the-art equipment ensures precision, consistency, and superior quality in every product.

Precision Manufacturing Technology

NBAEM utilizes advanced production machinery designed specifically for magnetic material manufacturing. Our equipment combines innovative technology with precision engineering to deliver consistent, high-performance magnetic products.

- Automated production lines for consistent output

- Precision machining for exact specifications

- Advanced sintering furnaces for optimal material properties

Key Production Equipment

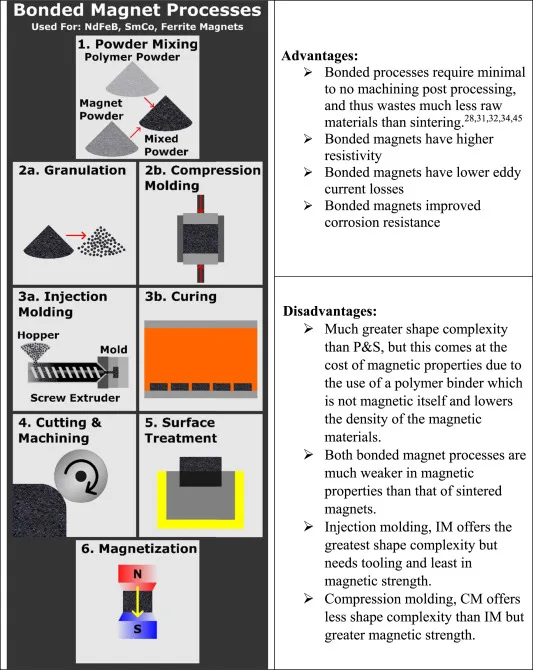

Powder Metallurgy Systems

Our advanced powder metallurgy equipment enables precise control over material composition and particle size distribution, ensuring consistent magnetic properties.

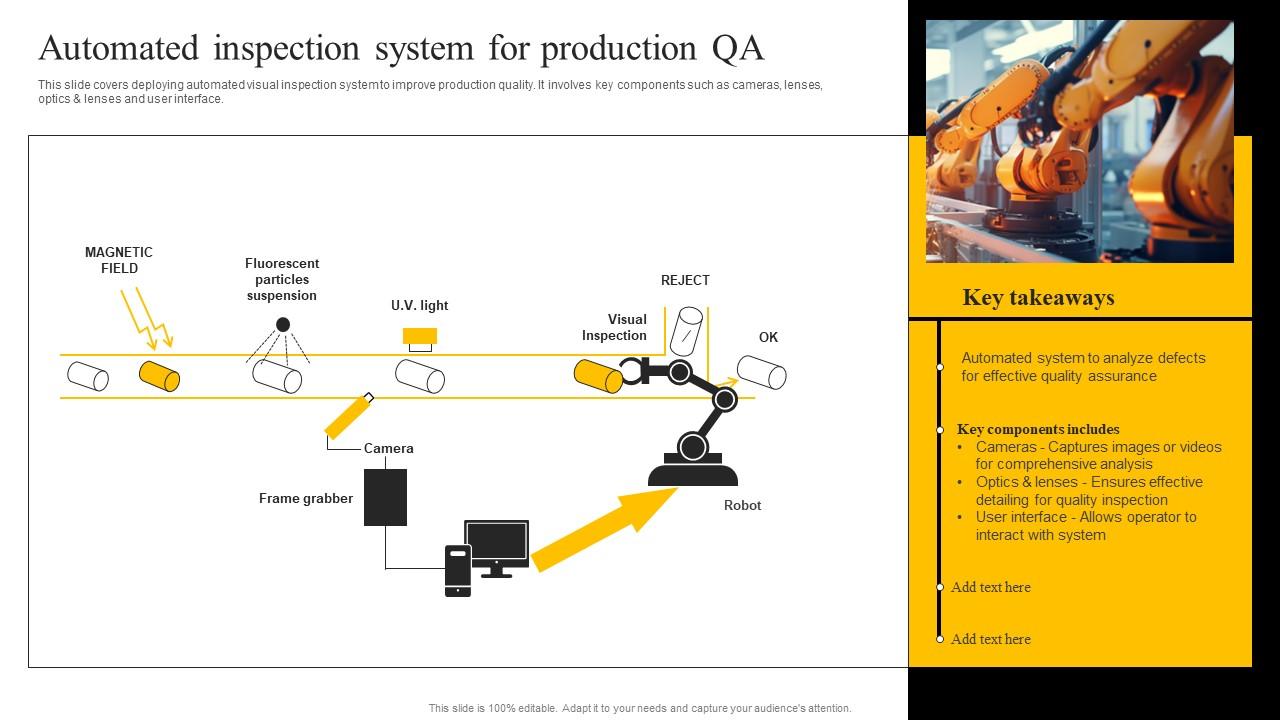

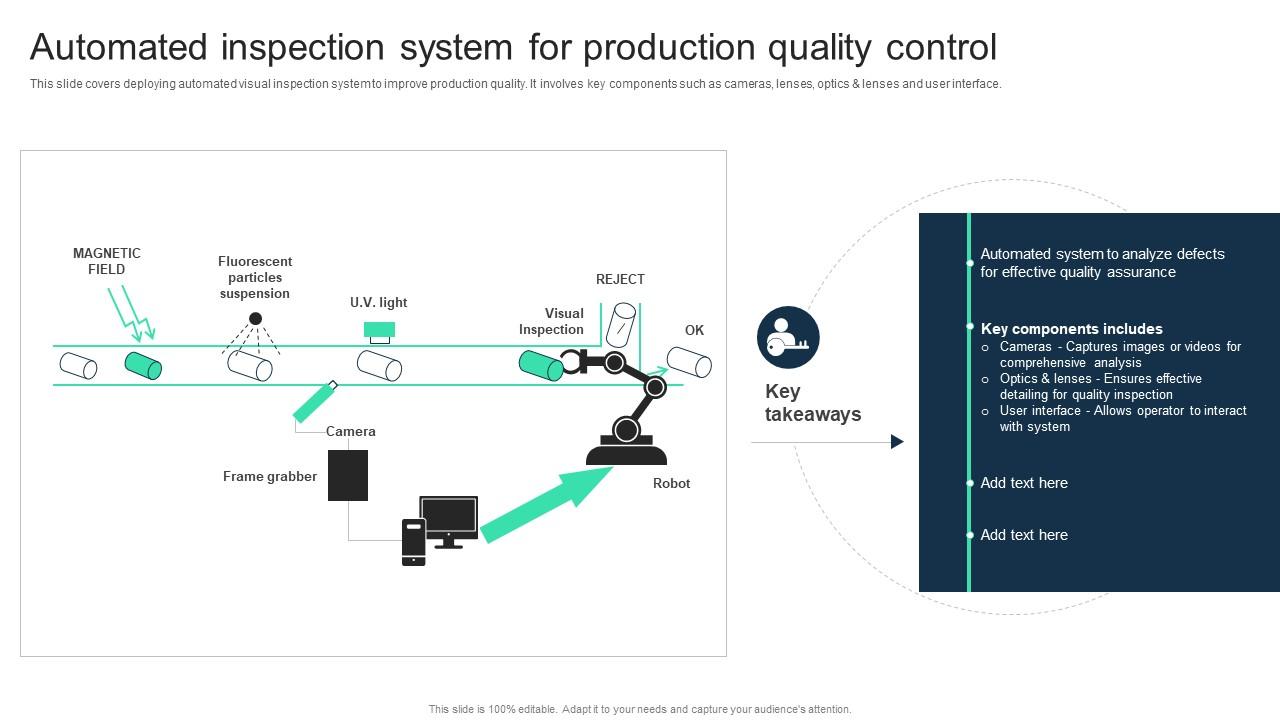

Quality Control Systems

Automated inspection equipment utilizing computer vision and AI to detect microscopic defects and ensure every magnet meets our rigorous quality standards.

Advanced Forming Technology

Cutting-edge forming equipment including precision presses for creating complex magnetic geometries with tight tolerances.

Enhancing Precision & Consistency

At NBAEM, we've invested in state-of-the-art equipment that dramatically improves the precision and consistency of our magnetic materials. Our manufacturing processes maintain tolerances within microns, ensuring perfect fit and optimal performance in your applications.

±0.02mm

Dimensional Tolerance

99.9%

Production Consistency

±2%

Magnetic Property Variance

24/7

Automated Monitoring

Experience Our Manufacturing Excellence

Discover how NBAEM's advanced production equipment can deliver superior magnetic materials for your specific applications.

Request Manufacturing SpecificationsCutting Edge Inspection & Testing Solutions

At NBAEM, we deploy advanced testing equipment and rigorous inspection processes to ensure magnetic material performance meets the highest industry standards.

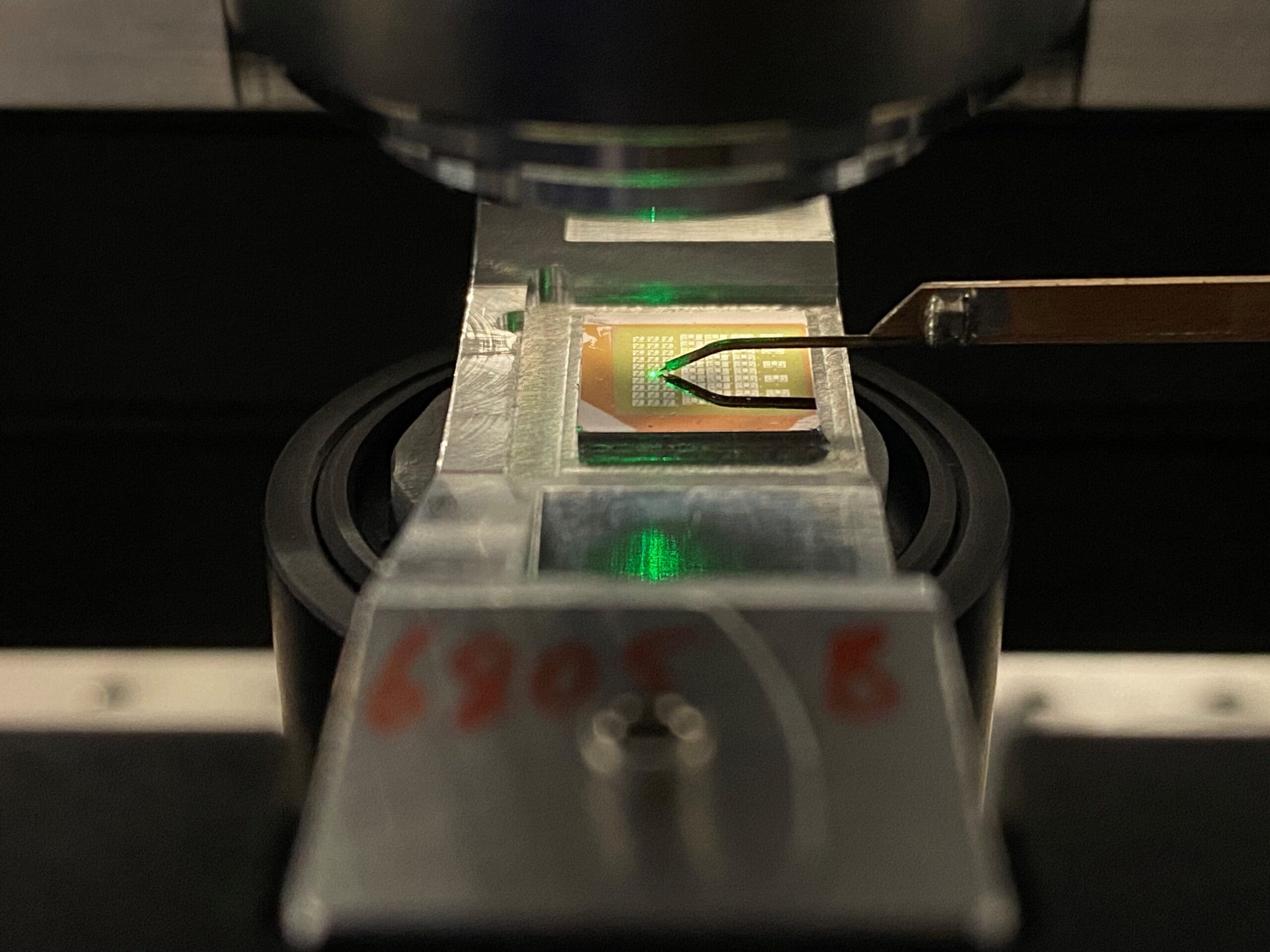

Advanced Testing Equipment

Our state-of-the-art testing devices provide precise measurements of magnetic properties, ensuring consistent quality across all our products.

- Magnetic Field Measurement Equipment

- Automatic Appearance and Size Inspection Equipment

- Precision Material Composition Analyzers

Our Inspection Process

Raw Material Testing

Chemical composition and purity verification before production begins

In-Process Inspection

Continuous monitoring during manufacturing to identify issues early

Final Performance Testing

Comprehensive magnetic property verification before shipment

NBAEM's Strict Quality Control Process

Our comprehensive quality control system ensures exceptional magnetic materials with minimal defects and maximum consistency across all product lines.

Raw Material Inspection

Every incoming material undergoes rigorous testing for chemical composition, physical properties, and purity to ensure it meets our stringent specifications.

Production Setup Verification

Our engineers calibrate and verify all equipment settings before each production run to ensure optimal manufacturing conditions.

In-Process Monitoring

Continuous monitoring and statistical process control throughout production identifies and corrects deviations before they become defects.

Sample Testing

Regular samples are collected during production for comprehensive testing of magnetic properties, dimensional accuracy, and surface quality.

Final Product Evaluation

Each finished batch undergoes multiple inspection points including magnetic field strength testing, coating verification, and visual inspection.

Documentation & Certification

Comprehensive quality records are maintained for each batch, with test results and certifications provided to customers for full traceability.

Quality Excellence Through Expertise & Innovation

At NBAEM, quality isn't just a process—it's our culture. Our dedicated team of QC engineers brings decades of combined experience to ensure consistent quality in every magnetic product we deliver.

Skilled QC Engineers

Our engineers undergo continuous training in the latest quality control methodologies and magnetic materials testing.

Continuous Improvement

We analyze quality data to identify trends and implement process improvements that minimize defects and enhance product consistency.

Advanced Testing Equipment

Our state-of-the-art laboratory features the latest in magnetic property testing and dimensional measurement technology.

Industry Certifications & Standards Compliance

At NBAEM, we maintain rigorous quality standards through international certifications, ensuring our magnetic materials meet the highest industry requirements.

ISO 9001

Our quality management system certification demonstrates our commitment to consistent quality and continuous improvement.

TS 16949

This automotive industry certification ensures our products meet strict requirements for automotive manufacturing.

RoHS Compliance

Restricts the use of hazardous substances, ensuring our products are environmentally responsible and safe.

REACH Compliance

European Union regulation for chemical safety that protects human health and the environment.

International Quality Standards

Our adherence to international standards reflects NBAEM's commitment to excellence in magnetic material manufacturing. Each certification represents our dedication to quality, safety, and environmental responsibility.

These certifications are regularly audited and renewed to ensure ongoing compliance with the latest standards and regulations in the industry.

Customer Benefits

- Regulatory compliance ensuring legal marketability in various regions

- Consistent product quality through standardized processes

- Reduced risk and enhanced supply chain reliability

- Environmental safety and sustainability compliance

Our Commitment to Excellence

Regular Audits

Continuous monitoring and improvement of our quality management systems

Staff Training

Ongoing education to ensure all team members understand compliance requirements

Documentation

Comprehensive records and documentation to support traceability and compliance

Quality Assurance for Custom Magnetic Solutions

At NBAEM, we maintain rigorous quality control standards for all custom magnetic materials, ensuring each solution meets your exact specifications and industry requirements.

Our Quality Assurance Approach

Every custom magnetic solution undergoes comprehensive testing to validate performance, durability, and compliance with international standards.

- ✓Material composition verification using advanced spectroscopy

- ✓Magnetic property testing under various environmental conditions

- ✓Dimensional accuracy verification to within 0.01mm tolerance

- ✓Accelerated aging tests to ensure long-term performance

Customized Testing Plans

Assessment

We analyze your specific requirements and develop a tailored testing protocol for your application.

Implementation

Our engineers perform rigorous testing using state-of-the-art equipment and methodologies.

Certification

Each product receives detailed documentation certifying compliance with all specifications.

Customer Satisfaction & Support

At NBAEM, we're committed to excellence not just in our magnetic materials, but in every customer interaction. Our comprehensive after-sales support ensures your complete satisfaction.

Quality Assurance

Every product undergoes rigorous testing before shipping. Our quality control team ensures each magnetic component meets industry standards and specifications.

Technical Expertise

Our support team includes engineers with extensive knowledge of magnetic materials, ready to assist with technical questions and application challenges.

Customized Solutions

We work closely with customers to develop tailored solutions for specific applications, with ongoing support throughout the product lifecycle.

Our Warranty Promise

- Standard 12-month warranty on all products

- Free replacement for manufacturing defects

- Extended warranty options available for high-volume orders

- Quality guarantee with detailed certification documentation

How to Reach Our Support Team

Technical Hotline

Direct access to our engineering team for urgent technical assistance

+86-18757483467Why Choose NBAEM for Your Magnetic Materials

Delivering premium quality magnetic materials with industry-leading reliability and precision.

Advanced Quality Control

Our rigorous testing protocols ensure every magnetic product meets the highest industry standards with precision and consistency.

Cutting-Edge Technology

We utilize state-of-the-art equipment and innovative manufacturing processes to deliver superior magnetic materials.

Material Expertise

With decades of experience in magnetic materials, our team of experts ensures optimal performance for your specific applications.

Quick Turnaround

Our efficient production lines and streamlined processes ensure timely delivery without compromising on quality.

Custom Solutions

We develop tailored magnetic materials to meet your specific requirements, ensuring optimal performance for your applications.

Rigorous Testing

Every batch undergoes comprehensive testing to guarantee consistent magnetic properties and exceptional performance.

Frequently Asked Questions

Common questions about NBAEM's quality control processes, certifications, and product performance standards.

NBAEM holds ISO 9001:2015 certification for quality management systems, ISO 14001 for environmental management, and is compliant with RoHS and REACH regulations. Our facilities are also certified for magnetic material production by industry-specific authorities.

We employ advanced testing equipment including gauss meters, pull testers, and environmental chambers to verify magnetic properties. Each batch undergoes thermal stability testing, corrosion resistance evaluation, and mechanical strength analysis to ensure long-term performance.

Our production line includes multiple inspection points with both automated and manual quality checks. We implement statistical process control (SPC), conduct material composition analysis, and perform dimensional verification at each stage of manufacturing to maintain consistent quality.

We employ precise raw material selection processes, controlled alloy formulation, and advanced magnetization equipment. Each batch is tested using hysteresis graph analyzers and flux density meters. Our proprietary quality tracking system ensures that every product meets specified magnetic performance parameters.

Each shipment includes a detailed quality certificate showing test results for magnetic properties, dimensional accuracy, and coating performance. Upon request, we can provide material composition analysis, extended performance data, and customized quality reports to meet specific industry requirements.

Comprehensive Quality Inspection

Our technicians perform detailed quality assessments on every production batch.

Advanced Testing Equipment

State-of-the-art measuring devices ensure precise magnetic property verification.

Have more questions about our quality control processes?

Contact Our Quality Team