Fundamentals of Magnetic Shielding

Magnetic interference poses a significant challenge in many industries, affecting the performance and reliability of sensitive electronic equipment and systems. This interference occurs when unwanted magnetic fields disrupt normal operation, causing signal distortion, data loss, or even hardware malfunction. Effective magnetic shielding is essential to protect devices from these adverse effects.

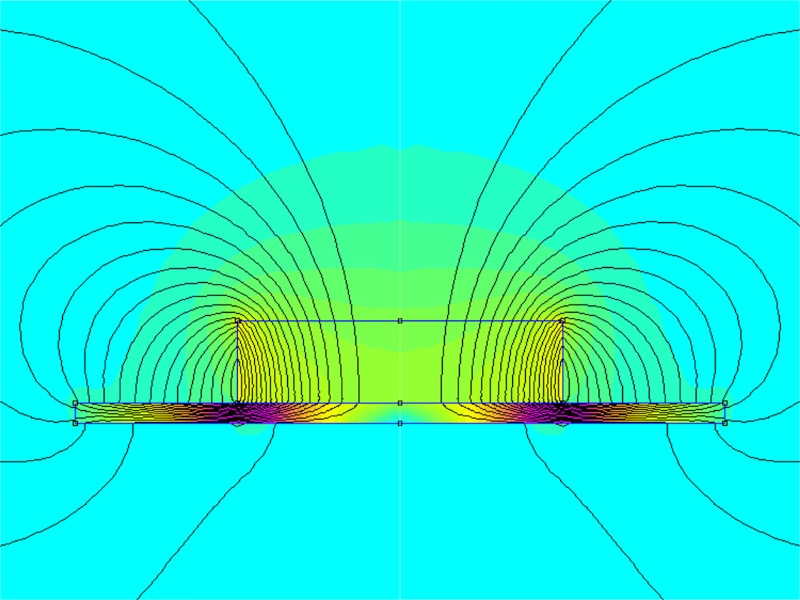

Magnetic shielding works by redirecting or absorbing magnetic field lines to reduce their impact within a protected zone. This is primarily achieved through materials with high magnetic permeability, which attract and channel magnetic flux away from sensitive areas. The basic principle involves creating a path of least resistance for magnetic fields, effectively attenuating the interference.

Two main types of magnetic fields require shielding consideration:

- AC (Alternating Current) Magnetic Fields: These fields constantly change direction and magnitude, making shielding more complex due to induced eddy currents and frequency-dependent behavior.

- DC (Direct Current) Magnetic Fields: These steady fields can saturate shielding materials, demanding robust solutions with high saturation points.

Each type presents unique challenges that influence material choice, shield design, and thickness. Understanding these fundamentals is crucial for developing effective shielding strategies tailored to specific applications. For further insight into magnetic properties impacting shielding effectiveness, visit NBAEM’s resource on magnetic permeability.

Traditional vs Advanced Magnetic Shielding Techniques

Traditional magnetic shielding has long relied on materials like mu-metal and other ferromagnetic alloys. These materials are known for their high permeability, effectively redirecting magnetic fields and protecting sensitive equipment. Mu-metal, in particular, has been a go-to choice for many industries due to its strong magnetic interference protection capabilities.

However, these conventional techniques come with clear limitations. They often involve bulky, heavy materials that can be tricky to shape or customize. Mu-metal is also expensive and requires precise heat treatment to maintain its shielding properties. Additionally, traditional shields may struggle with saturation under strong magnetic fields, limiting their effectiveness in high-demand environments.

This has led to a push toward advanced magnetic shielding solutions. Emerging materials like nanocrystalline alloys and magnetic composites offer better performance with less weight and greater flexibility. These advanced materials handle both AC and DC magnetic fields more efficiently, allowing for thinner, lighter, and more adaptable shields.

Advanced Magnetic Shielding Materials

When it comes to advanced magnetic shielding materials, the focus is on high-performance alloys and composites that outperform traditional options. Materials like nanocrystalline and amorphous metals offer excellent magnetic field attenuation due to their superior magnetic permeability and low coercivity. These materials create stronger, more efficient barriers against both AC and DC magnetic interference.

Magnetic composites and layered shielding materials are also gaining traction. By combining different substances in layers or blends, these composites balance flexibility, weight, and shielding effectiveness better than single-material solutions. This approach provides tailored protection for specific environments and applications.

NBAEM supplies a range of these advanced materials, backed by thorough quality control and certifications. Their products not only deliver high permeability and low magnetic saturation but are also optimized in thickness to maximize shielding without adding unnecessary bulk.

Key material properties influencing efficiency include:

- Permeability: Higher permeability means better magnetic flux absorption.

- Saturation: Materials with high saturation resist magnetic overload, maintaining effectiveness under strong fields.

- Thickness: Optimal thickness balances protection with weight and cost considerations.

Innovative Shielding Design Approaches

Modern magnetic shielding goes beyond just using thick layers of metal. Multilayer and graded shielding designs are now common, where different materials and thicknesses are stacked to target specific magnetic field strengths and frequencies. This layered approach improves overall attenuation without adding unnecessary bulk or weight.

Metamaterials and engineered structures are another breakthrough. These specially designed materials control magnetic fields in ways traditional shielding can’t, offering more precise and efficient protection. They can redirect or absorb stray fields, making them ideal for sensitive electronics and advanced medical devices.

Computational modeling and simulation play a big role in optimizing designs. Using advanced software, engineers can predict how magnetic fields interact with shielding materials and tweak designs before manufacturing. This saves time, cost, and improves performance by customizing shields for specific environments and applications.

Customization is key. Whether it’s aerospace avionics needing lightweight solutions or industrial equipment requiring durable shielding, tailored designs help meet unique requirements perfectly. This level of design flexibility is a major advantage in today’s magnetic interference protection strategies.

For more on magnetic shielding design principles, visit NBAEM’s detailed insights on magnetic permeability and soft magnetic materials.

Techniques for Enhancing Shielding Performance

Improving magnetic shielding performance goes beyond just choosing the right materials. Several techniques help boost efficiency, durability, and overall effectiveness.

Heat Treatment and Annealing

- These processes relieve internal stresses in magnetic alloys, which improves their permeability and magnetic softness.

- Proper annealing helps reduce magnetic hysteresis and increases shielding efficiency, especially for materials like nanocrystalline and advanced mu-metal alternatives.

Structural Treatments and Mechanical Processing

- Mechanical shaping, such as rolling or pressing, refines the microstructure of magnetic materials, enhancing their magnetic response.

- Stress relief treatments after mechanical work are essential to prevent weakening of magnetic properties.

Surface Coatings

- Protective coatings improve resistance to corrosion and wear, extending shield life in harsh environments.

- Coatings can also reduce eddy current losses, improving performance especially under AC magnetic fields.

- They ensure the shield maintains its integrity without adding significant weight or thickness.

Using these techniques together can optimize magnetic shielding for varied applications—whether in medical devices, aerospace, or consumer electronics—delivering reliable magnetic interference protection where it matters most.

Application Areas and Case Studies

Advanced magnetic shielding plays a crucial role across several industries where magnetic interference can cause serious issues. Here’s a quick look at key application areas:

Medical Devices and MRI Rooms

Magnetic interference can distort MRI images or affect sensitive diagnostic tools. Using advanced magnetic shielding materials, like nanocrystalline alloys or layered composites, helps ensure clearer images and precise diagnostics, protecting patients and equipment alike.

Aerospace and Defense

Avionics and navigation systems rely on stable magnetic environments for accuracy. Military and aerospace gear benefit from customized magnetic shielding solutions that reduce electromagnetic compatibility (EMC) problems, enhancing reliability in critical situations.

Consumer Electronics

Smartphones, wearables, and other personal devices require compact and efficient magnetic shielding to prevent interference that can affect performance and user experience. Advanced materials offer lightweight, durable protection that fits modern electronic designs.

Industrial Equipment

Heavy machinery like generators and transformers generate strong magnetic fields, which can disrupt nearby electronics or create safety hazards. Advanced shielding solutions mitigate these risks, improving operational safety and extending equipment life.

Each example highlights the need for tailored magnetic shielding that fits specific environments and device requirements, showing why advanced materials and designs are vital in today’s world.

Challenges and Future Trends

Balancing cost, weight, and performance remains a top challenge in advanced magnetic shielding. Customers want strong magnetic interference protection without bulk or high expense, especially in industries like aerospace and consumer electronics. Finding materials and designs that hit this sweet spot is crucial.

Environmental and safety regulations also shape how magnetic shielding materials are developed and used. Today’s solutions must comply with strict standards to avoid any harmful impacts or hazards during manufacturing and in use. This pushes manufacturers to innovate cleaner, safer materials.

Looking ahead, flexible magnetic shields and nanotechnology are gaining momentum. Flexible shields offer easier installation in tight or irregular spaces, perfect for wearables and medical devices. Nanocrystalline alloys and magnetic composites bring improved shielding efficiency at reduced thickness and weight.

Artificial intelligence and machine learning are making a real difference too. These technologies enable faster, smarter design optimization by simulating various materials and configurations before physical testing. This reduces development time and helps customize magnetic shielding solutions for specific needs.

By keeping an eye on these trends, we’re better equipped to meet the evolving demands of the U.S. market and beyond.

Why Choose NBAEM for Magnetic Shielding Solutions

NBAEM stands out as a top supplier for advanced magnetic shielding materials, trusted both in China and internationally. Here’s why:

Material Capabilities and Certifications

- Offers high-performance nanocrystalline alloys, amorphous metals, and advanced composites

- Strict quality control backed by ISO and industry certifications

- Consistent supply of top-grade materials designed for magnetic interference protection and EMC solutions

Customization and Manufacturing Excellence

- Tailors magnetic shielding products to meet specific design and environmental needs

- Expertise in multilayer, graded shielding and complex shapes

- Uses advanced manufacturing techniques for precision and reliability

Local Supply Chain Advantages

- Fast, dependable delivery for both domestic U.S. clients and international customers

- Streamlined logistics reduce lead times and costs

- Support for scalable orders, ideal for industries like medical devices, aerospace, and consumer electronics

Customer Success Stories and Partnerships

- Collaborates with leading companies on MRI shielding, avionics, and wearable tech

- Proven track record improving product performance and durability

- Ongoing partnerships to develop next-gen flexible and lightweight shielding solutions

| Key Benefits | Details |

|---|---|

| Advanced Materials | Nanocrystalline, amorphous alloys |

| Quality Assurance | ISO certification, rigorous testing |

| Custom Solutions | Tailored designs for any application |

| Supply Chain | Fast, reliable shipping worldwide |

| Industry Experience | Medical, aerospace, electronics |

Choosing NBAEM means getting cutting-edge magnetic shielding materials combined with expert support—perfect for U.S. businesses needing efficient, effective interference protection.

Leave A Comment