Overview of Common Magnetic Materials Used in Sensors

Magnetic materials are the heart of many sensor technologies, each type bringing unique properties that fit specific sensor applications. Understanding these materials helps in selecting the best option for performance, cost, and environment.

Ferrite Magnets

Ferrite magnets are ceramic compounds made mainly of iron oxide combined with barium or strontium. Known for their low cost and corrosion resistance, ferrites offer moderate magnetic strength and excellent temperature stability. They are widely used in consumer electronics, inductive sensors, and position sensing where affordability and durability matter.

Neodymium NdFeB Magnets

Neodymium magnets, based on neodymium-iron-boron alloys, are famous for their extremely high energy density. This high magnetic strength translates to smaller and more sensitive sensor components. However, NdFeB magnets are prone to corrosion and have lower thermal stability, often requiring coatings or special housings in tough environments.

Samarium Cobalt SmCo Magnets

Samarium cobalt magnets provide an excellent balance of high magnetic strength and outstanding thermal stability, withstanding temperatures beyond 250°C. Their corrosion resistance makes them ideal for aerospace, automotive, and industrial sensors operating in harsh or high-temperature environments. Though more expensive than NdFeB, SmCo magnets last longer under demanding conditions.

Alnico Magnets

Alnico magnets, composed mainly of aluminum, nickel, and cobalt, feature high temperature tolerance and stable magnetization over a wide temperature range. While their magnetic strength is lower than rare earth magnets, they excel in applications requiring steady magnetism without degradation across temperature swings, such as certain speed and position sensors.

Amorphous and Nanocrystalline Magnetic Materials

Emerging magnetic materials like amorphous and nanocrystalline alloys are gaining interest due to their superior magnetic softness, low coercivity, and high permeability. These materials are ideal for precision sensing where low noise and fast response are critical. Their unique microstructures also allow better adaptability for miniaturized and flexible sensor designs.

Each magnetic material offers a distinct set of advantages suited for various sensor types. Selecting the right magnet depends on balancing magnetic properties, operating environment, size constraints, and cost. For a detailed understanding of magnetic properties, NBAEM offers extensive insights into magnetic anisotropy and sensor magnet materials tailored to your needs.

Key Magnetic Properties Critical for Sensor Applications

When choosing magnetic materials for sensor use, certain properties really stand out because they directly impact how well the sensor performs and lasts.

Coercivity

This is the material’s resistance to losing its magnetism when exposed to external magnetic fields or temperature changes. High coercivity means your sensor stays accurate over time, avoiding signal drift or failure. It’s essential for reliable sensor operation, especially in tough environments.

Remanence and Magnetic Flux Density

Remanence is the remaining magnetism after removing an external magnetic field. It determines how strong the sensor’s magnetic signal is. Higher remanence and magnetic flux density mean better sensitivity, allowing the sensor to pick up smaller changes in magnetic fields. This is key for precision in Hall effect and magnetoresistive sensors.

Curie Temperature and Thermal Stability

The Curie temperature marks the point at which a magnet loses its magnetic properties due to heat. Materials with a high Curie temperature maintain performance in high-temperature setups, common in automotive or industrial sensors. Thermal stability ensures consistent readings over temperature swings without material degradation.

Magnetic Permeability and Hysteresis Losses

Magnetic permeability defines how easily a material channels magnetic fields. High permeability helps sensors respond faster and more accurately. Low hysteresis loss means less energy wasted during magnetic cycling, which is vital for sensors that operate continuously or at high speeds.

Corrosion Resistance and Environmental Durability

Sensors often face harsh environments—humidity, chemicals, vibration, and wear. Magnetic materials with good corrosion resistance hold up longer, reducing sensor failure and maintenance needs. Choosing durable materials keeps your sensors working reliably outdoors or in industrial settings.

Understanding these properties helps you pick the right magnetic materials that balance sensitivity, stability, and durability for your sensor applications in the U.S. market.

Comparative Analysis Performance Cost and Application Suitability

When choosing magnetic materials for sensor applications, balancing performance, cost, and suitability is key. Different magnets shine in various sensor types, so understanding these factors helps in picking the right fit.

Performance Metrics Comparison

| Magnetic Material | Energy Density | Coercivity | Thermal Stability | Corrosion Resistance | Suitability for Miniaturization |

|---|---|---|---|---|---|

| Neodymium (NdFeB) | Very High | Medium | Moderate | Low | Excellent |

| Samarium Cobalt (SmCo) | High | High | Excellent | Excellent | Moderate |

| Ferrite | Low | Medium | Good | Very Good | Limited |

| Alnico | Moderate | Low | Very High | Moderate | Poor |

| Amorphous/Nanocrystalline | Variable | High | High | Good | Good |

Cost Effectiveness for Sensor Types

- Neodymium magnets offer top performance at a mid-range price. Great for high-sensitivity sensors needing compact size.

- Samarium Cobalt costs more but excels in extreme temperatures and corrosion—ideal for aerospace or automotive sensors.

- Ferrite magnets are budget-friendly and widely used in everyday consumer electronics, but they don’t support miniaturization well.

- Alnico magnets are pricier due to manufacturing complexity and their lower coercivity limits their use in modern sensor designs.

- Emerging amorphous and nanocrystalline materials bring exciting performance but currently at a premium price.

Suitability by Sensor Application

- Hall Effect Sensors: Neodymium and amorphous materials suit these well because of size and sensitivity demands.

- Magnetoresistive Sensors: Benefit from high coercivity materials like SmCo for stability and performance.

- Inductive Sensors: Ferrite magnets work fine with low-cost and moderate performance needs.

- Position and Speed Sensors: Require magnets with consistent remanence and thermal stability; SmCo and NdFeB are common choices.

Impact of Size and Miniaturization

Compact sensors demand magnets with high energy density and thermal stability. Neodymium magnets lead here due to their strength and small size. In contrast, ferrites struggle as their lower energy density means bigger magnets for the same performance. SmCo fits well when thermal and corrosion resistance are crucial, even if size is slightly larger. Emerging materials also show promise for next-gen miniaturized sensors, blending performance with durability.

Choosing the right magnetic material depends on how these factors line up with your sensor’s application and budget.

Environmental and Operational Factors Affecting Material Selection

Choosing the right magnetic material for sensors means looking beyond just performance specs. Environmental and operational conditions play a big role in how a magnet will hold up over time.

High Temperature and Harsh Environments

Sensors used in industrial settings or automotive engines often face high temps and tough environments. Materials like Samarium Cobalt (SmCo) excel here because they resist heat and corrosion better than Neodymium (NdFeB), which can lose magnetism when it gets too hot. Ferrite magnets also handle moderate heat well but aren’t great for extreme conditions.

Mechanical Stress and Vibration

In applications like aerospace or heavy machinery, sensors deal with constant vibration and mechanical shocks. Magnetic materials need to withstand this without cracking or degrading performance. Alnico and SmCo magnets are known for their toughness here, while brittle magnets like NdFeB require careful design to avoid damage.

Longevity and Magnet Aging

Magnets weaken over time, especially under harsh conditions. Understanding aging effects helps predict sensor life. Materials with high coercivity, such as SmCo, tend to maintain their magnetization longer. NdFeB magnets may lose strength faster if exposed to moisture or heat, so proper coating and maintenance are critical.

When selecting magnetic materials for sensors in the U.S. market, keep in mind the environment and expected stress levels. Matching the magnet’s durability and stability to your sensor’s use case ensures reliability and reduces replacement costs.

Case Studies Successful Sensor Applications Using Different Magnetic Materials

Let’s look at how different magnetic materials perform in real-world sensor applications across industries, highlighting why their unique traits matter.

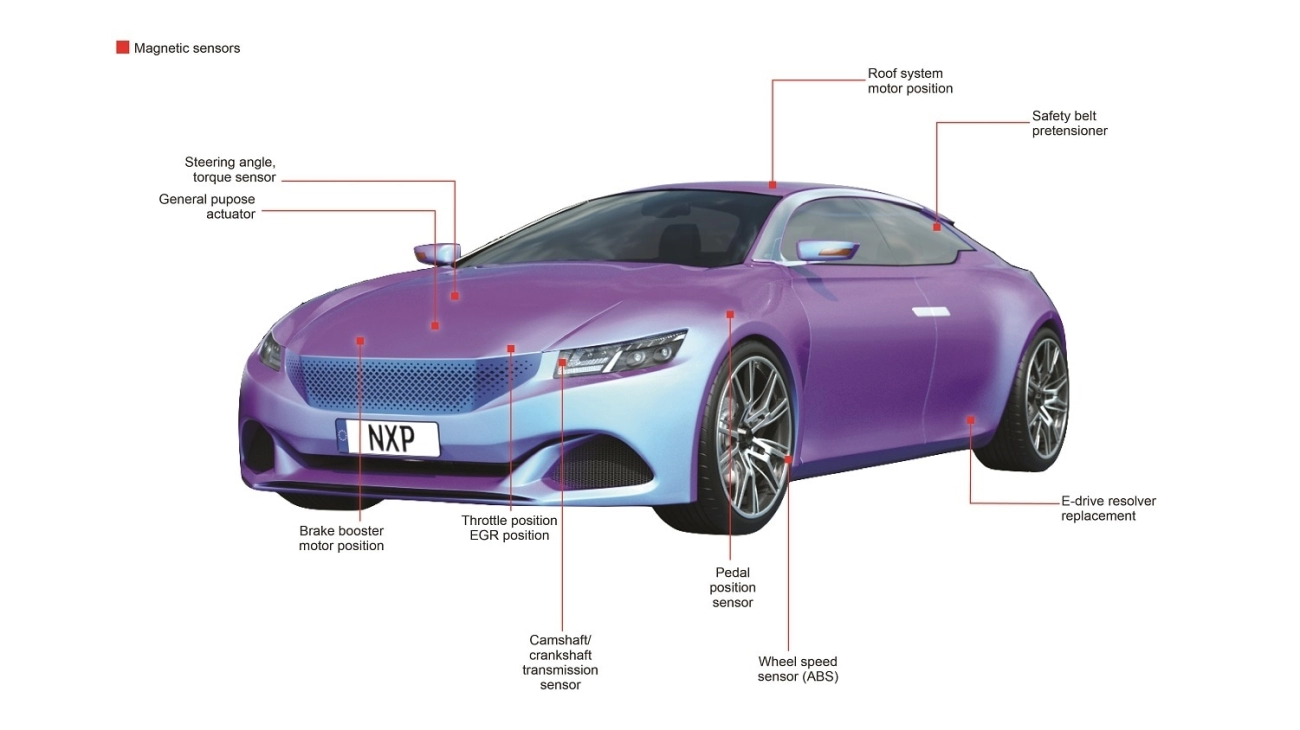

NdFeB Magnets in Automotive Sensors

Neodymium Iron Boron (NdFeB) magnets are the go-to for many automotive sensors because of their high energy density and strong magnetic fields. They help in:

- Precise position sensing (e.g., camshaft and crankshaft sensors)

- Speed detection (wheel speed sensors)

- Reliable operation even in compact spaces due to their size advantage

Their strong magnetization improves sensor sensitivity and overall vehicle performance.

SmCo Magnets in Aerospace Sensors

Samarium Cobalt (SmCo) magnets shine in aerospace thanks to their:

- Excellent thermal stability at high altitudes and extreme temperature swings

- Superior corrosion resistance, making them durable under harsh environmental conditions

- Stability over time, ensuring precise sensor readings critical for flight safety and control systems

They’re often used in navigation sensors and actuator mechanisms where reliability is non-negotiable.

Ferrite Magnets in Consumer Electronics Sensors

Ferrite magnets, though lower in energy density, are a solid choice for consumer electronics due to their:

- Cost-effectiveness and wide availability

- Good resistance to corrosion and demagnetization in everyday use

- Application in Hall effect sensors and small inductive sensors like those in smartphones and home appliances

They balance performance and affordability for mass-market sensor solutions.

NBAEM’s Magnetic Material Solutions for Sensor Clients

NBAEM, a Chinese magnetic material supplier, customizes magnetic materials tailored to diverse sensor needs:

- Offering NdFeB magnets optimized for automotive and industrial sensor applications

- Providing SmCo magnets designed to withstand aerospace-level thermal and corrosion challenges

- Supplying ferrite and emerging nanocrystalline materials for cost-sensitive and precision electronic sensors

Their R&D focus ensures materials meet US market standards for sensor magnet performance and durability.

| Magnetic Material | Typical Applications | Key Advantages | NBAEM Offering Highlights |

|---|---|---|---|

| NdFeB | Automotive sensors | High energy density, compact | Custom grades for sensitive sensors |

| SmCo | Aerospace sensors | Thermal stability, corrosion resistance | High-temp stable formulations |

| Ferrite | Consumer electronics | Cost-effective, corrosion resistant | Standard and customized options |

| Nanocrystalline | Emerging sensors | High sensitivity, low losses | Innovative solutions for precision |

This quick overview shows why choosing the right magnetic material matters in sensor applications—and how NBAEM supports these US market demands with reliable options.

Future Trends and Innovations in Magnetic Materials for Sensors

Material science is pushing magnetic sensors to new levels. Advances are focusing on improving sensitivity, stability, and miniaturization—key for smart devices and the growing IoT market in the U.S. Sensors now benefit from magnetic materials that adapt to changing conditions, making them smarter and more reliable.

Smart magnetic materials are being developed to interact directly with IoT sensors, enabling real-time adjustments based on environmental changes or device needs. This integration improves accuracy and reduces power consumption, which is a big deal for portable and wireless sensors.

Another major trend is sustainability. More companies are working on recyclable magnetic materials to reduce waste and environmental impact, a priority for many American manufacturers. These eco-friendly magnets don’t just help sensor performance but also align with stricter environmental regulations and consumer expectations in the U.S.

Together, these innovations are shaping the future of sensor magnet performance, offering more efficient, durable, and greener options for a wide range of applications—from automotive to industrial and consumer electronics.

[…] detailed applications related to sensor materials and magnetic interference, check out NBAEM’s magnetic materials for sensor applications. This helps engineers and manufacturers make informed choices tailored to their specific project […]

[…] NBAEM is leading the way by supplying eco-friendly, high-purity magnetic alloys that make these sensors possible. Their custom magnetic materials support reliable, efficient sensors for smart appliances. For more details on NBAEM’s magnetic materials for sensor applications, check out magnetic materials for sensor applications. […]