How to Make a Magnet Stronger

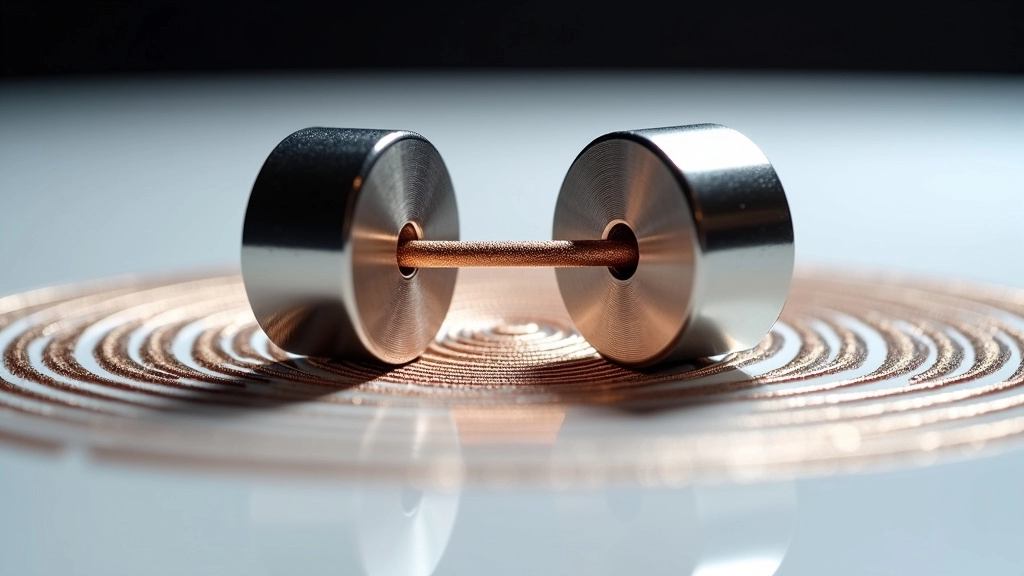

Have you ever wondered what makes some magnets stronger than others? The strength of a magnet depends on several key factors like the magnetic field, the material type, the size, and the shape of the magnet.

What Determines Magnet Strength

- Material Type: Different materials create different magnetic strengths. For example, neodymium magnets are among the strongest permanent magnets, far stronger than ceramic or alnico magnets.

- Size: Larger magnets generally have a stronger magnetic field because they have more magnetic material.

- Shape: The shape affects how the magnetic field lines spread; some shapes help focus the field better.

- Magnetic Field: The strength you feel depends on how well the magnetic domains inside the material align.

Common Types of Magnets and Strength Levels

- Neodymium magnets – Very strong, widely used in industry and electronics.

- Ceramic magnets – Moderate strength, affordable and common in household items.

- Alnico magnets – Older type, stable but not as strong as neodymium.

How Magnetism Works

At the core, magnetism comes from tiny regions called magnetic domains. These domains are like miniature magnets inside the material. When they align in the same direction, the magnet is strong. Poor alignment means a weak magnet.

Why Some Magnets Lose Strength Over Time

Magnets can lose strength when:

- Exposed to heat that disrupts domain alignment

- Physical shocks or impacts cause misalignment

- Strong opposing magnetic fields reduce their magnetism

Understanding these basics helps you know why some magnets feel weak and what you can do to improve them.

Common Methods to Make a Magnet Stronger

If you want to increase magnetic strength, there are practical ways to boost your magnet’s power without buying a new one.

Re-magnetizing a magnet

Over time, magnets can lose some strength, but you can fix this by re-magnetizing. Common methods include:

- Stroking your magnet with a stronger magnet several times to realign its magnetic domains.

- Using an electromagnet to apply a controlled magnetic field and restore or enhance magnetism.

Increasing magnet size or stacking magnets

Adding size can naturally increase strength, but if you don’t want a bigger magnet, try stacking multiple magnets together. Stacking builds a stronger combined magnetic field by aligning their poles, creating a more powerful pull.

Using magnetic circuits

You can concentrate magnetic flux by incorporating iron or steel cores around or inside the magnet. These materials guide the magnetic field lines, intensifying the overall magnetic force where you need it most.

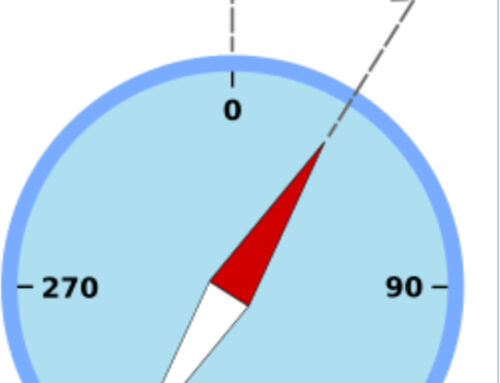

Proper magnet orientation and placement

Position matters—placing magnets so their poles align properly ensures maximum magnetic pull. In devices or setups, optimizing how magnets face each other can make a big difference in their effective strength.

Cooling magnets to boost strength

Lower temperatures can increase magnet strength by reducing thermal vibrations that disrupt magnetic domains. Just be mindful—extreme cold is better for some magnets like neodymium, but others may not respond well to cooling. Always check the magnet’s material limits.

These common methods help you get more from your magnets whether for DIY projects, industrial use, or hobby applications. For more about magnetic materials and types, check out our detailed guide on what are magnets made of.

Advanced Techniques and Materials Used by NBAEM

At NBAEM, we use specialized magnetic alloys designed to boost magnet strength beyond standard levels. These advanced materials help increase magnetic flux and overall performance.

We also apply heat treatment and annealing processes, which improve magnetic properties by refining the internal structure of the magnet. This step is key to achieving stronger, more reliable magnets.

Custom magnet shapes are another way we maximize magnetic field concentration. By shaping magnets precisely, we can focus their magnetic force where it’s needed most, enhancing effective strength without increasing size.

Finally, NBAEM adds protective coatings to our magnets. These layers guard against corrosion and physical wear, helping maintain strength and durability over time. This careful protection is especially important for magnets used in tough environments.

By combining these advanced materials and techniques, NBAEM delivers magnets that meet high standards for strength and long-lasting performance.

Practical Tips and Precautions

Handling strong magnets safely is key to avoiding injury and damage. Always keep magnets away from electronics, credit cards, and pacemakers. When dealing with large magnets, use gloves and keep fingers clear to prevent pinching accidents. Store magnets separately or with spacers to avoid sudden snapping together.

To avoid demagnetization, protect magnets from shocks, drops, and strong vibrations. High temperatures can weaken magnetic strength, so keep magnets away from heat sources above their recommended limits. Also, avoid exposing magnets to strong electrical currents that can disrupt magnetic domain alignment.

To extend your magnet’s lifespan and maintain its strength:

- Store magnets in a cool, dry place

- Keep magnets away from direct sunlight and moisture

- Use protective coatings if possible to prevent corrosion

- Re-magnetize weak magnets if needed using proper magnetizing techniques

Following these simple care tips will help keep your magnets powerful and reliable for longer.

Frequently Asked Questions FAQs

Can all magnets be made stronger?

Not all magnets can be easily strengthened. Permanent magnets like neodymium and alnico respond well to re-magnetizing and certain treatments, but ceramic magnets have limits. The magnet’s material type and condition play a big role in whether strength can be improved.

Is increasing magnet size the only way to increase strength?

No, increasing size helps, but it’s not the only method. Stacking magnets, re-magnetizing with a stronger magnetic field, adding iron cores to focus magnetic flux, and optimizing magnet orientation are effective ways to boost strength without making a bigger magnet.

How does temperature affect a magnet’s strength?

Temperature impacts magnetic strength significantly. Cooling a magnet generally increases its strength, while overheating can cause permanent loss by disturbing magnetic domains. Each magnet type has a specific temperature range where it works best.

What are the differences between temporary and permanent methods to strengthen magnets?

Temporary methods, like using external electromagnets or stacking, boost strength only while applied. Permanent methods involve changing the magnet’s internal structure through re-magnetizing, heat treatments, or using special alloys, resulting in lasting improvements.

How does NBAEM ensure the highest quality in their magnetic products?

NBAEM uses advanced materials like neodymium alloys, applies precise heat treatments, and employs strict testing to guarantee strong, consistent magnets. Their expertise means customized designs with maximum magnetic performance suited for U.S. customers who need reliable, durable magnets.

Why Choose NBAEM for Your Magnetic Material Needs

NBAEM brings years of expertise in magnetic materials, serving businesses across the U.S. with top-quality magnets designed for strength and durability. Whether you need neodymium magnets or custom magnetic solutions, NBAEM delivers reliable, high-performance products made to fit your exact specifications.

What Sets NBAEM Apart

- Quality Assurance: Strict quality control ensures consistent magnetic strength and longevity.

- Customization: Tailored magnet sizes, shapes, and strengths to meet unique project needs.

- Technical Support: Expert guidance throughout your order, from product selection to installation advice.

- Competitive Pricing: Cost-effective solutions without sacrificing quality.

- Fast Shipping: Ready to support local U.S. businesses with timely deliveries.

Client Success Stories

- A U.S.-based manufacturer improved their magnetic assembly reliability by switching to NBAEM’s specially heat-treated neodymium magnets.

- An electronics company reduced system failures using NBAEM’s custom-shaped ceramic magnets designed for tighter magnetic field concentration.

Get in Touch

For custom magnet orders or bulk supplies that meet your exact magnetic strength needs, contact NBAEM directly today. Experience increased magnetic performance backed by trusted expertise and tailored support.

[…] By following these tips, you can create custom potted magnets tailored to your project’s demands that perform reliably in various settings. For more in-depth guidance on enhancing magnet strength, check out our detailed guide on how to make a magnet stronger. […]