If you’re exploring what SmCo magnets are used for, you’re tapping into a world of high-performance magnetic technology trusted across advanced industries. Samarium Cobalt (SmCo) magnets stand out for their exceptional strength, thermal stability, and resistance to corrosion—qualities that make them a top choice where reliability under extreme conditions matters most. Whether you’re an engineer, a technical buyer, or just curious about their applications, understanding where and why SmCo magnets excel will help you make smarter decisions for your projects. Let’s dive into the key uses and advantages of these powerful magnets and see why NBAEM is your go-to expert and supplier for premium SmCo magnetic materials.

What are SmCo Magnets

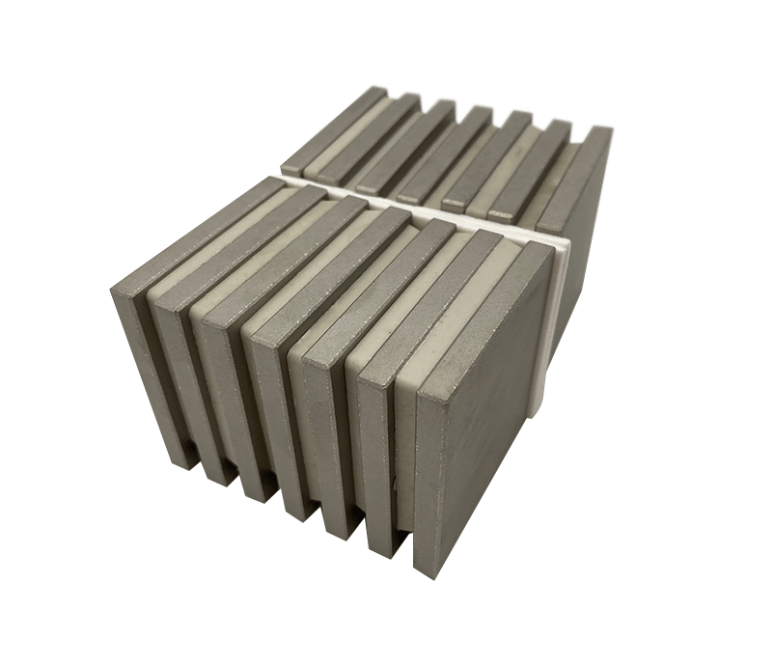

Samarium Cobalt (SmCo) magnets are a type of rare-earth magnet known for their exceptional magnetic strength and durability. They are primarily composed of samarium, cobalt, and small amounts of other elements to enhance performance. SmCo magnets come in two main types: SmCo5 and SmCo17.

SmCo5 magnets have a simpler composition and offer strong magnetic performance with excellent resistance to high temperatures. SmCo17 magnets contain a higher cobalt content and additional rare-earth elements, providing even greater magnetic strength and improved temperature stability.

Key properties of SmCo magnets include:

- High magnetic strength suitable for demanding applications

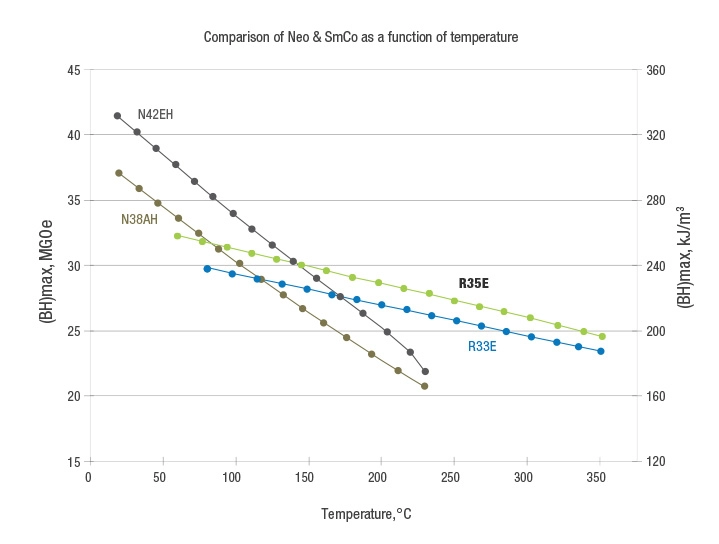

- Outstanding temperature stability, capable of operating up to 350°C

- Superior resistance to corrosion and oxidation, often eliminating the need for protective coatings

These characteristics make SmCo magnets ideal for use in environments where strong, reliable magnets are required under extreme conditions.

Key Advantages of Using SmCo Magnets

SmCo magnets stand out for their excellent thermal stability, working reliably at temperatures up to 350°C. This makes them a top choice for applications where heat resistance is critical. They also offer superior corrosion and oxidation resistance, often eliminating the need for extra coatings or treatments. Their magnetic strength is strong and consistent, providing dependable performance over time without significant loss of power. Plus, SmCo magnets resist demagnetization, ensuring long-lasting reliability even in demanding environments.

Main Industrial Applications of SmCo Magnets

SmCo magnets are widely used across various industries because of their strength, durability, and resistance to extreme conditions.

- Aerospace and Defense: Used in guidance systems, actuators, and sensors where reliability in harsh environments and extreme temperatures is critical.

- Automotive Industry: Ideal for electric motors, especially in hybrid and electric vehicles, handling high temperatures without losing magnetic strength. They’re also common in sensors and actuators that operate reliably in tough conditions.

- Medical Devices: Essential in MRI machines, magnetic separators, and diagnostic equipment, where safety, stability, and resistance to demagnetization are key.

- Electronics and Telecommunications: Found in micro motors, speakers, and magnetic couplings, benefiting from SmCo magnets’ stable performance in high-frequency and high-temperature applications.

- Renewable Energy Sector: Used in wind turbine generators that require magnets capable of withstanding high temperatures and long-term durability.

- Industrial Equipment and Robotics: Critical for precision motors, sensors, and actuators in robotic arms and automation machinery where consistent magnetic performance matters.

- Consumer Products: Popular in high-end audio devices, magnetic latches, and holding systems for their strong, corrosion-resistant magnetic force.

For more insights on high-performance magnetic materials and rare earth magnet types, check out our Guide to Rare Earth Magnets and learn about their uses in electric motors like Magnets in Coreless Motors.

Comparison with Other Magnet Types

When comparing SmCo magnets to Neodymium (NdFeB) magnets, a few key differences stand out, especially for buyers in the United States looking for reliable, high-performance magnets.

| Feature | SmCo Magnets | NdFeB Magnets |

|---|---|---|

| Temperature Tolerance | Up to 350°C, excellent stability | Typically up to 150°C, lower stability |

| Corrosion Resistance | Highly corrosion resistant, often no coating needed | Prone to corrosion, usually requires protective coating |

| Magnetic Strength | Strong, but slightly less powerful | Very strong, highest magnetic strength |

| Cost | Generally more expensive | More affordable |

| Resistance to Demagnetization | High, maintains performance over time | Moderate, can lose strength under high heat or shock |

When SmCo Magnets Outperform NdFeB

- High temperature environments: SmCo magnets maintain their magnetic force in extreme heat, making them ideal for aerospace, automotive under-hood, and industrial uses.

- Harsh, corrosive settings: Their natural corrosion resistance means less maintenance and longer life without coatings.

- Long-term reliability: SmCo resists demagnetization better, ensuring steady performance over many years.

When NdFeB Magnets Are a Better Fit

- Budget-sensitive projects: NdFeB magnets cost less, making them a common choice for consumer products and general electronics.

- Where maximum magnetic strength is needed: They offer the highest magnetic pull for size, important in compact designs.

- Room temperature applications: For uses where heat and corrosion aren’t critical concerns, NdFeB works well.

Choosing between SmCo and NdFeB magnets boils down to your specific application needs — if your project demands heat resistance, corrosion protection, or long-term stability, SmCo magnets are the better option. For high magnetic strength at a lower price and less demanding conditions, NdFeB magnets are popular.

If you’re unsure which magnet type fits your needs best, reach out to a trusted US supplier who can provide custom advice and solutions tailored to your industry.

Why Choose NBAEM for Your SmCo Magnet Needs

When it comes to sourcing high-quality SmCo magnets, NBAEM stands out thanks to its deep expertise and strong manufacturing capabilities. We offer a reliable supply of SmCo magnets tailored to meet the demanding needs of U.S. customers, especially those in industrial and tech sectors.

NBAEM’s Strengths

- Expertise: Years of experience in producing SmCo magnets ensures consistent high performance and quality.

- Advanced Manufacturing: State-of-the-art production lines that handle SmCo5 and SmCo17 magnets with precision.

- Customization: Flexible options for size, shape, and magnetic strength to fit your exact application.

- Quality Assurance: Rigorous testing for magnetic properties, temperature resistance, and corrosion durability.

- Sustainable Supply Chain: Committed to ethical sourcing and steady material availability to support your long-term projects.

By choosing NBAEM, you get more than just a magnet—you get a partner focused on reliability, performance, and meeting your specific SmCo magnet needs.

How to Select the Right SmCo Magnet for Your Application

Choosing the right SmCo magnet depends on a few key factors that match your specific needs:

- Magnetic Strength: Understand the required magnetic force for your device. SmCo magnets come in different grades, so pick one that delivers the strength needed without over-specifying, which can add unnecessary cost.

- Thermal Requirements: SmCo magnets are known for excellent heat resistance, but you still need to check your operating temperature range. Some applications might need magnets that can handle up to 350°C, so choose the right SmCo type—like SmCo5 or SmCo17—based on thermal stability.

- Shape and Size: Your product’s design affects magnet shape and size. Whether you need rings, blocks, discs, or custom shapes, ensure the magnet fits physically and performs well in your layout.

- Environmental Exposure: SmCo magnets naturally resist corrosion, but if your application involves aggressive chemicals or extreme humidity, confirm whether additional coatings or treatments are needed.

When working with suppliers like NBAEM, make use of their expertise and customization options. They can help tailor magnet properties, shapes, and finishes to meet both performance and budget goals. Clear communication about your application’s specifics—like temperature, mechanical stress, and environmental conditions—helps achieve the best match.

For more detailed insight on magnet types and their effects under heat, consider exploring types of magnets.

Selecting the right SmCo magnet with the right supplier ensures reliable performance and durability in your end product.

Leave A Comment