What Makes Cylindrical Magnets So Powerful Core Properties Explained

Cylindrical Magnets

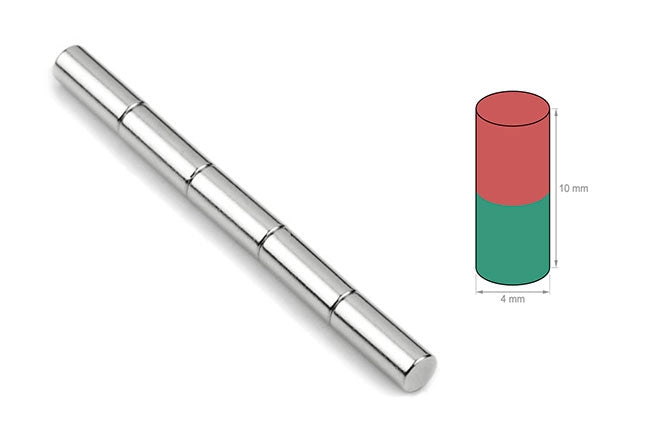

Cylindrical magnets, often called rod magnets, are shaped like small, solid cylinders—think of a short, thick rod. This simple yet effective design gives them a unique magnetic profile. Their length and diameter can vary, allowing for customization that suits many different strength and application needs.

The real power behind these magnets lies in their material. Most high-performance cylindrical magnets are made from neodymium, a rare-earth metal known for exceptional magnetic strength. Neodymium magnet grades range from N35 up to N52, with higher numbers indicating stronger magnetic force and better overall performance. For example:

- N35: Strong but more affordable, ideal for general use.

- N42: Offers a good balance of power and cost.

- N52: The strongest commonly available grade, used where maximum pull force is essential.

Compared to older materials like ferrite (ceramic) magnets or Alnico magnets, neodymium cylinders provide a vastly greater magnetic field with less bulk. Ferrite magnets, for instance, offer decent strength at low cost but are brittle and weaker, while Alnico magnets provide good temperature stability but lack the pull force of neodymium.

Key metrics that define cylindrical magnet strength include:

- Pull force: The amount of weight the magnet can hold when directly in contact with a steel surface.

- Surface field strength: Measured in gauss or tesla, indicating magnetic intensity at the magnet’s surface.

- Magnetic reach: How far the magnetic effect extends from the magnet.

Here’s a simplified comparison of pull forces and surface field strengths across common neodymium grades for a 1/2″ diameter by 1″ length cylinder:

| Grade | Pull Force (lbs) | Surface Field (kG) | Magnetic Reach (inches) |

|---|---|---|---|

| N35 | 6.5 | 9.8 | 0.8 |

| N42 | 8.2 | 11.5 | 1.0 |

| N52 | 10.5 | 14.2 | 1.2 |

At NBAEM, we source only premium neodymium materials to maintain consistent quality and performance. This ensures every cylindrical magnet meets strict industrial standards, providing reliability in critical applications. Our supply chain is carefully managed to offer traceability, certification, and a steady stock of the highest grade rare earth cylinder magnets, making NBAEM a trusted partner for your projects.

Understanding what makes cylindrical magnets so powerful starts with recognizing how their standardized shape and top-grade materials combine to deliver exceptional pull force and magnetic reach—traits that set them apart in the world of magnets.

Axial vs Diametric Magnetization Which Boosts Strength for Your Needs

Cylindrical magnets can be magnetized in two main ways: axial and diametric. Axial magnetization runs through the length of the magnet, from one flat face to the other. This setup is great when you need strong, direct pull force, making it ideal for applications like holding, lifting, or linear motors where the magnet’s power is focused along its length.

On the other hand, diametric magnetization goes across the diameter, meaning the magnetic poles are on the curved sides instead of the ends. This type works best for rotational uses, like in motors and certain sensors, where the magnetic field needs to spin or interact differently.

If you’re not sure which magnetization your cylindrical magnet has, a simple way to check is by using a gaussmeter. Just scan along the length and diameter — the stronger reading shows the direction of magnetization. This quick test helps ensure you’re using the right magnet type for your project’s needs.

How Do Cylindrical Magnets Stack Up Strength Comparisons with Other Shapes

When it comes to strength, cylindrical magnets often outperform other common shapes, but their advantage depends on the application.

Compared to Disc Magnets: Cylindrical magnets have a longer magnetic field reach because of their shape, making them better for applications needing strong pull over a distance. Disc magnets are great when you need a flat surface for holding or mounting since their strength is focused right on their face.

Compared to Bar and Ring Magnets: Bar magnets are versatile and offer a steady magnetic field, but cylindrical magnets can deliver higher pull forces in a smaller package. Ring magnets, found often in MRI coils and electric vehicle (EV) rotors, provide unique field distributions that suit spinning components. Still, cylindrical magnets are preferred when you need strong, concentrated magnetic force along an axis.

Here’s a quick look at pull force differences by shape (values approximate and vary by size and grade):

| Magnet Shape | Typical Pull Force Range | Best Use Case |

|---|---|---|

| Cylindrical | High (up to several lbs) | Linear pull, deep magnetic reach |

| Disc | Moderate | Flat holding, surface mounts |

| Bar | Moderate to High | General purpose, steady fields |

| Ring | Varies | Rotational field applications |

This shows why cylindrical magnets are often the go-to choice for applications demanding powerful, focused magnetic strength, especially in US industries like manufacturing and tech development.

Real World Applications Where Cylindrical Magnets Strength Shines

Cylindrical magnets pack serious power, making them go-to choices across a range of real-world uses—both industrial and everyday.

Industrial Uses:

You’ll find these strong neodymium rod magnets inside motors and generators, where reliable magnetic force is key. They also play a big role in magnetic separation, especially in food production and pharmaceutical manufacturing. This helps keep products pure by removing metal contaminants quickly and efficiently.

Consumer and Tech Applications:

Cylindrical magnets are common in smartphone haptics and high-end audio drivers, delivering precise vibrations and sound quality. Their compact but powerful nature also suits medical implants where space is tight but performance can’t be compromised.

DIY and Hobby Projects:

For those who build or tinker, these magnets offer strong holding power without adding extra bulk. Whether you’re assembling magnetic tool holders or custom closures, cylinders give you dependable grip with a sleek profile.

NBAEM Custom Cylinder Case Study:

A client working on a wind turbine prototype needed magnets that could handle sustained stress and high pull forces. NBAEM provided custom-grade neodymium cylinders tailored to their specs, boosting efficiency and durability. This example shows how reliable sourcing and precise sizing can power advanced green tech.

Five Example Applications with Strength Benefits

- Electric motors in automotive and industrial equipment: High pull force ensures smooth and efficient operation.

- Medical devices like hearing aids and implants: Compact size meets necessary magnetic strength.

- Magnetic separators in food safety: Effective removal of metal contamination.

- Audio equipment drivers: Clear sound with tight magnetic control.

- DIY magnetic mounts and fixtures: Strong hold without bulky parts.

Cylindrical magnets combine shape and neodymium power to perform across industries, technologies, and hobbies alike—perfect for anyone needing magnetic strength that lasts.

The Limits of Strength Safety Temperature and Demagnetization Risks

Cylindrical magnets are powerful, but that strength comes with some important limits and safety concerns. First off, strong neodymium rod magnets can cause serious pinch injuries if you’re not careful. Always handle them slowly and keep them away from electronics and medical devices like pacemakers. These magnets can mess with sensitive equipment or cause harm to those with implants.

Temperature is another big factor. Most neodymium magnets, especially grades like N35 to N52, start losing strength above 176°F (80°C). If your application involves higher heat, consider alternatives like ferrite or Alnico magnets, which handle heat better but are less powerful.

Demagnetization risks come mainly from exposure to opposing magnetic fields or corrosion. If a magnet encounters a strong opposite field, it can lose some of its magnetism. That’s why many cylindrical magnets come with protective coatings like nickel-copper-nickel or epoxy. These coatings not only prevent rust but also help maintain magnetic strength over time.

For best handling and storage:

- Use gloves to avoid skin injuries and keep oils off the magnets

- Store magnets with steel keepers or separated by spacers to reduce accidental attraction

- Keep them dry and away from corrosive environments

NBAEM offers specially coated cylindrical magnets that extend lifespan in humid conditions, making them ideal for industrial or outdoor uses. Taking these precautions helps you get the most out of your magnets safely and keeps them strong for the long haul.

Choosing the Right Cylindrical Magnet Sizing Grades and Supplier Insights

Picking the right cylindrical magnet means balancing size, grade, and source quality. When deciding on diameter and length, remember that pull force grows with the magnet’s volume and the strength of its grade. A simple rule: larger volume plus higher grade equals stronger pull force. For example, doubling the length or diameter can significantly boost magnetic reach and force.

When it comes to grades, N42 magnets are a solid middle ground — affordable yet powerful enough for most applications. But if you need peak performance, N52 offers maximum strength with a premium price. Check out our detailed comparison of N42 vs N52 magnets to see what fits your project best.

Sourcing quality is just as important as size and grade. Look for suppliers like NBAEM who offer certified magnets meeting RoHS and REACH standards, ensuring safe materials and consistent performance. Ordering in bulk often lowers costs without sacrificing quality—perfect for industrial or large-scale needs.

Quick FAQs

-

How do I know what size to pick?

Start with your pull force need, then adjust diameter and length to hit that target.

-

Is N52 always better than N42?

Not always. N52 is stronger but pricier and sometimes overkill depending on the use.

-

Can I get samples before buying in bulk?

Yes, NBAEM provides samples so you can test performance firsthand.

Ready to find your perfect cylindrical magnet? Contact NBAEM for custom sizes, grades, and expert advice tailored to your needs.

Leave A Comment