What Exactly Is a Shuttering Magnet? Demystifying the Basics

A shuttering magnet is a smart, switchable permanent magnet system designed to hold formwork securely without the need for traditional fasteners like bolts or clamps. It is a useful construction magnet,encased in a tough steel housing, it delivers a strong, reliable grip that makes setting up precast concrete molds faster and safer.

Core Components

- Magnetic Array: The heart of the system, usually high-grade neodymium (NdFeB) magnets, providing powerful holding force.

- Activation Button: A handy switch that turns the magnet’s holding force on or off, allowing easy positioning.

- Adapter Interfaces: Various attachments or mounts that connect the magnet to different formwork types (steel or wooden).

How It Stands Out from Traditional Clamps

| Feature | Traditional Clamps | NBAEM Shuttering Magnets |

|---|---|---|

| Holding Force | Variable, often weaker | High-grade NdFeB magnets, up to 3,200 kg |

| Installation | Bolts, screws, manual tightening | One-button activation, no tools needed |

| Speed | Time-consuming | Quick positioning and release |

| Surface Compatibility | Limited | Adapters for steel and wood surfaces |

| Safety | Risk of injury from tools | Safer, no pinching or manual strain |

| Reusability | Limited by wear | Durable and reusable over years |

With NBAEM’s advanced neodymium magnets, the shuttering magnet system offers a firm, dependable hold that beats traditional clamps in both strength and convenience. It’s the go-to solution for modern precast concrete formwork fixing.

How Shuttering Magnets Work: From Activation to Secure Hold

Shuttering magnets use a clever magnetic circuit principle to switch between two modes for easy positioning and strong clamping. In the off-mode, the magnetic flux is contained inside the steel casing, so you can place and move the magnet freely on the steel platform without it sticking. When you’re ready, pressing the activation button switches the magnet on, redirecting the magnetic flux outwards to grip tightly onto the steel surface and hold the formwork firmly in place.

Here’s a simple step-by-step on using these magnets effectively:

- Place the shuttering magnet onto your steel platform or table.

- Press the activation button to engage the magnetic circuit.

- Align and fix the formwork or side rails against the magnet.

- Once secured, deactivate the lever or button to release if adjustments are needed.

A key factor in magnetic holding force is the air gap—even a tiny space between the magnet and steel reduces grip drastically. That’s why good surface contact is essential for maximum adhesion. NBAEM recommends cleaning and prepping the steel surface before use to ensure no rust, dust, or debris get in the way. Proper surface prep makes a huge difference for secure, stable clamping with less effort and worry.

For more on magnet properties that affect performance, check NBAEM’s detailed guide on what factors affect the properties of magnets. This will give you a clearer understanding of why preparation and correct use matter so much.

Types of Shuttering Magnets: Choosing the Right Fit for Your Project

Shuttering magnets come in several types to match different formwork needs. The standard box magnets are the most common, ideal for securing side rails on steel platforms. Their compact design and strong magnetic holding force make them perfect for typical precast setups.

For uneven surfaces or wooden formwork, stepped or adapter-equipped magnets offer better contact and grip. These models come with custom adapters that conform to irregular shapes or non-metallic materials, ensuring a firm hold without slipping.

When working with long elements like beams or large panels, bar or linear magnets distribute the holding force evenly along the length. This prevents gaps and holds extended molds securely, providing stability during concrete pouring.

Here’s a quick comparison of types:

| Magnet Type | Ideal Use | Holding Capacity | Key Advantage |

|---|---|---|---|

| Standard Box Magnets | Side rail fixing | Up to 3,200 kg (NBAEM) | Quick setup, strong hold |

| Stepped / Adapter Models | Uneven or wooden forms | Varies by adapter | Versatile, adjustable fit |

| Bar / Linear Magnets | Long, linear elements | High, distributed | Even holding, prevents warping |

NBAEM offers customized shuttering magnets tailored to specific project needs, combining high-grade NdFeB materials with adaptable designs. This versatility beats traditional clamps by saving time and reducing installation complexity, especially for tricky form geometries.

For a deeper look at magnetic materials used, check out our guide on industrial applications of magnetic materials.

Key Benefits: Why Shuttering Magnets Are a Must for Precast Efficiency

Shuttering magnets deliver clear advantages that boost productivity and safety in precast concrete work. Here’s why they stand out:

Time Savings

- Cut formwork installation time drastically — no drilling or hammering needed

- Quick setup and removal speeds up workflow, letting you pour more panels daily

Cost-Effectiveness

- Low initial investment with magnets reusable across many projects

- Fast ROI due to labor savings and reduced tool wear

Precision and Safety

- Secure hold without damaging formwork or steel tables

- Eliminates risks related to manual clamps, nails, or screws — fewer worker injuries

Versatility

- Work smoothly with various mold types: steel, wood, or composite forms

- Adaptable to uneven surfaces or custom shapes with available adapters

Industry Stats & NBAEM Case Study

| Benefit | Impact | Example from NBAEM Use |

|---|---|---|

| Installation Time | Up to 50% faster | Labor hours cut in half on large precast site |

| Reusability | 10+ projects | Magnets used repeatedly across multiple batches |

| Safety | Injury reduction | Zero clamp-related accidents reported |

| Cost Savings | 30% less labor | Significant drop in overhead costs |

Switching from traditional clamps to NBAEM’s high-grade neodymium shuttering magnets means smoother operations and safer worksites.

In short, shuttering magnets offer an unbeatable mix of speed, safety, and savings for modern precast concrete production.

Real-World Applications: Shuttering Magnets in Action Across Projects

Shuttering magnets have proven their worth across a range of real-world precast concrete projects. For example, when producing precast wall panels on tilting tables, these switchable magnets secure formwork quickly and firmly, speeding up the workflow without the need for drilling or welding. In slab production with blockouts, shuttering magnets hold the inserts precisely, ensuring perfect shapes while saving setup time.

They’re also ideal for custom precast elements like sandwich panels or beams, where varied shapes require adaptable and reliable magnetic formwork fixings. Whether your workshop focuses on small batches or you operate a large plant, magnetic clamps scale effortlessly to your production size, offering consistent holding force and quick repositioning.

NBAEM supports this versatility by supplying a wide range of shuttering magnets globally, backed by positive customer testimonials across industries. Their durable, high-grade neodymium magnets help precast manufacturers cut labor costs and improve safety—all while maintaining high precision in formwork installation.

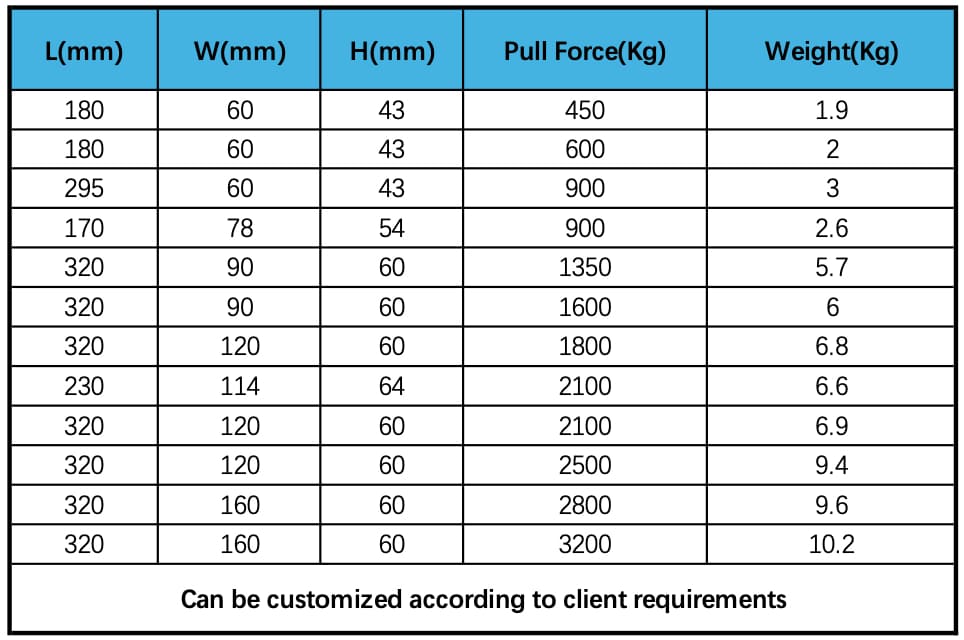

Specification of shuttering magnet

Installation, Maintenance, and Troubleshooting: Practical Tips for Longevity

To get the most out of your shuttering magnets, a few simple steps before and after use can extend their life and maintain peak magnetic holding force.

Pre-use checks:

Always clean the steel surfaces where the magnet will attach. Dust, oil, or paint reduce adhesion.

Wear gloves to avoid contaminating magnet surfaces with oils or dirt.

Inspect magnets for visible damage or rust before each job.

Daily cleaning and storage:

Wipe the magnets down after use with a dry cloth to remove debris.

Store magnets separately in a dry place to avoid accidental attraction or damage.

Use magnetic isolation plates or keep magnets apart to preserve their magnetic strength.

Common issues and fixes:

Rust: Remove surface rust promptly with a wire brush to keep the steel casing intact.

Debris stuck on the magnet face: Clean with a soft brush or cloth to ensure secure contact.

Reduced holding force: Check for air gaps caused by dirt or uneven surfaces.

Working on non-steel tables?

Since shuttering magnets rely on magnetic attraction, they won’t stick to aluminum or wooden platforms. You’ll need steel adapters or alternative clamping methods for such setups.

Quick Maintenance Checklist

| Task | Frequency | Notes |

|---|---|---|

| Surface cleaning | Before each use | Remove dust, rust, oil |

| Magnetic face inspection | Daily | Check for chips, cracks |

| Storage | After work | Keep dry, separated |

| Rust treatment | As needed | Use wire brush or rust remover |

| Functional test | Weekly | Confirm switch and hold force |

Following these basic maintenance and troubleshooting tips ensures your shuttering magnets deliver reliable strength and save time on every concrete formwork setup.

Selecting the Best Shuttering Magnet: Factors to Consider

Choosing the right shuttering magnet depends mainly on your project’s holding force requirements and the type of formwork you’re working with. Make sure the magnet’s strength matches the weight and material of your molds to avoid slips or repositioning during concrete pouring.

Budget versus durability is another big factor. While cheaper generics may save money upfront, higher-quality magnets like NBAEM’s 2,100 kg holding force model offer longer life, better performance, and quicker returns on investment through fewer replacements and less downtime.

Look for quality markers such as NdFeB purity and certifications to ensure you’re getting genuine switchable permanent magnets built for heavy-duty use. NBAEM magnets use premium neodymium rare earth materials, guaranteeing strong, reliable magnetic holding force combined with easy switch-off functionality. This makes them versatile and safe for precast concrete setups.

For an in-depth comparison and to help you pick the best fit, download our detailed buyer’s guide. It walks you through key specs, compatibility tips, and user advice to optimize your formwork clamping system effectively and cost-efficiently.

Explore our range and quality assurances at NBAEM to ensure your next project gets the magnetic performance it needs without compromise. You can also learn more about the fundamentals behind neodymium magnets on our page about what is a neodymium magnet.

[…] Previous What Is Magnetic Chamfer Guide Benefits Types and Uses in Precast Concrete […]

[…] Shuttering magnets: These usually come as U-shaped or rectangular blocks, perfect for slab production. They vary in load capacity to suit different casting weights and ensure strong fixation. […]

[…] damaging expensive tables or molds. That’s exactly where precast concrete magnets—also known as shuttering magnets or formwork magnets—come into play. These powerful, switchable magnetic boxes revolutionize form […]