If you’re working in precast concrete, you already know that traditional formwork can slow down production and drive up costs. Magnetic formwork is changing the game—offering a fast, reliable, and labor-saving alternative to bolts and clamps. These powerful neodymium-based systems hold side rails and accessories firmly on steel casting tables without the hassle of mechanical fasteners.

In this guide, you’ll discover exactly how magnetic formwork from NBAEM streamlines your precast workflow, cuts setup times in half, and boosts precision for defect-free elements. Ready to unlock efficiency and scale your production smarter? Let’s dive in.

magnetic formwork

The Fundamentals: How Magnetic Formwork Works in Precast Applications

Magnetic formwork is revolutionizing precast concrete production by simplifying the attachment and removal of formwork components. At its core, this system uses powerful yet controllable magnets that firmly hold steel formwork panels in place during casting, then release them effortlessly for demolding.

Core Components Breakdown

- Switchable Magnets: The heart of the system, these rare-earth neodymium magnets offer strong pull force when activated and can be turned off to release the formwork. Their switchable nature ensures easy control on-site.

- Steel Casings: Encasing the magnets, steel plates provide a magnetic surface to hold onto, creating a reliable fix without additional clamping.

- Anti-Magnetic Knobs: These adjust the magnetic field by blocking or redirecting it, enabling the activation or deactivation of the magnet’s hold with simple manual control.

- Adapters: Designed for seamless integration with various precast setups, adapters allow quick mounting of magnets on different formwork panels and surfaces.

Step-by-Step Mechanics

- Activation: The operator turns the anti-magnetic knob or lever, allowing the neodymium magnet to engage its full magnetic pull.

- Fixation: The magnet adheres strongly to the steel casing or formwork panel, securely fixing parts in place during concrete pouring.

- Deactivation: Once curing is complete, reversing the knob blocks the magnetic field, releasing the hold instantly.

- Tension Absorption: The system’s design mitigates stress and tension on the mold, protecting delicate geometries and maintaining alignment.

Material Science Angle

Neodymium magnets are prized in these systems for their exceptional pull force — often exceeding hundreds of kilograms in holding strength — while remaining compact and lightweight. Their corrosion-resistant coatings ensure durability in the harsh precast environment, resisting moisture and concrete by-products, which extends lifespan and maintains performance.

This blend of advanced material science and precise mechanical design makes magnetic formwork a dependable and efficient solution for modern precast applications.

Key Benefits: Why Magnetic Formwork Outperforms Traditional Methods

Magnetic formwork offers clear advantages over traditional methods in precast concrete production. Here’s why it’s a game-changer:

Efficiency Gains

- Time savings: Quick activation and release reduce setup and demolding times significantly.

- Increased production cycles: Faster turnovers enable more panels or slabs daily, boosting output.

Cost Reductions

| Factor | Magnetic Formwork Advantage |

|---|---|

| Labor | Less manual hammering and repositioning needed |

| Material Reusability | Magnets and steel casings last longer and can be reused multiple cycles |

| Table Preservation | No damage or wear on casting tables from hitting or clamps |

| ROI Calculation | Faster payback due to lowered costs and improved output |

Precision and Versatility

- Adaptable geometries: Suitable for different form shapes and sizes with custom accessories.

- Tight joint alignment: Strong magnetic force ensures perfect form contact and minimal leakage.

- Compatibility: Works well with diverse formwork types including traditional and modular systems.

Safety and Sustainability

- Reduced hammering risks: Fewer tools and physical strikes mean safer work conditions.

- Waste reduction: High durability cuts down on discarded parts and castings defects.

- Magnet recycling: Rare earth magnets like neodymium can be recovered and reused, lowering environmental impact.

Using magnetic formwork translates to a smoother, safer, and more cost-effective precast process. For those interested in the core magnet technology behind these benefits, detailed info on neodymium magnets and their properties can be found here.

Types of Magnetic Formwork Systems: Choosing the Right Fit for Your Operation

When selecting magnetic formwork systems, it’s key to match the right type to your production needs. Here’s a quick breakdown:

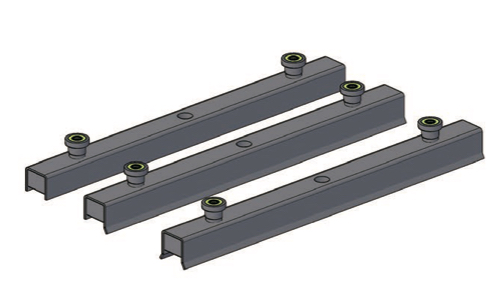

- Shuttering magnets: These usually come as U-shaped or rectangular blocks, perfect for slab production. They vary in load capacity to suit different casting weights and ensure strong fixation.

- Profile-integrated systems: These are pre-assembled rails with embedded magnets, designed for modular molds. They allow quick adjustments and ensure tight alignment for complex shapes, enhancing overall casting efficiency.

- Accessory ecosystems: To handle complex precast elements, accessories like magnetic chamfer strips, recess formers, and lifting inserts integrate seamlessly with both shuttering and profile systems. This adds flexibility for corners, edges, and embedded features.

- Customization options: Many manufacturers offer scalable solutions and OEM bespoke magnetic circuits tailored to specific needs, from adjusting pull forces to designing unique shapes to fit specialized forms.

Choosing the right system affects everything from cycle speed to casting accuracy. To ensure optimal performance in your setup, consider factors like load requirements, mold complexity, and adaptability.

Real-World Applications: Magnetic Formwork in Action Across Industries

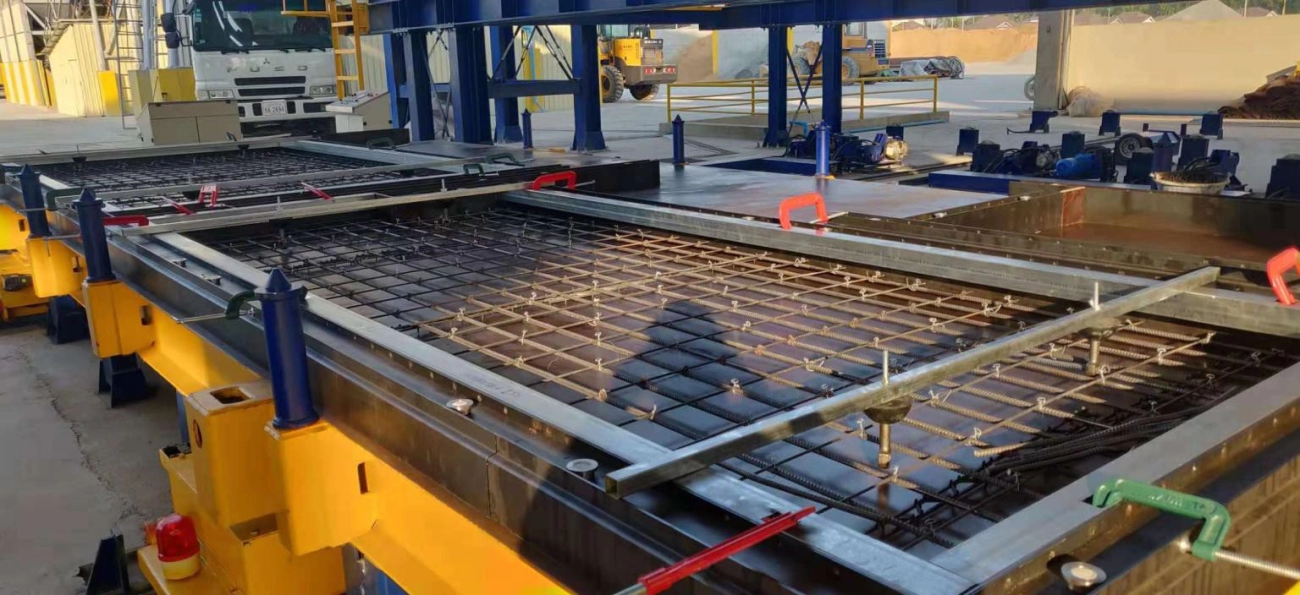

Magnetic formwork is making a strong impact across various precast concrete sectors. In precast factories, especially for wall panel production, using magnetic systems speeds up the process significantly. By cutting down the time spent on assembly and demolding, cycle times shrink, letting manufacturers boost output without extra labor costs.

Specialized applications also benefit greatly. Magnetic formwork handles solid slabs, double walls, and complex recesses smoothly, while its vibration tolerance suits tilt-up construction well. This adaptability means fewer defects and cleaner surfaces, which reduces rework and waste.

Looking ahead, automation is becoming a major trend with magnetic systems. Integrating switchable magnets into robotic mold handling and demolding improves precision and consistency. Plus, hybrid off-site construction methods are adopting these formwork solutions to speed up building schedules and maintain quality. Regional uptake is growing, especially in markets pushing for higher efficiency and sustainability.

For those wanting a deeper dive into the magnet technologies behind these advances, exploring NBAEM’s insights on neodymium magnets can be eye-opening, especially how they optimize concrete demolding efficiency and durable formwork fixation solutions.

Implementation Best Practices: Maximizing ROI with NBAEM Solutions

Getting the most from your magnetic formwork starts with a solid plan. First, conduct a thorough site assessment focusing on your table steel quality, load needs, and current workflow. High-quality steel tables ensure strong magnetic fixation and longer magnet life, which directly impacts your production reliability.

Next, follow strict installation protocols. NBAEM offers comprehensive training for operators, emphasizing correct magnet placement, safe handling, and storage to maintain magnet performance. Regular maintenance schedules are critical to avoid unexpected downtime and keep your system running smoothly.

When issues arise, NBAEM’s quick-swap adapters simplify troubleshooting. These pre-engineered solutions allow fast magnet replacement or repositioning without major disruptions, saving you time and avoiding costly delays.

Track your success by measuring:

- Demolding speed improvements

- Reduction in defect rates

- Overall energy savings through fewer mechanical aids and faster cycle times

Implementing NBAEM magnetic formwork with these best practices optimizes precast production efficiency, increases your return on investment, and leads to more consistent, high-quality results. For technical insights on magnet activation and durability, explore NBAEM’s detailed resources like their magnet machining processes which can help understand product longevity under site conditions.

Why Partner with NBAEM: Your Trusted Source for Premium Magnetic Materials

When it comes to magnetic formwork, NBAEM stands out as a global leader with decades of experience in rare earth magnets and industrial shuttering systems. Our solid track record is backed by rigorous certifications and a strong presence in markets worldwide, proving our commitment to quality and reliability.

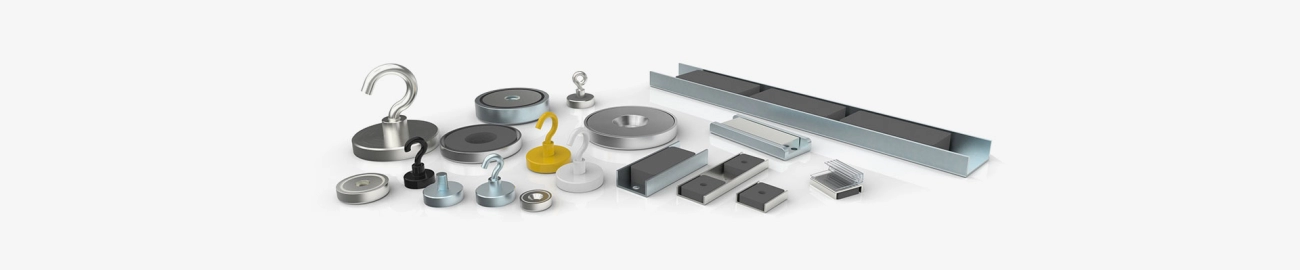

Our product range covers everything from powerful shuttering boxes and versatile side rail profiles to custom neodymium concrete formwork magnets tailored to your specific needs. Detailed spec sheets help you select the right solutions for your precast casting bed magnets and formwork fixation requirements.

Clients consistently highlight our dependable performance and responsive support as key reasons to choose NBAEM. We value long-term partnerships and focus on providing smooth installation, maintenance, and troubleshooting assistance.

Ready to boost your precast production efficiency? Contact us today for a personalized consultation or to request samples of our magnetic box for precast applications. Discover how NBAEM’s magnetic materials can transform your workflow and ROI with trusted, high-quality shuttering magnets,magnetic chamfer ,etc.

Leave A Comment