Project Description

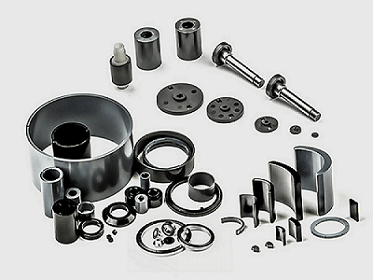

Bonded magnet

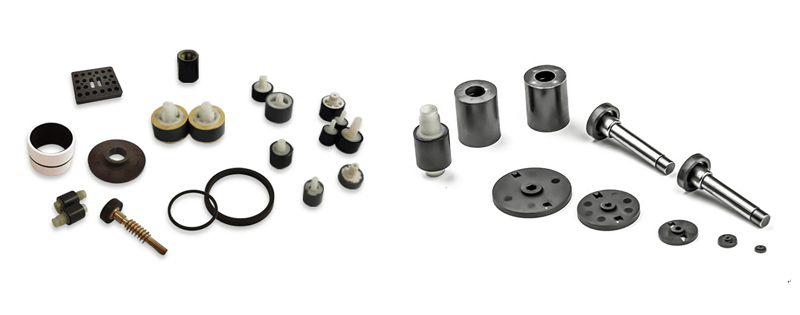

NdFeB magnets can be classified as sintered or bonded, depending on the manufacturing process used. A bonding magnet is a complex composed of magnetic powder, adhesive and appropriate additives. It is made by compression molding or injection molding the mixture of NdFeB magnetic powder and binder.

Bonded neodymium magnets have a great resistance against corrosion, but it is still advisable to provide them with a coating so that the durability is optimal. Due to the isotropy, bonded magnets can be magnetized in different directions.

Bonded Magnet Applications

Bonded magnets are mainly used in different motors and sensors.It also makes more application possible than sintered magnets. For example , the use of higher-density bonded neodymium magnets is helpful in achieving weight and volume reduction in permanent magnet motors, resulting in raw material cost savings.

- Sensors

- Automobiles motors

- HDD motors

- Pump-related Motors (Water, Oil Pump)

- Power Tools

- Office Appliances

- Home Appliances

- Encoder

- Medical healthcare

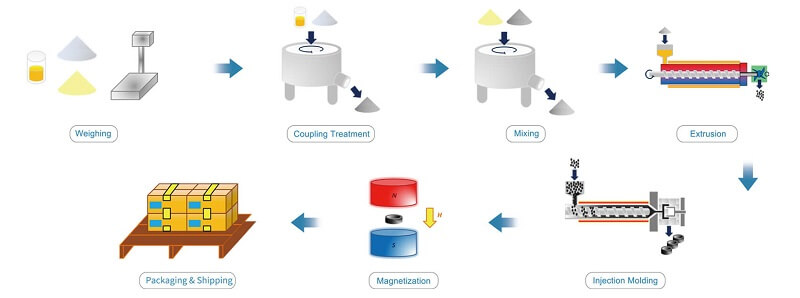

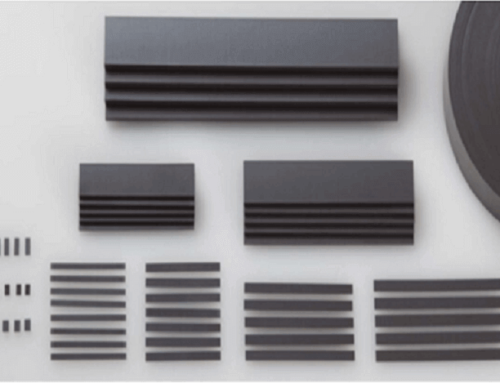

Injection molded magnets

Injected magnets are bonded magnets produced by means of injection molding after mixing and granulating thermoplastic resin and magnetic powder. We call plastic magnets. Injection molded magnet has the following characteristics:

- Complicated shapes can be produced, with high dimensional accuracy and good consistency.

- Smooth appearance, anti-vibration, impact resistance and anti-cracking.

- Binder Types :Nylon / PPS / Polyamide.

- Temperature Range -40c – 180c

- Very Tight tolerances off tool ( 0.002 -0.003 Typical )

- Very good mechanical strength

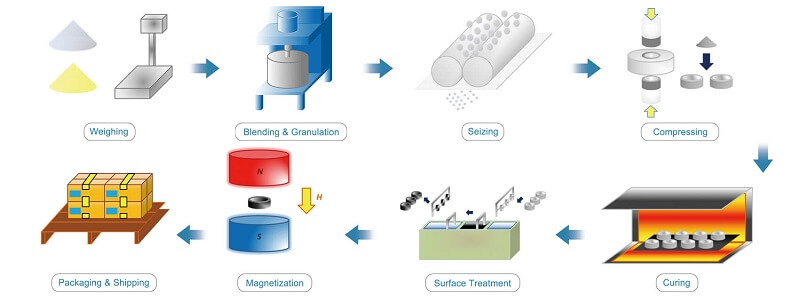

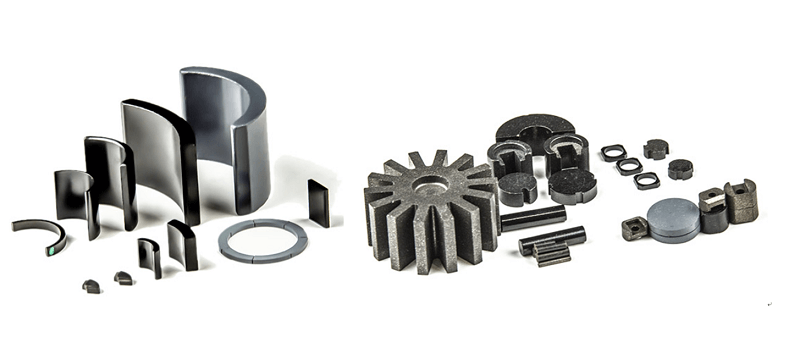

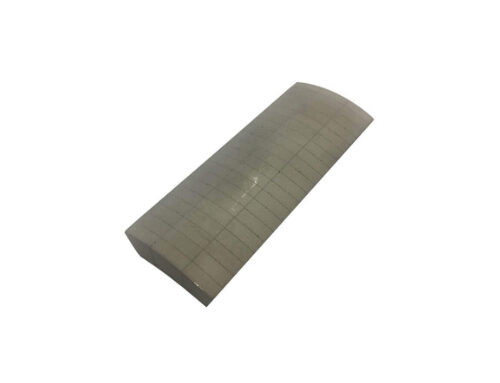

Compression molded magnets

The NdFeB magnetic powder and the binder are mixed according to a certain ratio, granulated and then pressed in a mold.

Compression molded magnet has the following characteristics:

- The product has high dimensional accuracy: it can meet the accuracy requirements in one molding, and generally does not require mechanical processing.

- Free formation of product shape: it can be made into rings, cylinders, discs, tiles, blocks and various-shaped magnets.

- Excellent magnetic performance: The BH(max) is three times that of anisotropic ferrite. With high intrinsic coercivity, the product features simple production, short process, stable performance in batch production.

- Flexible magnetization methods: the magnetization can be axial, radial, spoke wise and skew magnetization etc.

- Good corrosion resistance and outstanding surface quality: The surface of the product is coated with epoxy resin that features excellent corrosion resistance.

- Temperature Range -40c – 165c

- Good mechanical strength

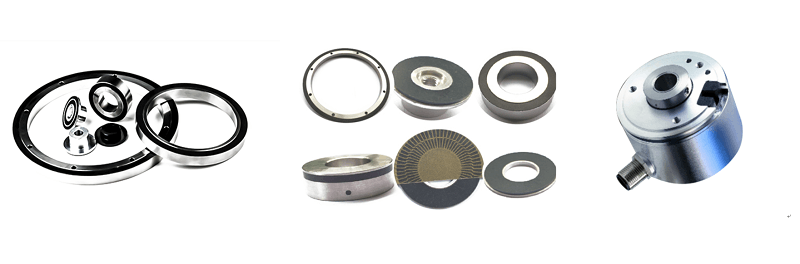

Magnetic Encoder

Magnetic encoders for precision CNC machine tools.

There are 3 major components in a magnetic encoder:

- Sensing Circuit

- A rotating wheel or ring

- A series of magnetic poles around the circumference of the wheel or ring

Our magnet for magnetic encoder available for mass production include those with 64 poles, 64+62 poles, 64+3 poles, 82 poles, 102 poles, 124 poles, 162 poles, 192 poles, 242 poles, 326 poles etc.

REQUEST A QUOTE

Looking for a certain size? Please see the different sizes of magnets as follows. If you require a specific size that is not available on our website, please contact us for a custom neodymium magnet quote.