Project Description

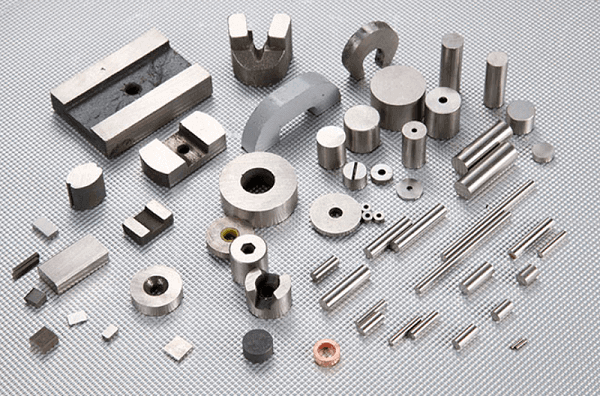

AlNiCo magnet

AlNiCo Magnets are made of the alloy of Aluminum-Nickel-Cobalt which possesses excellent temperature stability and high residual induction. AlNiCo magnets have a low coercive force that limits their applications in many cases. Casting and sintering are two major processes used to manufacture the AlNiCo magnets.

Alnico Magnets has very good resistance to corrosion and high max working temperature, which can reach 550deg.C. They are widely used in high stability fields as military, aerospace, automobiles, and security system etc. Even if other materials offer higher energy and coercivity values, the huge remanence and thermal stability of Alnico magnets make it the ideal cost-effective material for certain applications. Though alnico magnets have largely been replaced by stronger neodymium magnets like NdFeB magnets and Smco magnets they are still widely used in the manufacturing of sensors, guitar pickups, loudspeakers, and many other everyday household objects.

AlNiCo Magnet Applications

Alnico magnets are widely used in industrial and consumer applications where strong permanent magnets are needed. In many applications they are being superseded by rare-earth magnets, whose stronger fields (Br) and larger energy products (B·Hmax) allow smaller-size magnets to be used for a given application. Extremely resistant to demagnetization

Some examples are:

- Electric motors

- Electric guitar pickups

- Microphones

- Sensors

- Loudspeakers

- magnetron tubes

- cow magnets

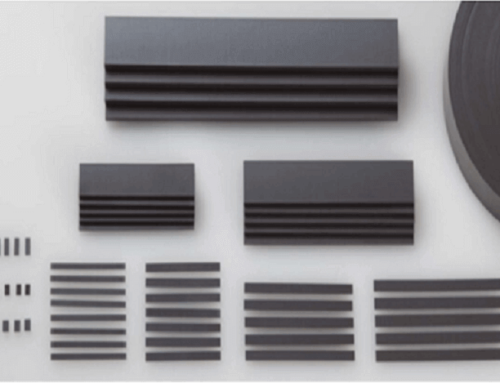

Cast AlNiCo magnets

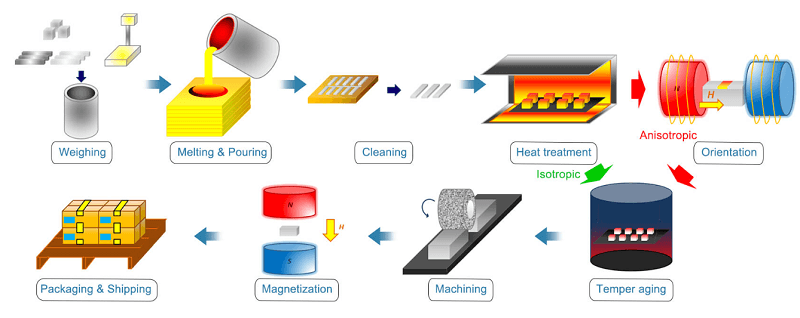

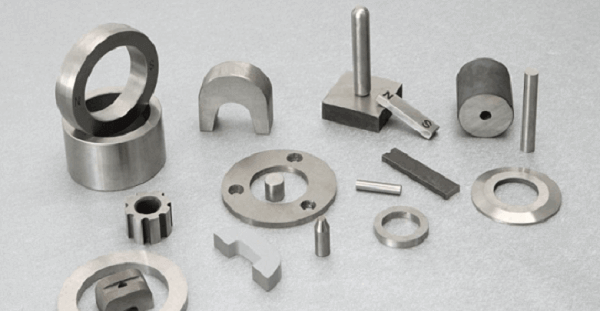

The majority of AlNiCo magnets are cast type. Cast AlNiCo magnets are manufactured by conventional foundry processes. AlNiCo alloys with different composition are melted and poured into the resin bonded sand molds, then solidified material with a rough surface will undergo heat treatment and cooling process. Cast AlNiCo magnets can be divided to the isotropic form and anisotropic form base on whether apply the magnetic field to orient magnets during the cooling process. For cast AlNiCo magnet, its anisotropy is a kind of shape anisotropy which associated with elongated Fe-Co particles in a Ni-Al matrix aligned parallel to the magnetic field during spinodal decomposition of the alloy. Therefore, material will be machined to specific geometry and tolerance after heat treatment process.

Sintered AlNiCo magnets

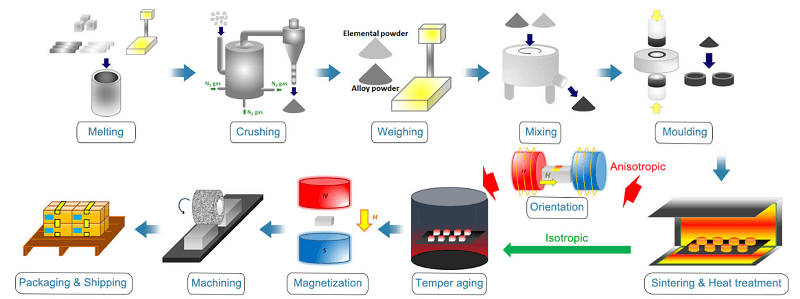

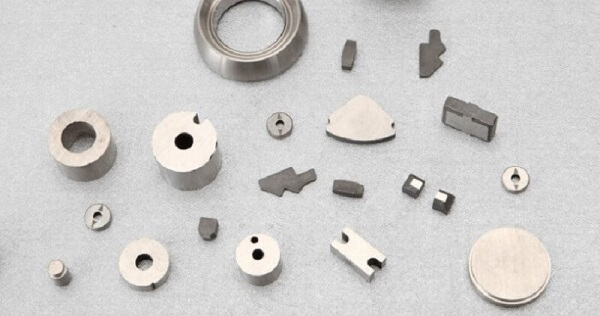

Sintered AlNiCo magnets are manufactured by powder metallurgy technology which similar with other sintered magnets. Its overall magnetic performance is slightly low than cast AlNiCo magnets, thus not commonly used like the latter. Sintered AlNiCo magnets are well adapted for small-sized, thin, light, and complex shaped magnets. Beside high dimensional accuracy and tight tolerance, It also has superior mechanical strength and machinability. Viewing from the production, sintered AlNiCo magnets have higher utilization ratio of material, lower composition segregation and magnetic performance fluctuation compared to the cast AlNiCo magnets.

REQUEST A QUOTE

Looking for a certain size? Please see the different sizes of magnets as follows. If you require a specific size that is not available on our website, please contact us for a custom neodymium magnet quote.