Project Description

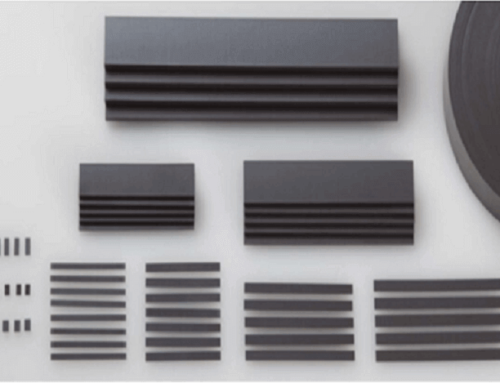

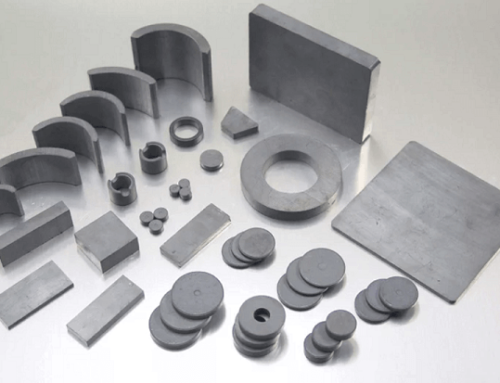

FeCrCo magnet

FeCrCo magnets were developed in the 1970’s. The FeCrCo permanent magnet alloy is known for its ductility and machinability prior to the final heat treatment. At this point in the process, the low cobalt material can be machined as if it was soft steel. lt can be bent and heat-treated with a curved field to form a horseshoe magnet.The simplified processes of manufacturing and magnetization, along with its nigh working temperature and significantly reduced cobalt content, often enable it to outshine other permanent magnets.

As a machinable magnetic material, magnetic properties of FeCrCo magnets are is equivalent to AlNiCo5’s and various options can be utilized to machining process, include drilling, milling, planning, grinding, and stamping, thus can manufacture micro, light, thin, and complex shaped components. The minimum wire diameter and the thinnest thickness of strip only 0.05mm and 0.1mm, respectively. Usage of Cobalt not only influences the intrinsic coercivity, but also affects machinability of material. The temperature stability and corrosion resistance of FeCrCo magnets is also outstanding. Its curie temperature and maximum working temperature can reach 680 degrees Celsius and 400 degrees Celsius, respectively. Hydrogen resistance expands the range of FeCrCo magnet in some specific applications.

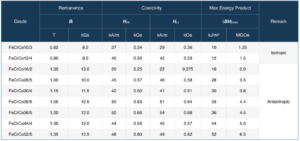

FeCrCo Magnet Magnetic Properties

REQUEST A QUOTE

Looking for a certain size? Please see the different sizes of magnets as follows. If you require a specific size that is not available on our website, please contact us for a custom neodymium magnet quote.