Understanding Magnetic Sensors and Their Types

Magnetic sensors detect changes in magnetic fields and convert them into electrical signals. Their core function relies on the interaction between magnetic fields and sensor elements, enabling UAVs to measure orientation, position, and motion accurately. These sensors are essential components in unmanned aerial vehicles (UAVs) for navigation, motor control, and obstacle detection.

Common Types of Magnetic Sensors Used in UAVs

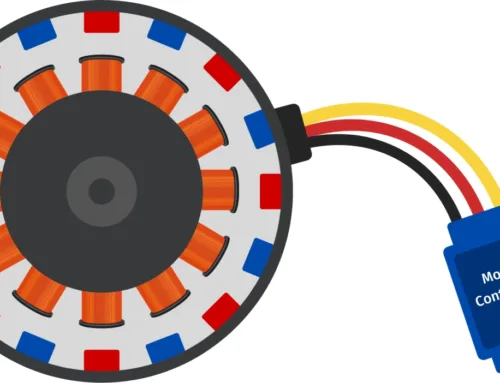

1. Hall Effect Sensors

- Operate on the Hall effect principle, generating voltage when exposed to a magnetic field perpendicular to the current flow.

- Widely used for rotor position sensing and brushless motor control in UAVs due to their simplicity and robustness.

2. Magnetoresistive Sensors

- Change electrical resistance in response to magnetic fields.

- Types include:

- Anisotropic Magnetoresistive (AMR): Good sensitivity for compass applications.

- Giant Magnetoresistive (GMR): Higher sensitivity than AMR, suitable for precise navigation systems.

- Tunnel Magnetoresistive (TMR): Offers excellent sensitivity and low power consumption, ideal for advanced UAV sensor suites.

3. Fluxgate Sensors

- Measure magnetic field strength by detecting the nonlinear magnetization of ferromagnetic cores.

- Known for high accuracy and stability, often used in high-end UAV navigation systems for compass correction.

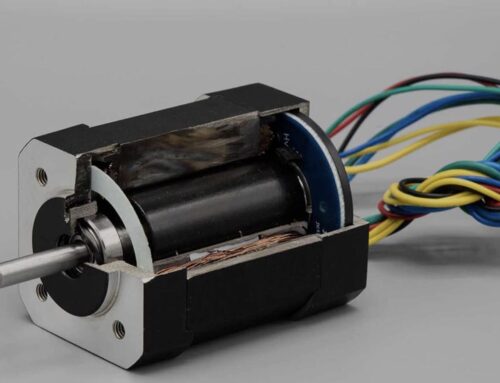

4. Inductive Magnetic Sensors

- Detect magnetic fields through inductance changes, mainly employed in proximity sensing and speed measurement applications.

Comparison of Sensor Types

| Sensor Type | Sensitivity | Size | Power Consumption | Cost | Typical UAV Applications |

|---|---|---|---|---|---|

| Hall Effect | Moderate | Small | Low | Low | Motor control, basic navigation |

| AMR | High | Small | Moderate | Moderate | Compass, orientation sensing |

| GMR | Very High | Small | Moderate | Higher | Precision navigation, motor feedback |

| TMR | Very High | Very Small | Low | High | Advanced navigation, sensor fusion |

| Fluxgate | Very High | Medium | Moderate to High | High | Accurate compass, environmental sensing |

| Inductive | Moderate | Varies | Low to Moderate | Moderate | Proximity detection, speed sensing |

Each sensor type serves specific UAV needs balancing sensitivity, size, power, and cost. Selecting the appropriate sensor depends on the UAV’s operational requirements and mission profile. For the U.S. market, emphasis on advanced magnetoresistive sensors like GMR and TMR is growing due to their superior sensitivity and integration compatibility with modern UAV systems.

Role of Magnetic Sensors in Modern UAVs

Magnetic sensors play a crucial role in making modern UAVs smarter and more reliable. They help improve navigation by enhancing compass accuracy, which is essential for precise orientation during flight. Unlike GPS alone, magnetic sensors provide real-time directional data, keeping drones on course even in challenging environments.

For motor control, these sensors offer precise feedback to brushless motors, ensuring smooth and efficient operation. This precision extends battery life and boosts overall UAV performance, which is especially important for commercial and industrial drones flying longer missions in the U.S.

Magnetic sensors also assist in proximity sensing and obstacle detection. By detecting magnetic fields and nearby metallic objects, they add an extra layer of safety during flight, reducing collision risks in crowded or complex spaces.

Managing magnetic field interference is another key function. UAV components and external sources can generate interference that messes with sensor readings. Advanced magnetic sensors help filter out this noise, maintaining reliability.

Finally, UAV stabilization benefits from integrating magnetic sensors with inertial measurement units (IMUs) and GPS. This sensor fusion provides stable flight control by combining directional and positional data, making drones more responsive and accurate in their movements.

Technological Advancements in Magnetic Sensor Design for UAVs

Magnetic sensors for UAVs have come a long way thanks to new tech that makes them smaller, smarter, and tougher. Miniaturization allows these sensors to fit right into compact drone electronics without adding extra weight or bulk. This is a big deal for U.S. customers who want lightweight drones for longer flight times and better performance.

Sensitivity improvements mean these sensors can detect even tiny magnetic fields, which boosts navigation accuracy and motor control. Noise reduction techniques help cut down interference from other electronics or environment, keeping sensor readings clean and reliable during complex operations.

Modern magnetic sensors are also built to handle wider temperature ranges and harsher conditions, making them perfect for drones flying across various U.S. climates—from hot Arizona deserts to cold Alaskan skies. This durability ensures sensors continue to perform well even under extreme weather.

We’re seeing strong integration between magnetic sensors and IoT systems, enabling UAVs to connect with smart networks for autonomous flight, live data updates, and predictive maintenance. This connectivity plays a vital role in commercial and industrial drone applications across the country.

Some current UAV models use advanced magnetoresistive sensors paired with onboard AI algorithms, providing better heading accuracy and motor feedback. These examples showcase how innovations in magnetic sensor design are pushing drone capabilities forward while meeting the high standards U.S. customers expect.

Materials and Manufacturing Considerations

The quality of magnetic materials directly impacts how well magnetic sensors perform in UAVs. High-grade materials ensure better sensitivity, stability, and durability, which are key for reliable navigation and motor control.

NBAEM offers advanced magnetic materials designed specifically for sensor applications. Their compositions deliver strong magnetic properties like consistent flux density and low noise, helping sensors work accurately even in challenging environments.

Customization and scalable production are also important. NBAEM can tailor materials to meet different UAV requirements—whether it’s lightweight sensors for small drones or more robust solutions for larger UAVs used in commercial or military settings. This flexibility supports efficient manufacturing and integration.

Sustainability and reliability remain top priorities. Using materials that withstand harsh conditions and reduce environmental impact aligns well with what the U.S. UAV market demands, especially in strict regulatory climates. NBAEM’s focus on these factors helps boost sensor lifespan and overall UAV performance.

Challenges and Solutions in Magnetic Sensor Deployment on UAVs

Magnetic sensors in UAVs face a few key challenges that need smart solutions to keep things running smoothly.

- Magnetic interference: UAV components like motors and batteries can cause magnetic fields that interfere with sensors, leading to inaccurate readings. Environmental factors like nearby power lines or metal structures also add noise. To combat this, UAV designers use shielding and strategic sensor placement to minimize interference.

- Calibration and compensation: Regular calibration is essential to keep sensors accurate. Advanced compensation techniques correct sensor drift caused by magnetic interference and temperature changes. Many modern UAV systems offer automatic calibration routines that adjust in real time.

- Power consumption and weight: Magnetic sensors need to be energy-efficient and lightweight to fit within UAV power budgets and flight limits. Solutions include selecting low-power sensor types and optimizing sensor circuitry to extend UAV flight time without adding unnecessary bulk.

- Durability under tough conditions: UAVs often operate at high speeds and in harsh weather, exposing sensors to vibrations, temperature swings, moisture, and dust. Robust sensor designs with rugged materials and protective coatings help maintain performance even in these conditions.

By addressing these challenges through smart design and calibration, magnetic sensor technology in drones keeps UAV navigation sensors reliable and precise for a wide range of missions.

Future Trends and Innovations in Advanced Magnetic Sensors in Modern UAVs

Magnetic sensor technology in drones is evolving fast, and the future looks promising. New types of magnetic sensors are being developed with better sensitivity and smaller sizes, making them ideal for the tight spaces in modern UAVs. These emerging sensors promise improved accuracy and much lower power use, which is critical for longer flight times and more reliable operations.

One big trend is the integration of magnetic sensors with AI and predictive analytics. This means UAVs can use sensor data smarter, anticipating navigation challenges or motor issues before they happen. Combining magnetic sensor inputs with AI also improves autonomous flight, offering smoother control and better obstacle avoidance.

The impact of these innovations will be felt across commercial, military, and consumer UAV markets. For commercial drones, expect more precise delivery and inspection capabilities. Military UAVs will benefit from enhanced navigation and stealth. Consumers will see more reliable drones with smarter navigation and better battery life.

Leave A Comment