Anisotropic Magnet vs Isotropic Magnet?

Have you ever wondered why some magnets are stronger in one direction than others? Let’s dive into anisotropic and isotropic magnets.

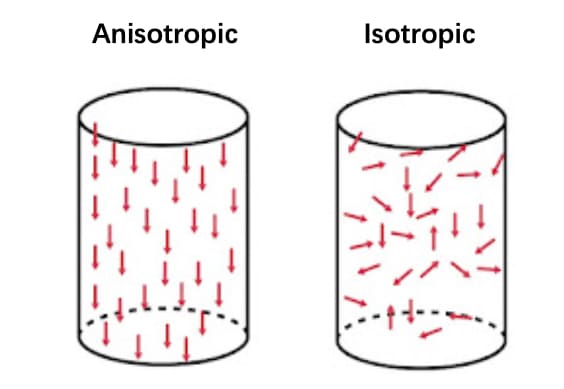

Anisotropic magnets are designed for strength in a single direction, while isotropic magnets offer flexibility but with lower magnetic performance.

Anisotropic vs Isotropic

Magnets are everywhere—in motors, sensors, and even medical equipment. Knowing their orientation and properties can make a big difference in choosing the right one.

What is meant by magnetic anisotropy?

Magnets may look simple, but their inner structure can be complex. Magnetic anisotropy defines how a magnet’s properties change with direction.

Magnetic anisotropy means a material has a preferred direction of magnetization, often achieved through special manufacturing processes.

Dive deeper: Understanding anisotropy

Magnetic anisotropy comes from the arrangement of magnetic domains inside a material. In an anisotropic magnet, these domains align in a single direction, creating a stronger magnetic field along that axis. This is achieved by applying a magnetic field during manufacturing, which locks the alignment of magnetic grains.

| Factor | Isotropic Magnets | Anisotropic Magnets |

|---|---|---|

| Grain alignment | Random | Aligned |

| Magnetization | Any direction | One direction |

| Strength | Lower | Higher |

| Manufacturing | Simpler | Complex |

From my experience, clients in the motor and sensor industries often choose anisotropic magnets because they provide higher energy output in the desired direction. However, they must ensure proper alignment in their devices to maximize performance.

What is the difference between isotropic and anisotropic magnets?

Choosing the right magnet can make or break your project. So, how do isotropic and anisotropic magnets differ?

Isotropic magnets can be magnetized in any direction but are weaker, while anisotropic magnets have a set magnetization direction and offer higher strength.

Difference between Anisotropic and isotropic(photo from Alliance LLC)

Dive deeper: Comparing isotropic and anisotropic magnets

Let’s break down the main differences between these two types of magnets:

1. Manufacturing Orientation

Isotropic magnets are made without any external magnetic field. Their grains are randomly oriented, which allows them to be magnetized in any direction but with lower energy density.

Anisotropic magnets, on the other hand, undergo a process where a magnetic field is applied during production. This orients the grains in a preferred direction, increasing magnetic strength along that axis but restricting magnetization in other directions.

2. Magnetic Properties

- Isotropic: Lower magnetic strength, but flexible in applications where multi-directional magnetization is needed.

- Anisotropic: Higher magnetic strength, suitable for high-performance applications like motors and sensors.

3. Cost and Complexity

Isotropic magnets are cheaper to produce and require less precision. Anisotropic magnets cost more due to their complex manufacturing but offer better performance.

Here’s a table summarizing key differences:

| Feature | Isotropic Magnets | Anisotropic Magnets |

|---|---|---|

| Magnetization | Any direction | One direction |

| Magnetic Strength | Lower | Higher |

| Flexibility | More flexible | Less flexible |

| Cost | Lower | Higher |

| Manufacturing Process | Simple | Complex |

I recall a project where a client initially used isotropic magnets for a toy design but later switched to anisotropic magnets when they needed stronger performance in a fixed orientation.

Conclusion

Understanding isotropic and anisotropic magnets helps in selecting the right material for your application. Each has its strengths, costs, and ideal use cases.

My Role

About me

Brand Name: NBAEM Magnet

Slogan: Specialized in magnetic materials

Website: nbaem.com

Our Mission:

NBAEM Magnet is a magnet company with 15 years of experience. We specialize in various types of magnetic materials, aiming to help each customer create cost-effective customized magnets and magnetic components that meet their specific requirements. We provide high-quality pre-sales and after-sales services, along with relevant technical support.

About me:

NBAEM was founded by me—a passionate professional in the magnet industry. I started my career at a magnet factory and later established a successful magnet and magnetic assembly company. Through my journey in the magnet industry, I have helped many clients grow their businesses. By sharing my expertise and experience, I aim to help clients find the right solutions.

Leave A Comment