If you’re asking, “Are neodymium magnets better than SmCo?” you’re not alone. Choosing between neodymium (NdFeB) magnets and samarium cobalt (SmCo) magnets can be tricky—each has unique strengths that make them ideal for different applications. Whether you’re an engineer, designer, or buyer, understanding their key differences in magnetic strength, temperature resistance, and durability is crucial before making a decision. In this article, we’ll break down everything you need to know to decide which rare-earth magnet truly fits your project—and when SmCo might outperform neodymium despite the latter’s popularity. Let’s get into the facts behind these powerful magnets.

Understanding the Basics What Are Neodymium and SmCo Magnets

Neodymium and SmCo (Samarium Cobalt) magnets are both types of rare earth magnets known for their powerful magnetic properties. These magnets are widely used across various industries due to their strength and reliability, but they differ significantly in composition, manufacturing, and performance characteristics.

Composition and Manufacturing Process

- Neodymium magnets, commonly referred to as NdFeB magnets, are primarily made from an alloy of neodymium, iron, and boron. The manufacturing involves melting the raw materials followed by a powder metallurgical process that includes milling, pressing, sintering, and annealing to form dense, high-strength magnets.

- SmCo magnets are composed of samarium and cobalt. In contrast to neodymium magnets, SmCo magnets are produced mainly through sintering or casting processes. This results in a magnet that is stable in high temperatures and resistant to corrosion but generally more brittle.

Magnetic Properties Overview

- Strength: Neodymium magnets typically offer higher magnetic strength, often measured by maximum energy product (BH max), making them the strongest permanent magnets available.

- Coercivity: Both magnets have high coercivity, meaning they resist demagnetization, but SmCo magnets tend to maintain their magnetism better in high-temperature or harsh environments.

- Temperature Resistance: SmCo magnets stand out with superior temperature stability, performing well at temperatures up to 350°C or higher. Neodymium magnets, however, lose strength significantly above 80-150°C depending on the grade.

Typical Applications

- Neodymium magnets are ideal for applications requiring strong magnetic fields in compact sizes, such as consumer electronics, electric motors, headphones, and renewable energy devices.

- SmCo magnets serve well in high-temperature environments or where corrosion resistance is crucial, making them common in aerospace, defense, automotive sensors, and medical devices.

Both magnet types are essential in modern technology, but choosing the right one depends on specific performance needs and operating conditions. For more on the difference between NdFeB and SmCo magnets, explore our detailed comparison here.

Key Performance Comparison

When comparing neodymium (NdFeB) and samarium cobalt (SmCo) magnets, here’s how they stack up on key factors:

Magnetic Strength

- Neodymium magnets have the highest magnetic strength among rare earth magnets, with a maximum energy product (BH max) between 28 to 52 MGOe, making them very powerful for their size.

- SmCo magnets are strong but typically range from 16 to 32 MGOe, so they’re a bit weaker overall.

Temperature Stability and Operating Range

| Property | Neodymium Magnets | SmCo Magnets |

|---|---|---|

| Max Operating Temp | 176°F to 302°F (80°C-150°C) | 356°F to 572°F (180°C-300°C) |

| Temperature Stability | Lower, loses magnetism faster at high temps | High, maintains magnetism well in heat |

SmCo magnets shine in high-temperature environments, while neodymium magnets lose strength when heated beyond their limits.

Corrosion Resistance and Durability

- Neodymium magnets corrode easily and usually need a protective coating like nickel or epoxy.

- SmCo magnets are naturally resistant to oxidation and don’t need as much protection, making them more durable in harsh conditions.

Mechanical Hardness and Brittleness

- Neodymium magnets are hard but more brittle, easier to chip or crack if mishandled.

- SmCo magnets are also brittle but slightly tougher, better for applications where mechanical stress is a factor.

Cost and Availability

- Neodymium magnets are cheaper and more widely available thanks to large-scale production and abundant supply chains.

- SmCo magnets cost more due to complex manufacturing and rarer materials, so they’re often reserved for specialized uses.

This table sums it up:

| Feature | Neodymium Magnets | SmCo Magnets |

|---|---|---|

| Magnetic Strength (MGOe) | 28–52 | 16–32 |

| Max Operating Temp (°F) | 176–302 | 356–572 |

| Corrosion Resistance | Low (needs coating) | High (natural) |

| Mechanical Toughness | Brittle, less tough | Slightly tougher |

| Cost | Lower | Higher |

| Availability | High | Moderate |

This comparison should help you match the magnet type with your project’s magnetic strength, temperature needs, and durability requirements.

Environmental and Application Considerations

When choosing between neodymium and SmCo magnets, it’s important to think about the conditions they’ll face.

Performance in Harsh Environments

SmCo magnets excel in tough environments. They can handle exposure to moisture, chemicals, and corrosion much better than neodymium magnets. Neodymium magnets tend to corrode easily unless coated with protective layers like nickel or epoxy.

Suitability for High Temperature Applications

SmCo magnets are the go-to choice for high temperature use. They maintain their magnetic strength at temperatures up to 350°C (662°F), while neodymium magnets typically max out around 80-150°C (176-302°F) depending on grade. If your application involves heat—like motors or aerospace parts—SmCo might be the safer bet.

Sensitivity to Oxidation and Protective Coatings

Neodymium magnets are quite sensitive to oxidation. Without protective coatings, they quickly lose magnetic performance and suffer surface damage. SmCo magnets have inherent resistance to oxidation, reducing the need for heavy coatings and making them more durable in corrosive conditions.

Impact of External Magnetic Fields and Demagnetization Risk

Both magnets can be demagnetized by strong external fields, but SmCo magnets have higher coercivity—meaning they resist demagnetization better than neodymium magnets. This makes SmCo a better choice in applications exposed to fluctuating magnetic environments or where long-term stability is critical.

Keep these factors in mind to pick the best magnet for your environment and specific application needs. For more on applying magnets in motor technology, visit application of magnets for motor.

Industry Use Cases and Practical Examples

Electronics and Consumer Gadgets

Neodymium magnets are the go-to in small electronics like smartphones, headphones, and hard drives thanks to their strong magnetic pull in a compact size. SmCo magnets show up less frequently here but are preferred when heat resistance is needed, such as in specialized audio equipment.

Automotive Sector

Both Neodymium and SmCo magnets play big roles in automotive tech. NdFeB magnets power electric motors in hybrid and electric vehicles due to their high magnetic strength. SmCo magnets are often chosen for sensors and applications exposed to high temperatures under the hood where durability matters.

Aerospace and Defense

SmCo magnets shine in aerospace and defense because of their exceptional temperature stability and corrosion resistance. They can handle the harsh environments in jets and military gear where reliability is critical. Neodymium magnets are used too but often with added coatings or cooling to manage their temperature sensitivity.

Medical Devices

In medical tech, precision and reliability are key. Neodymium magnets are common in equipment like MRI machines and surgical tools, where powerful magnetic fields are needed in compact form. SmCo is also used in medical devices that must tolerate higher temperatures or corrosive conditions while maintaining magnetic performance.

Renewable Energy and Wind Turbines

Wind turbines require magnets that can handle heat and weather exposure over long periods. Here, SmCo magnets are favored due to their temperature resistance and durability. However, some wind turbine designs use neodymium magnets for higher efficiency, provided they are well-protected against corrosion.

Both magnet types have clear roles depending on the exact demands of the industry and environment they operate in.

Which Magnet Is Better Context Dependent Answer

Choosing between neodymium magnets and SmCo magnets really depends on your specific needs and environment. Each has strengths that make it better suited for certain situations.

When Neodymium Is Preferable

- High magnetic strength needed: Neodymium (NdFeB) magnets provide the strongest magnetic pull, making them ideal for compact devices or applications requiring maximum power.

- Cost-sensitive projects: They’re generally more affordable and widely available, which works well for consumer electronics and mass-produced items.

- Lower temperature environments: Perfect if your device won’t be exposed to extreme heat since NdFeB magnets lose strength above about 176°F (80°C).

- Applications needing versatility: Great for everything from headphones to electric motors.

When SmCo Is Preferable

- High temperature tolerance: SmCo magnets perform well at temperatures up to 572°F (300°C), making them reliable for harsh industrial and aerospace environments.

- Better corrosion resistance: They hold up well without extra coatings, so they’re ideal for outdoor or chemically aggressive settings.

- Long-term stability: SmCo magnets maintain performance over time even under stress or temperature swings.

- When brittleness is less of a concern: Suitable if mechanical strength isn’t the top priority since SmCo magnets can be more brittle.

Hybrid Use Cases or Alternatives

- Using both magnets: Some designs use neodymium for strength and SmCo for temperature resilience in different parts of one device.

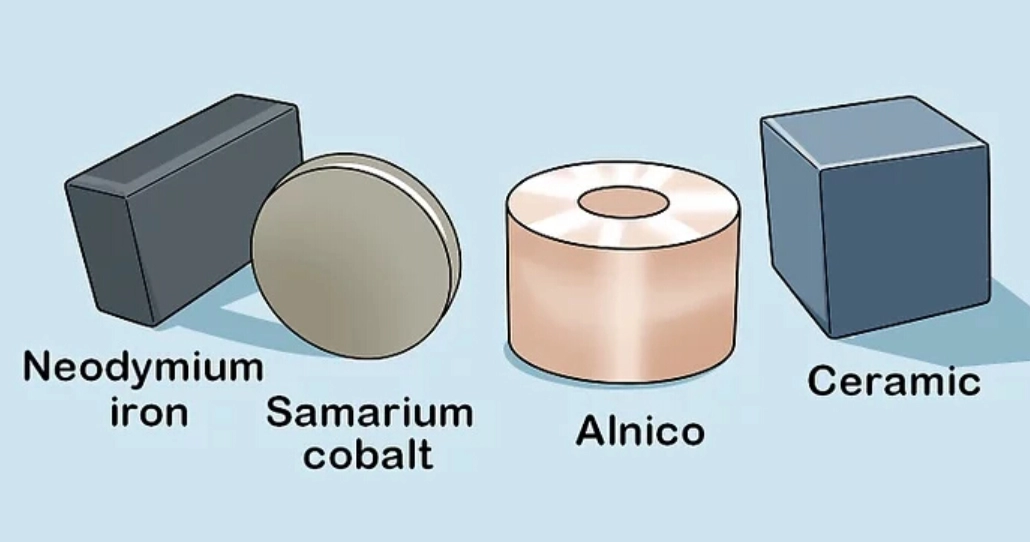

- Alternatives: Depending on requirements, other magnets like ferrite or Alnico might be a fit, especially when cost or corrosion is a big factor.

- Protective coatings: For either magnet type, coatings can improve durability and expand application options.

In short, neither magnet is better across all situations. Your choice depends on how you balance strength, temperature needs, corrosion resistance, and budget.

Why Choose NBAEM for Your Magnet Supply

When it comes to sourcing high-quality neodymium and SmCo magnets, NBAEM stands out for several reasons. Here’s why we’re a trusted choice in the United States market:

Product Quality and Customization Options

- Premium Materials: We use top-grade raw materials to ensure magnets deliver strong performance and durability.

- Custom Solutions: Whether you need specific shapes, sizes, or magnet grades, NBAEM offers full customization to meet your exact needs.

- Strict Quality Control: Every batch undergoes rigorous testing for magnetic strength, corrosion resistance, and mechanical properties.

Expertise in Both Neodymium and SmCo Materials

- Deep Knowledge: We understand the nuances between NdFeB and SmCo magnets, helping you pick the right magnet for your application.

- Technical Support: Our experts provide guidance on magnet selection, performance, and handling for both types.

Supply Chain Reliability and Competitive Pricing

- Consistent Availability: With a strong manufacturing base in China, we maintain steady stock levels to avoid delays.

- Cost-Effective: NBAEM offers competitive prices without compromising on quality, balancing price and performance perfectly.

- Flexible Order Sizes: We accommodate both small and bulk orders to suit your project scale.

Customer Service and Technical Support

- Responsive Team: Our customer service aligns with U.S. business hours, ensuring prompt responses.

- After-Sales Support: We are available to assist with installation tips, safe handling, and troubleshooting.

- Educational Resources: NBAEM provides clear information to help customers understand the differences between neodymium vs samarium cobalt magnets and their best uses.

Choosing NBAEM means getting magnets backed by quality, expertise, and reliable service, tailored for your applications in electronics, automotive, aerospace, and more.

FAQs About Neodymium vs SmCo Magnets

Can neodymium magnets replace SmCo in all applications?

Not always. Neodymium magnets are stronger and more affordable but don’t perform as well at high temperatures or in harsh, corrosive environments. SmCo magnets excel where temperature stability and corrosion resistance matter, like in aerospace or automotive parts exposed to heat. So, it depends on where and how you plan to use them.

How to handle magnets safely?

Both Neodymium and SmCo magnets are strong and can snap together quickly, risking finger injuries or damage. Always keep them apart slowly, use protective gloves if needed, and store magnets where they can’t attract metal objects or electronics. Also, keep them away from pacemakers and sensitive electronics.

What are the environmental impacts of these magnets?

Both use rare earth elements, whose mining can harm the environment. Neodymium mining has a bigger footprint but generally costs less, while SmCo involves cobalt, which raises ethical concerns due to mining conditions. Recycling and responsible sourcing are growing in importance to reduce environmental impact in the worldwide market and beyond.

[…] don’t expect. If you want to learn more about different magnet types and their uses, check out how neodymium magnets compare to SmCo magnets for a deeper dive into strong magnets for home […]