Comparison for samarium cobalt magnets(SmCo) and neodymium (NdFeB)

When comparing magnets like samarium cobalt magnets(SmCo) and neodymium magnets(NdFeB), understanding their strength starts with key technical measures. The main metric is maximum energy product (BHmax), which indicates how much magnetic energy a magnet can store. Higher BHmax means a stronger magnet for a given size.

Other important factors include:

- Coercivity: The resistance to demagnetization. Higher coercivity means the magnet holds its strength better under external magnetic fields or heat.

- Residual flux density (Br): The magnetic flux density the magnet produces in a zero external field. It reflects the magnet’s intrinsic strength.

- Temperature stability: How the magnet’s strength changes when exposed to elevated temperatures. Some magnets lose performance quicker when heated.

- Corrosion resistance: The magnet’s ability to withstand oxidation or environmental damage, impacting durability.

- Mechanical properties: Brittleness, hardness, and how magnets tolerate impacts or machining.

These key metrics help engineers and buyers determine which magnet suits specific applications. While BHmax gives a headline strength figure, factors like coercivity and temperature performance shape real-world reliability and effectiveness. Understanding these measures prepares us to dive deeper into how samarium cobalt magnets and neodymium magnets perform differently across conditions.

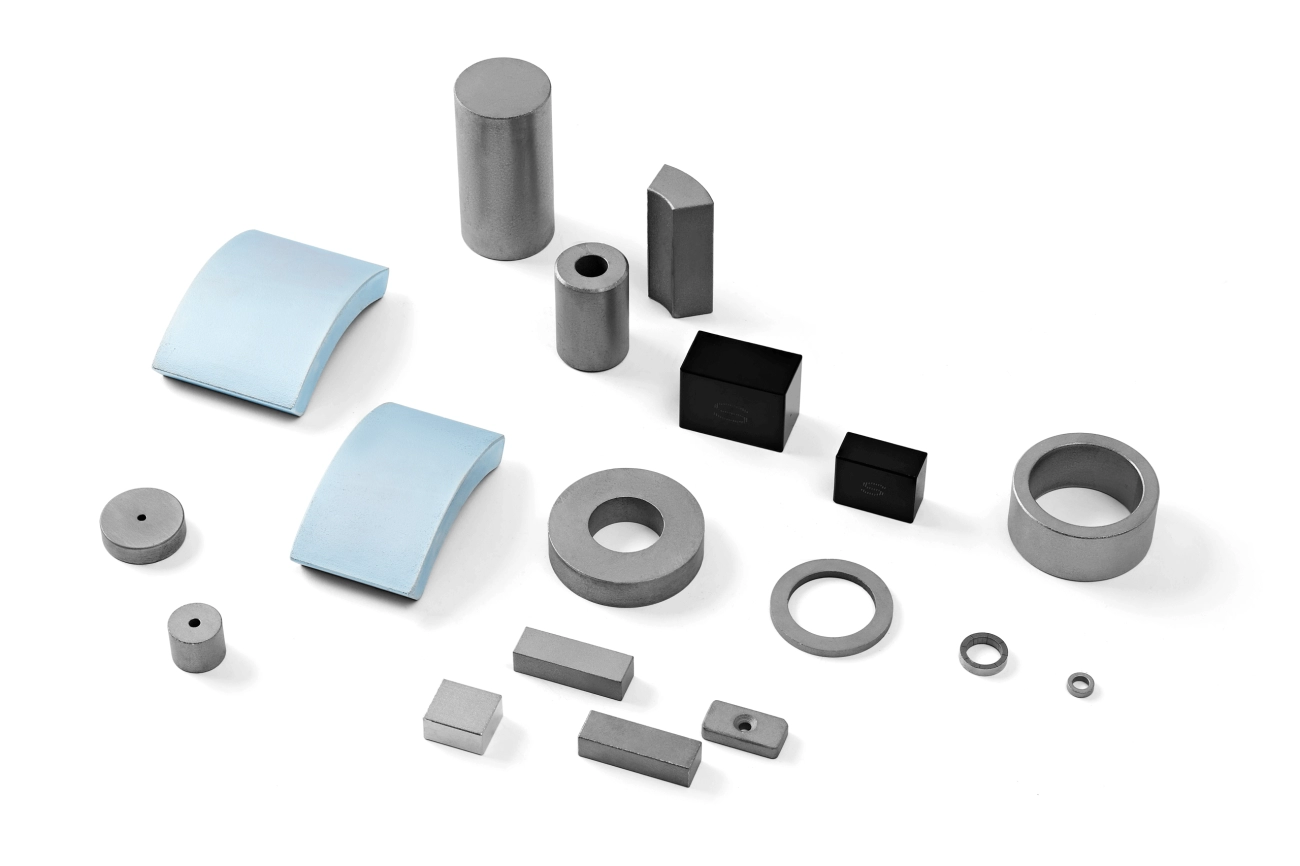

Samarium Cobalt Magnets SmCo Overview

Samarium cobalt magnets (SmCo) are a type of rare earth magnet known for their strong magnetic properties and excellent durability. They are made from an alloy of samarium, cobalt, and other elements, produced through a powder metallurgy process that involves pressing and sintering the ingredients into solid magnets.

In terms of magnetic strength, samarium cobalt magnets typically have a maximum energy product (BHmax) ranging from 16 to 30 MGOe, which is strong but generally lower than neodymium magnets. What sets SmCo apart is their exceptional thermal stability—they can operate reliably at temperatures up to 350°C (662°F) without losing much magnetism.

Samarium cobalt magnets also shine when it comes to resistance to corrosion and oxidation. Unlike neodymium magnets, they don’t require special coatings to prevent rust, making them ideal for harsh or outdoor environments. Mechanically, these magnets are brittle and can chip or crack if mishandled, so careful mounting and protection are important.

Key highlights of Samarium Cobalt magnets:

- Composition: Samarium, cobalt, and minor additional elements

- Manufacturing: Powder metallurgy, pressed and sintered

- Typical BHmax: 16–30 MGOe

- High temperature use: Up to 350°C

- Corrosion resistance: High, no coating needed

- Mechanical properties: Brittle, requires careful handling

SmCo magnets are perfect when you need good strength combined with stability in extreme temperatures and corrosive conditions.

Neodymium Magnets NdFeB Overview

Neodymium magnets, also called NdFeB magnets, are made mainly from neodymium, iron, and boron. They are known for having the highest magnetic strength among commercial rare earth magnets, often showing a maximum energy product (BHmax) significantly above samarium cobalt magnets. This makes NdFeB magnets the go-to choice when you need the strongest magnetic field in a compact size.

However, their high strength brings some trade-offs. NdFeB magnets have lower resistance to heat compared to samarium cobalt and can start losing magnetism when exposed to temperatures above about 80 to 150°C. They are also more prone to demagnetization if overheated or subjected to strong opposing magnetic fields.

Another factor is corrosion. Unlike SmCo magnets, neodymium magnets tend to oxidize easily and require protective coatings like nickel, zinc, or epoxy to prevent rust, especially in humid or outdoor environments.

Mechanically, NdFeB magnets are brittle and can chip or crack if handled roughly, so careful design and mounting are important in applications where mechanical stress is expected.

For more detailed information on how neodymium magnets compare to other types, check out our neodymium magnets vs ceramic magnets article.

Direct Strength Comparison Are Samarium Cobalt Magnets Stronger

When comparing samarium cobalt magnets and neodymium magnets, the main measure of strength is the maximum energy product, or BHmax. This tells us how much magnetic energy the magnet can store and deliver.

| Magnet Type | Typical BHmax (MGOe) | Coercivity (Resistance to Demagnetization) | Temperature Stability |

|---|---|---|---|

| Samarium Cobalt Magnets | 20 – 30 | Very High | Stable up to 300°C or more |

| Neodymium (NdFeB)Magnets | 30 – 52 | High (but lower than SmCo in heat) | Stable up to 80-150°C |

Neodymium magnets often have a higher BHmax, meaning they’re generally stronger in terms of raw magnetic force. But samarium cobalt (SmCo) magnets hold an edge in resistance to demagnetization (coercivity), especially at higher temperatures.

Coercivity and Demagnetization

- SmCo magnets maintain coercivity better when heated.

- NdFeB magnets can lose magnetism faster when exposed to heat or strong magnetic fields.

Stability at Elevated Temperatures

- SmCo magnets keep their magnetic strength at temperatures up to 300°C.

- NdFeB begins to weaken at temperatures above 80-150°C, depending on grade and coatings.

Real World Performance

- SmCo is preferred in applications like aerospace, military, and high-temperature motors where heat and corrosion resistance matter more than sheer strength.

- NdFeB wins when maximum magnetic strength is the priority, such as in consumer electronics or compact motors operating in moderate temperature environments.

In short, samarium cobalt magnets aren’t generally stronger than neodymium magnets in raw power, but they outperform NdFeB magnets in heat resistance and long-term stability under harsh conditions.

Other Factors Influencing Magnet Choice

When picking between samarium cobalt (SmCo) and neodymium (NdFeB) magnets, strength isn’t the only thing to consider. Here are some key factors that often influence the decision:

Cost and Availability

- Neodymium magnets tend to be more affordable and widely available, making them popular for large-scale production.

- Samarium cobalt magnets are pricier due to rare materials and complex manufacturing but offer specialty benefits.

Environmental Conditions

- Samarium cobalt magnets shine in harsh environments—they resist corrosion and handle high temperatures up to 300°C without losing magnetic power.

- NdFeB magnets perform best in moderate temperatures but need protective coatings since they corrode easily and weaken above 80-150°C.

Application Needs

- For motors, sensors, medical devices, and aerospace parts, the magnet’s operating environment and stability matter.

- SmCo is ideal where long-term stability and heat resistance are critical, such as aerospace or high-temp sensors.

- NdFeB suits applications demanding maximum magnetic strength at a lower cost, like electric motors or consumer electronics.

Longevity and Reliability

- Samarium cobalt magnets maintain magnetic strength and physical integrity longer in extreme conditions.

- NdFeB magnets can degrade over time if exposed to heat or moisture without proper coatings or designs.

These factors affect your choice just as much as raw magnetic strength. Considering how and where your magnet will be used helps ensure you get the best performance over time. For detailed insights into specific applications, you can check out NBAEM’s guide on different magnet types and uses.

When to Choose Samarium Cobalt Magnets Over Neodymium

Samarium cobalt (SmCo) magnets really shine in specific situations where neodymium (NdFeB) magnets fall short. Here’s when you should pick SmCo over NdFeB:

-

High temperature use above 150°C

SmCo magnets maintain strong magnetic performance at temperatures where NdFeB magnets begin to weaken or demagnetize.

-

Superior corrosion resistance without coatings

Unlike neodymium magnets, which need protective coatings to prevent rust, SmCo magnets naturally resist corrosion and oxidation, making them ideal for harsh or humid environments.

-

Long-term dimensional and magnetic stability

SmCo magnets hold their shape and magnetic strength over time better than NdFeB, especially under thermal cycling or stressful conditions.

Use Cases from NBAEM’s Portfolio

- Aerospace components exposed to extreme heat

- Motors and generators operating in hot environments

- Sensors in corrosive or outdoor settings without needing extra coatings

- Durable medical devices requiring stable magnetic fields over a long lifespan

Choosing samarium cobalt makes sense when you need reliable magnets ready to perform in tough conditions without extra maintenance or risk of failure.

When to Choose Neodymium Over Samarium Cobalt

Neodymium magnets (NdFeB) stand out when you need maximum magnetic strength at moderate temperatures—typically below 150°C. If your project demands the strongest fields for compact parts or lightweight designs, NdFeB is usually the go-to choice.

Here are key reasons to pick neodymium over samarium cobalt:

-

Higher Magnetic Power

NdFeB magnets generally have a higher maximum energy product (BHmax) than SmCo, which means stronger magnetic force in smaller sizes.

-

Cost Effectiveness

Neodymium magnets are more affordable than samarium cobalt, making them ideal for budget-conscious projects or large-scale production runs.

-

Shaping and Coatings

NdFeB magnets can be easily shaped and coated (like with nickel or epoxy) to improve corrosion resistance. This flexibility is great for mass production and custom parts.

-

Volume Manufacturing

Their lower cost and versatility make neodymium magnets a popular choice for industries needing large quantities—like automotive motors, consumer electronics, and sensors.

NBAEM Customer Success Examples

-

Electric Vehicle Motors

NdFeB magnets provide the necessary power density for high-performance motors at a reasonable cost.

-

Speaker and Audio Equipment

Customers rely on NdFeB for compact, strong magnets that improve sound quality without bulk.

-

Industrial Sensors

Larger orders with customized shapes benefit from NdFeB’s ease of coating and machining.

If your application runs in typical temperature ranges and demands the highest magnetic strength with cost efficiency, neodymium magnets from NBAEM are a smart pick.

and Recommendation

When it comes to strength, neodymium (NdFeB) magnets usually take the lead with higher magnetic power. However, they tend to lose stability under extreme heat and harsh conditions. On the other hand, samarium cobalt (SmCo) magnets offer excellent strength in challenging environments, maintaining their magnetic properties well even at high temperatures and resisting corrosion without needing extra coatings.

Choosing the right magnet depends on your specific needs:

- Go with NdFeB magnets if your priority is maximum magnetic strength at moderate temperatures and cost-efficiency, especially for high-volume production.

- Choose SmCo magnets if your application involves high temperatures (above 150°C), exposure to corrosive environments, or requires long-term magnetic and dimensional stability.

For professional guidance tailored to your project and access to top-quality magnets, contact NBAEM’s experts. They can help you decide which magnet type will work best for your unique requirements and ensure you get reliable, high-performance materials.

Explore more about magnet uses and types on NBAEM to make the most informed choice for your application.

FAQs About Samarium Cobalt and Neodymium Magnets

Are samarium cobalt magnets suitable for mass production

Yes, samarium cobalt (SmCo) magnets can be mass-produced, but they’re generally more expensive and brittle compared to neodymium magnets. Their manufacturing requires careful handling because of their fragility, making production slower and costlier. For high-volume projects where cost is a concern, NdFeB magnets often make more sense.

Can neodymium magnets withstand heat better now with new coatings

New coatings and protective layers have improved neodymium (NdFeB) magnets’ resistance to corrosion, but their core temperature limits haven’t changed much. While coatings help protect from rust and minor heat exposure, NdFeB magnets still perform best under moderate temperatures (typically under 150°C). For higher heat, samarium cobalt remains the better choice.

What are the lifespan differences

SmCo magnets usually last longer in harsh conditions because of their superior thermal stability and corrosion resistance. NdFeB magnets can degrade faster when exposed to heat, moisture, or corrosive environments unless well-coated. With proper care, both types can last for years, but SmCo magnets generally offer more consistent long-term performance.

How do NdFeB and SmCo compare in magnetic field consistency

Samarium cobalt magnets maintain more stable magnetic fields over a wider temperature range and resist demagnetization better than neodymium magnets. NdFeB magnets have stronger initial magnetic fields but can lose strength faster if exposed to heat or physical stress. In applications demanding consistent magnetic performance, SmCo is often preferred.

Leave A Comment