Understanding UAV Motors Basics and Terminology

When choosing a motor for your UAV, it helps to know the basics of the two main types: brushed and brushless motors. Both are electric motors but differ in design and how they create motion.

What are Brushed and Brushless Motors?

- Brushed motors use brushes and a commutator to deliver electric current to the spinning part (rotor). The brushes physically contact the rotor, switching the current on and off to keep the motor turning.

- Brushless motors don’t have brushes. Instead, they use electronic controllers to switch current through coils in the stator around a permanent magnet rotor, making them more efficient and longer-lasting.

How Each Motor Works

- In brushed motors, the brushes and commutator mechanically switch the current, which causes the rotor to spin.

- In brushless motors, electronic controllers handle current switching, driving the motor more smoothly with less wear and tear.

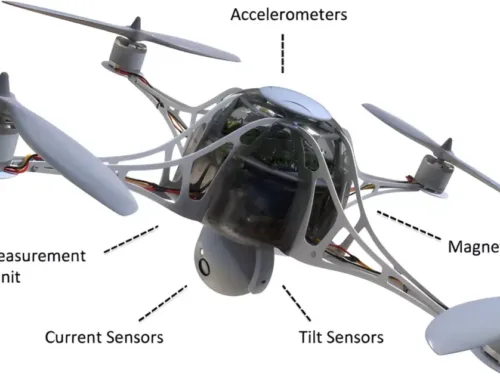

Typical UAV Applications

- Brushed motors are found mostly in smaller, entry-level, and hobby drones because they’re simple, cheaper, and easy to control.

- Brushless motors dominate in commercial, racing, and professional UAVs where efficiency, durability, and power are key.

Understanding these basics helps you decide which motor type matches your UAV’s needs, whether it’s a lightweight hobby drone or a high-performance commercial flyer.

Brushed Motors Features Benefits and Limitations

Brushed motors are the simpler type of UAV motor. Inside, they have brushes and a commutator that physically switch the current to spin the motor. This design makes them easy to understand and control without fancy electronics.

Pros of Brushed Motors

- Simple design means low initial cost

- Easy to control with basic speed controllers

- Good for beginners and small DIY drones

- Affordable and quickly replaceable parts

Cons of Brushed Motors

- Brushes wear out over time, requiring regular maintenance

- Generally less efficient than brushless motors

- Shorter lifespan due to brush friction

- Tend to run hotter and waste more energy

Common UAV Uses

Brushed motors fit well in small, budget-friendly drones or toys where performance isn’t critical. You can expect solid performance for casual flights but limited flight time and power compared to brushless motors. For lightweight flying and simple applications, they do the job without breaking the bank.

| Feature | Brushed Motor Characteristics |

|---|---|

| Structure | Brushes + commutator inside |

| Cost | Low upfront cost |

| Control | Simple, minimal electronics |

| Maintenance | Needs brush replacement regularly |

| Efficiency | Moderate to low |

| Lifespan | Shorter due to wear |

| Typical UAV Use | Small hobby drones, budget models |

Brushless Motors Features Benefits and Limitations

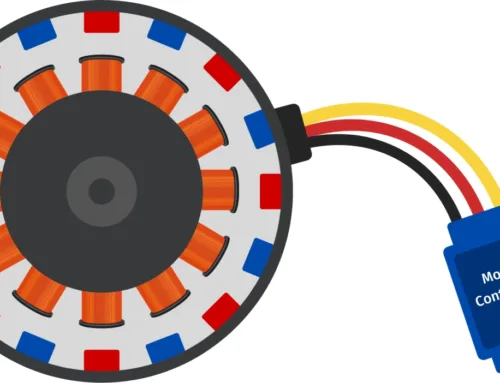

Brushless motors are built differently from brushed ones. Instead of brushes making contact to transfer current, brushless motors use electronic controllers to manage power flow. The rotor contains permanent magnets, while the stator has coils energized in a sequence to generate motion. This design means there’s no physical friction from brushes, making the motor more efficient and durable.

Benefits of Brushless Motors

- Higher efficiency: Less energy wasted, so longer flight times for your UAV.

- Greater durability: No brushes to wear out, resulting in a longer motor lifespan.

- Lower maintenance: Fewer moving parts means less upkeep.

- Better power-to-weight ratio: More power without extra bulk, perfect for UAVs needing agility and payload capacity.

Limitations of Brushless Motors

- Higher upfront cost: Initial price is noticeably higher than brushed motors.

- Complex control electronics: Requires electronic speed controllers (ESCs), adding complexity and cost.

Why Brushless Motors Dominate Commercial and High-End UAVs

Commercial drones and professional UAVs prioritize performance and reliability. The brushless motor’s efficiency, durability, and power-to-weight benefits translate into longer flights, better speed, and higher payload capabilities. This makes them the go-to choice for serious drone operators who need consistent, high-quality performance.

Key Factors to Consider When Choosing Between Brushed and Brushless Motors for Your UAV

When deciding between brushed vs brushless motors for your UAV, it’s important to weigh several key factors that affect performance and usability.

Power output and efficiency

Brushless motors generally deliver higher power and better efficiency thanks to their design, which means longer flight times and stronger thrust. Brushed motors, while simpler, tend to waste more energy and generate more heat, limiting performance.

Maintenance and durability

Brushed motors require regular upkeep because brushes wear out over time, leading to shorter lifespan and more downtime. Brushless motors, on the other hand, have no brushes to wear, making them more durable and requiring less maintenance in the long run.

Weight and size constraints

Brushless motors tend to be lighter and more compact for the same power level, crucial for UAV designs where every ounce counts. Brushed motors are often bulkier and heavier, which can reduce flight time and agility.

Cost considerations

Brushed motors are lower cost upfront, which can be appealing for hobbyists or budget builds. Brushless motors come with a higher price tag, but their efficiency and lifespan typically make them a better investment for serious users.

Control complexity and electronics requirements

Brushed motors are easier to control with simple ESCs (Electronic Speed Controllers), making them beginner-friendly. Brushless motors require more advanced ESCs and controllers, which can be more complex but offer better precision and performance.

Flight duration and mission profile

For short, casual flights, brushed motors might suffice. But if your UAV mission involves long flights, heavy payloads, or professional-grade applications, brushless motors are the clear winner due to their power and efficiency benefits.

Compatibility with UAV frame and application needs

Before choosing, ensure your motor fits well with your UAV frame size, weight limits, and the specific tasks you want your drone to perform. Brushless motors often better match commercial and industrial UAV frames, while brushed motors suit smaller, lightweight hobby drones.

By considering these points, you’ll find the right balance between cost, performance, and reliability for your UAV build.

Performance Comparison Brushed vs Brushless in Real World UAV Scenarios

When we look at how brushed and brushless motors perform in actual UAV flights, the differences become clear. Here’s a quick rundown comparing key factors like efficiency, thrust, runtime, and their effects on flight.

| Feature | Brushed Motors | Brushless Motors |

|---|---|---|

| Efficiency | Lower efficiency, more energy loss | Higher efficiency, better power use |

| Thrust | Moderate thrust, less responsive | Stronger thrust, quicker response |

| Runtime | Shorter flight times | Longer flights due to less power waste |

| Flight Stability | Less consistent due to brush friction | Smoother, more stable control |

| Speed | Limited max speed | Higher top speeds achievable |

| Payload Capacity | Reduced lift capability | Supports heavier payloads effectively |

| Battery Consumption | Higher due to inefficiencies | Lower, extends battery life |

| Thermal Management | Tends to heat up faster, risk wear | Better heat dissipation, lasts longer |

Real World Impact

- Flight Duration: Brushless motors consistently outlast brushed ones, making them ideal for missions requiring longer airtime.

- Stability and Control: The smoother operation of brushless motors improves flight stability, which helps in tasks like aerial photography or inspections.

- Payload and Speed: If your UAV needs to carry heavier cameras or equipment, brushless motors handle the extra weight without sacrificing speed.

- Battery Life: Because brushless motors use power more efficiently, you get better battery runtime, which is a big deal for anyone flying in the U.S. who wants to maximize flight time without frequent recharges.

- Thermal Issues: Brushed motors heat up faster, which can limit performance and lifespan, especially in hot climates common across many U.S. regions.

In short, brushless motors offer better performance across the board in practical UAV scenarios, which explains why they dominate commercial and professional drone markets in the States. Yet, brushed motors still find their place in simpler, budget-friendly setups or smaller hobby drones where cost and ease of use matter more than top-end performance.

How NBAEMs Magnetic Materials Enhance Brushless UAV Motor Performance

NBAEMs, a leading supplier of high-quality magnetic materials, plays a key role in advancing brushless motor technology for UAVs. Their specialized magnets are designed to boost both power and efficiency in drone motors, making a real difference in flight performance.

Brushless motors rely heavily on strong, reliable magnets to generate the magnetic fields that drive the rotor. NBAEMs magnets offer:

- High magnetic strength which translates to increased power density—more thrust without adding weight.

- Better thermal resistance helping motors stay cool during long flights or heavy loads, improving reliability.

- Improved efficiency meaning lower power consumption and longer battery life for drones.

Thanks to NBAEMs’ cutting-edge magnetic materials, manufacturers can build brushless UAV motors that perform better under demanding conditions, last longer, and offer greater payload capacity. This is why NBAEMs magnets have become a cornerstone in the evolution of high-performance UAV motors, especially in the US market where efficiency and durability are top priorities.

Practical Recommendations Choosing the Right Motor for Your UAV Use Case

When picking between brushed vs brushless motors for your UAV, it really comes down to what you need from your drone.

Hobbyist Small UAVs – When Brushed Motors Might Work

If you’re just flying small drones for fun or learning the ropes, brushed motors can be a solid choice. Here’s why:

- Lower upfront cost – great if you’re budget-conscious.

- Simpler control systems – easier to get started without fancy electronics.

- Adequate performance for light tasks – indoor flying or short flights.

Keep in mind, brushed motors need more maintenance and won’t last as long, so they’re best if your missions are casual and short-lived.

Professional Commercial UAVs – Why Brushless Motors Make Sense

For serious UAV users—like pros in surveying, agriculture, or delivery—brushless motors usually pay off:

- Higher efficiency means longer flight times and better battery life.

- More power and smoother performance help with heavier payloads and faster speeds.

- Lower maintenance cuts downtime and repair costs.

- Better durability suits demanding or extended missions.

If your work means reliability and top performance, investing in brushless motors is almost always worth it.

Step by Step Guide to Choosing Based on Your UAV Mission

- Define your mission profile:

- Short, casual flights → consider brushed motors.

- Long, demanding flights → brushless is likely better.

- Evaluate weight and payload needs:

- Light frames and small payloads can get by with brushed motors.

- Heavier or commercial-grade UAVs benefit from brushless efficiency.

- Check budget and maintenance capacity:

- Tight budget and willingness to maintain → brushed.

- Bigger budget and desire for long-term reliability → brushless.

- Consider control system complexity:

- Simple controllers work with brushed motors.

- Brushless motors need electronic speed controllers (ESC), so plan accordingly.

- Assess flight duration requirements:

- If you want longer flight times and better thermal management, brushless motors are the answer.

By balancing these factors, you’ll find the right motor for your UAV that fits your American drone flying habits—whether you’re out for weekend fun or tackling professional aerial projects.

Future Trends in UAV Motor Technology

The UAV motor world is evolving fast, with new technologies and materials shaping the future of drone performance. One big area to watch is advancements in magnetic materials, especially those from NBAEMs. These next-gen magnets boost brushless motor efficiency, power density, and thermal resistance—key factors that keep UAVs flying longer and handling tougher conditions.

Brushless motors are becoming the standard as their control electronics get smarter and more affordable. We’re seeing greater integration of brushless motors across all types of UAVs, from hobby drones to heavy-duty commercial models. This shift is thanks to their superior power output, durability, and lower maintenance needs.

NBAEMs is playing a crucial role in supporting the UAV industry by innovating magnetic materials that help manufacturers build motors with improved performance and reliability. Their commitment helps push the boundaries of what’s possible—making UAVs lighter, stronger, and more efficient.

Expect to see these magnetic improvements combined with smarter motor designs and electronic controls, creating UAVs that fly farther, carry more, and operate more smoothly in the coming years.

Leave A Comment