Can magnets rust? The short answer is yes—some magnets can corrode over time, and it can seriously impact their strength and lifespan. Whether you’re using neodymium magnets in DIY projects or industrial magnets in machinery, knowing how and why rust happens is key to protecting your investment. In this post, you’ll learn exactly which types of magnets are prone to rust, what causes it, and the smartest ways to prevent magnet corrosion before it damages performance. Let’s get right into it.

What is Rust and Understanding Corrosion

Rust is a common form of corrosion that happens when iron or iron-based metals react with oxygen and moisture. The process, called oxidation, creates a reddish-brown flaky substance known as iron oxide. While rust is specific to iron, magnets made with iron or steel components can be affected by similar corrosion processes.

Types of Corrosion That Can Affect Magnets

Magnets can face multiple forms of surface damage depending on their material and environment:

- Rust (Iron Oxide): Occurs in magnets with iron content, such as neodymium or ferrite types.

- Tarnish: A thin surface layer that changes color but doesn’t significantly weaken the structure; more common in some metal coatings.

- General Corrosion: Broader metal degradation that can weaken both the structure and magnetic performance.

Environmental Factors That Promote Corrosion

Corrosion needs certain conditions to start and spread. The most common factors include:

| Factor | Effect on Corrosion |

|---|---|

| Moisture | Speeds up oxidation by providing water for the reaction. |

| Oxygen | Combines with iron atoms to form rust. |

| Salts | Saltwater environments, like coastal areas, dramatically increase corrosion speed by enhancing water conductivity. |

| Chemicals | Acids or industrial vapors can attack magnet coatings and expose iron. |

In short, corrosion happens when the material, the environment, and the presence of electrolytes like salts work together to break down metal surfaces — something that can affect magnets if they’re not properly protected.

Types of Magnets and Their Susceptibility to Rust

Not all magnets rust the same way. The main factor is whether the magnet’s material contains iron or iron-based alloys, since iron is what oxidizes and causes rust. Here’s a quick rundown of common magnet types and how they stand up to corrosion:

Ferrite (Ceramic) Magnets

- Made mostly from iron oxide mixed with ceramic material

- Can withstand moisture better than pure metal magnets, but still contain iron and may corrode over long exposure to water or salt

Neodymium (NdFeB) Magnets

- Extremely strong but high in iron content

- Very prone to rust if left uncoated or if the coating is damaged

- Often plated with nickel, zinc, or epoxy to protect them

Alnico Magnets

- Made from aluminum, nickel, and cobalt, with some iron content

- More corrosion-resistant than neodymium, but still not immune in harsh environments

Samarium Cobalt Magnets

- Low iron content, very resistant to corrosion

- Can be used without coating in most environments

Common Protective Coatings for Magnets

- Nickel plating: Gives a shiny finish and good rust protection

- Epoxy coating: Great for outdoor, marine, or humid applications

- Zinc coating: Inexpensive protection, but wears faster than nickel

- Plastic or rubber coating: Adds impact resistance along with rust prevention

In short, magnets with high iron content like ferrite and neodymium need reliable coatings to avoid rust, while samarium cobalt and some alnico magnets can handle tough conditions better without extra protection.

Why Do Magnets Rust

Magnets rust for the same reason any iron-based material does — they contain iron that reacts with oxygen and moisture in the air. When this happens, iron oxide (rust) forms on the surface. Not all magnets have the same makeup, but types like neodymium (NdFeB) and ferrite have enough iron in them to make them prone to corrosion if left unprotected.

Environmental conditions play a big role. High humidity, water exposure, saltwater, and acidic environments speed up rust formation. Saltwater is especially harsh since salt acts as an electrolyte, making it easier for oxidation to happen. Even short exposure in damp or coastal areas can cause visible changes in unprotected magnets.

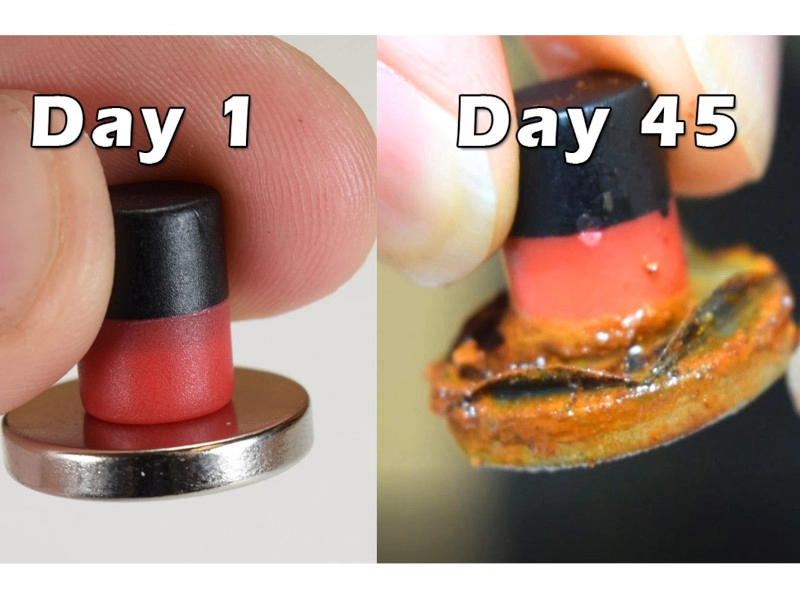

Most magnets meant for regular use are coated with materials like nickel, zinc, epoxy, or plastic to block moisture and oxygen. These coatings work well, but once they chip, crack, or wear down, the exposed areas will start to rust quickly. This is why damaged magnet surfaces should be repaired or replaced before corrosion spreads and weakens the magnet.

Signs Your Magnet is Rusting or Corroding

It’s pretty easy to spot when a magnet is starting to rust if you know what to look for. Here are some common signs:

Visual clues:

- Discoloration – Rust often shows up as reddish-brown spots, but it can also appear yellow, orange, or dark brown.

- Flaking or peeling – The surface may start chipping away, especially if a protective coating is damaged.

- Rough texture – Corrosion can eat into the metal, leaving it pitted or uneven.

Performance changes:

- Weakened pull – Rust can damage the magnet’s surface area, reducing its holding strength.

- Brittle structure – Severe corrosion can cause magnets, especially neodymium ones, to crack or break apart.

How to inspect for early corrosion:

- Keep magnets clean and dry so changes are obvious.

- Check regularly for any coating scratches or chips—these are common entry points for moisture.

- Pay extra attention to magnets stored or used outdoors, near water, or in damp conditions.

Catching these issues early can save you from full magnet failure, especially if you depend on them in tools, equipment, or industrial setups.

Does Rust Affect Magnet Performance

Rust can absolutely harm a magnet’s performance. When corrosion sets in, it doesn’t just change the way the magnet looks—it eats into the material itself. For magnets with iron content, rust expands as it forms, which can cause surface pitting, cracking, or flaking. Over time, the magnet can lose mass and structural strength.

The magnetic field itself can weaken if rust damages enough of the magnet’s surface area or causes parts to break off. Adhesion also suffers—especially with flat or disc magnets—because a rough, corroded surface doesn’t grip metal contact points as well.

You’ll usually notice serious performance loss when:

- The magnet’s coating is badly worn or peeling.

- There’s visible deep rust or chunking of material.

- The magnet starts chipping apart with light pressure.

Once corrosion gets to that stage, cleaning won’t restore the magnet’s original strength. In most cases, replacement is the safer and more effective option, especially in applications where reliability matters—like machinery, tools, or holding fixtures.

How to Prevent Magnets from Rusting

Keeping magnets in good shape isn’t hard if you know what to watch out for. Rust happens when moisture, oxygen, and iron meet — so the goal is to limit exposure to those elements. Here’s what works:

Store in the Right Environment

- Keep them dry – A clean, low-humidity place is best.

- Avoid temperature swings – Sudden changes can cause condensation, which speeds up corrosion.

- Use sealed containers or bags for long-term storage, especially near water.

Choose the Right Coating

For magnets used in harsher spots like outdoors or near water:

- Go for coated magnets – Nickel, epoxy, zinc, or plastic coatings help block moisture.

- NBAEM offers custom sealing and coating options so magnets can handle marine, chemical, or industrial conditions.

Cleaning and Maintenance

- Wipe magnets with a soft, dry cloth before storing.

- If dirt or grease builds up, use mild soap and water, then dry right away.

- Never use harsh acids or strong alkalis — they can strip protective coatings.

Avoid High-Risk Contact

- Skip prolonged exposure to water, saltwater, chemicals, and acids.

- In workshops or garages, keep magnets away from corrosive cleaners or metal shavings that trap moisture.

Pro Tips from NBAEM

- Handle magnets carefully to avoid chips or cracks in the coating. Even a small break can let rust creep in.

- For industrial use, plan regular inspections and replace damaged magnets before they cause bigger problems.

How to Remove Rust from Magnets

If a magnet starts showing rust, you can sometimes clean it and keep using it—other times, it’s better to replace it. The trick is to clean without damaging the magnet’s coating or shape, since both affect performance.

Safe Rust Removal Methods:

- Light surface rust: Use a soft cloth with a mix of mild dish soap and warm water. Dry immediately to avoid more corrosion.

- Stubborn rust: A gentle scrub with a nylon brush or fine steel wool can work, but be careful not to scratch protective coatings, especially on neodymium magnets.

- Coated magnets: Avoid harsh abrasives and chemicals that can strip the nickel, epoxy, or zinc layer.

Things to Avoid:

- Strong acids like vinegar for uncoated magnets (they can make rust worse if they get into cracks).

- Power tools for cleaning—heat buildup can weaken the magnet’s strength.

When to Replace a Magnet:

- If rust has eaten deep into the material, causing pitting or crumbling.

- If the magnet has lost significant pull strength.

- If the coating is flaking off with exposed metal underneath.

For more details on choosing rust-resistant materials, you can check out this overview for types of magnets to compare options better suited for your environment.

Special Considerations for Industrial and Commercial Use

In industrial and commercial settings, rust on magnets isn’t just a cosmetic issue—it can cause serious equipment downtime and costly repairs. In factories, magnets are often exposed to humidity, oils, coolants, and even saltwater in marine applications. Any corrosion on the magnet’s surface can weaken its pull strength, damage surrounding machinery, and compromise safety.

For operations like manufacturing lines, conveyor systems, magnetic separators, or lifting equipment, using magnets with proper corrosion protection is essential. Nickel-plated neodymium, epoxy-coated magnets, or fully sealed assemblies are common choices to handle harsh conditions and extend lifespan.

NBAEM offers custom magnet solutions tailored for these environments—this includes high-grade coatings, stainless steel housings, and special alloys that resist rust without sacrificing magnetic strength. For example:

- Food processing plants use stainless-encased magnets to meet hygiene standards and prevent contamination.

- Mining operations rely on epoxy-coated magnets to withstand moisture, dust, and abrasive materials.

- Marine applications choose heavy-duty sealed magnets to handle saltwater exposure.

By choosing the right magnet type and protective finish up front, U.S. industries can reduce maintenance costs, avoid production stops, and keep critical systems running smoothly.

[…] or collect tiny iron particles, are exposed to moisture, or have coatings that break down and cause discoloration. When those magnets are pressed against stainless steel, they can leave behind that contamination […]