If you’ve ever wondered what is an Eddy current magnet and why it matters in today’s cutting-edge industries, you’re in the right place. This powerful device leverages Eddy currents—those swirling electrical currents in conductors—to create magnetic effects without physical contact. Understanding how these magnets work can unlock new possibilities in applications like braking systems, nondestructive testing, and material sorting. In this guide, we’ll break down the core principles behind Eddy current magnets and show why they’re essential tools in modern technology. Ready to explore? Let’s get started!

Understanding Eddy Currents

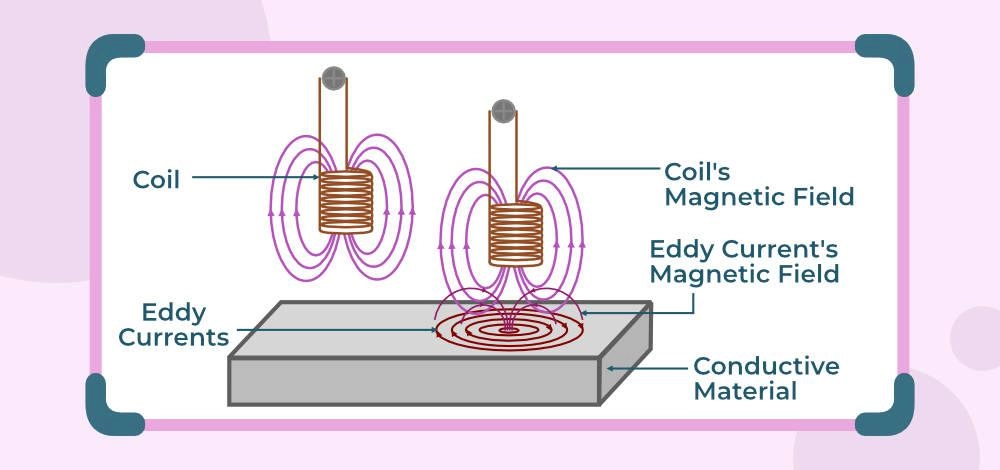

Eddy currents are loops of electrical current induced within conductors when they experience a changing magnetic field. This phenomenon is rooted in the physical principles of electromagnetic induction, first described by Faraday’s Law of Induction. Essentially, when a conductor moves through a magnetic field or when the magnetic field around it varies, an electric current is generated inside the material, flowing in circular paths called eddy currents.

These currents flow perpendicular to the magnetic field and are confined to the conductor’s surface or near the area where the magnetic flux changes most rapidly. The generation of eddy currents depends on factors such as the strength and frequency of the magnetic field, the electrical conductivity of the material, and its thickness.

Eddy currents have two major effects on conductive materials:

- Heating: As these currents flow through the resistance of the conductor, they generate heat. This is often used intentionally in induction heating applications, but in some settings, it results in energy loss.

- Opposing Magnetic Fields: According to Lenz’s Law, the induced eddy currents create their own magnetic fields that oppose the original magnetic field causing them. This can lead to magnetic damping and loss of energy in transformers, motors, and generators.

Understanding these principles is essential for designing devices like eddy current magnets, sensors, and braking systems, where controlling the behavior of these currents is critical.

What is an Eddy Current Magnet

An Eddy Current Magnet is a device that uses eddy currents—loops of electrical current induced in conductors—to produce magnetic effects without direct contact. Unlike traditional permanent magnets, which have a fixed magnetic field, or electromagnets, which rely on coils carrying current to generate magnetism, eddy current magnets work by inducing currents in conductive materials to create opposing magnetic fields.

These magnets consist mainly of a conductive material, such as copper or aluminum, and a magnetic source like a coil or permanent magnet that moves relative to the conductor. When the magnetic field changes near the conductor, eddy currents form inside it, generating their own magnetic field. This interaction creates forces used in applications like braking and sensing.

In , eddy current magnets differ by relying on induced currents and the interaction between those currents and magnetic fields, rather than relying solely on static or direct electric currents like other magnets. Their design typically includes:

- A magnetic field source (coil or permanent magnet)

- A conductive conductor (metal plate or disc)

- A structure to position and support these components for controlled magnetic interaction

Working Principle of Eddy Current Magnets

Eddy current magnets work by using the magnetic fields generated through Eddy currents in conductive materials. When a changing magnetic field passes through a conductor, such as aluminum or copper, it induces circular electric currents called Eddy currents. These currents create their own magnetic fields that oppose the original magnetic field, based on Lenz’s Law.

Here’s how it plays out:

- A magnet or electromagnet produces a changing magnetic field.

- This changing field induces Eddy currents in nearby conductive materials.

- The Eddy currents generate secondary magnetic fields that resist the movement or change causing them.

- This interaction produces a magnetic effect, such as force or braking.

The key players are:

- Magnetic fields: Provide the changing environment that induces currents.

- Conductors: Materials where Eddy currents flow; they need to be good electrical conductors.

- Magnetic materials: Often used to focus and enhance the magnetic flux.

This principle allows Eddy current magnets to work without physical contact. They create magnetic forces through induced currents, enabling smooth and adjustable operation in various applications. The interaction between the magnetic field and conductors is crucial, making material choice and magnetic design essential for effectiveness.

For more insights on how different magnets work, check out our resource on what are magnets attracted to.

Applications of Eddy Current Magnets

Eddy current magnets play a big role across various industries thanks to their unique ability to create magnetic effects without physical contact. Here’s where you’ll commonly find them:

-

Metal Detection

These magnets help identify metal objects quickly and reliably, widely used in security screening and recycling plants.

-

Braking Systems

Eddy current brakes are common in trains, roller coasters, and industrial machines. They provide smooth, wear-free deceleration by generating opposing magnetic fields without touching the moving parts.

-

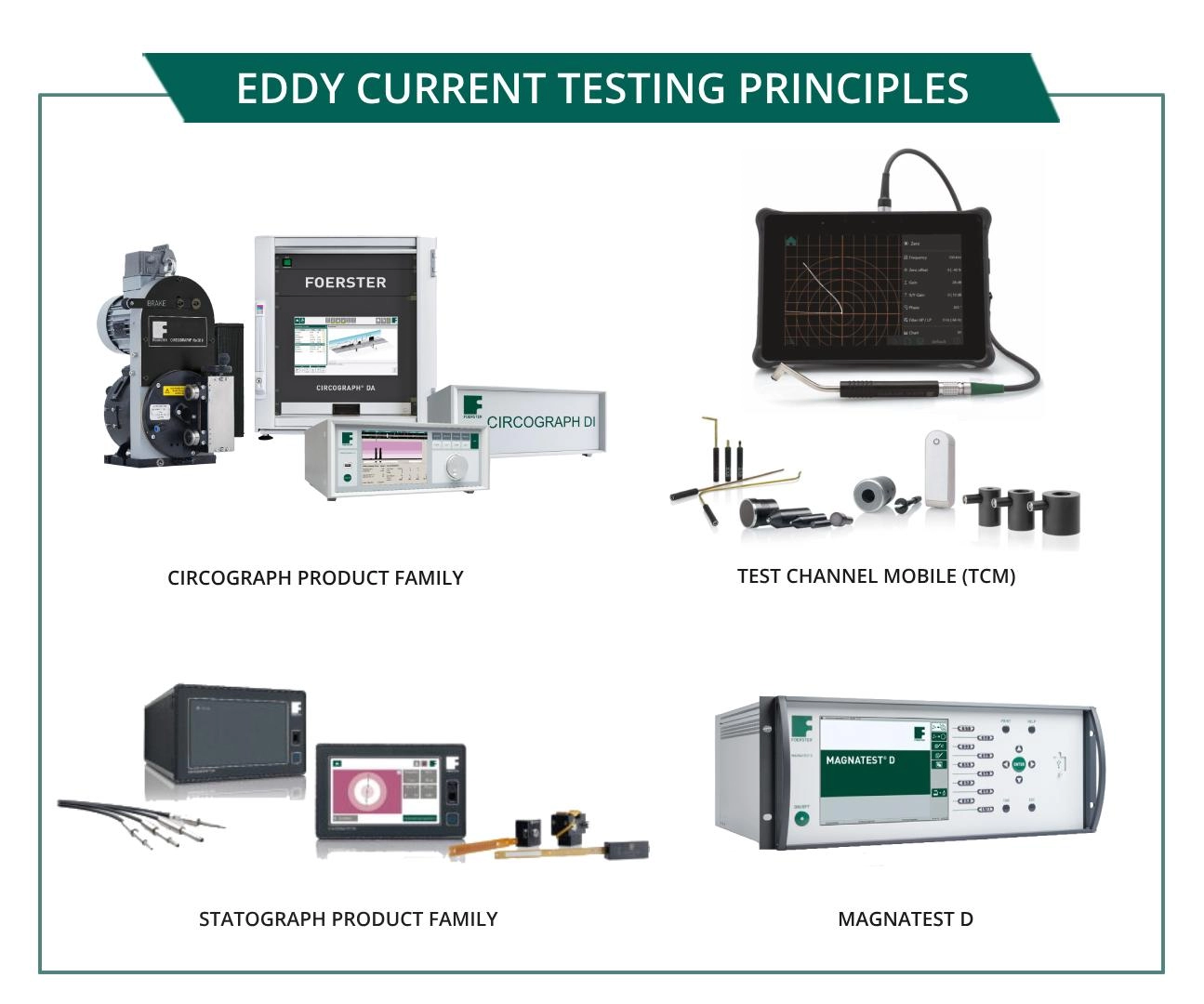

Nondestructive Testing

Also called Eddy current testing, this method detects flaws or cracks in metals without damaging the parts. It’s essential in aerospace, automotive, and manufacturing safety inspections.

-

Electromagnetic Brakes and Clutches

These devices use eddy current magnets to provide quick, precise torque control in machinery, improving response times and reducing mechanical wear.

-

Magnetic Levitation and Material Sorting

Eddy current magnets help levitate objects in maglev transport and sort non-ferrous metals in recycling, increasing efficiency and accuracy.

-

Emerging Technologies

New innovations include enhanced sensor technology, energy-efficient braking systems, and advanced material handling solutions, making eddy current magnets a growing force in modern magnetic applications.

From industrial heavy lifting to everyday safety equipment, these magnets keep things running smoothly without the downsides of mechanical wear or direct contact.

Advantages and Limitations of Eddy Current Magnets

Eddy current magnets offer several clear advantages, especially for U.S. industries looking for reliable and flexible magnetic solutions. One major plus is contactless operation—since they work without physical contact, there’s less wear and tear, leading to longer durability. These magnets also allow for precise controllability, making them ideal where adjustable magnetic force is needed, like in braking systems or material sorting.

In terms of durability, the lack of moving parts and friction means less maintenance compared to mechanical systems. Plus, their smooth, quiet operation fits well in environments that require minimal noise and vibrations.

However, there are some limitations. Eddy current magnets often generate heat during use because the induced currents create energy loss as heat. This can affect efficiency and may require cooling solutions, especially in heavy-duty applications. Another challenge is efficiency loss, as some energy gets wasted in creating these currents instead of performing mechanical work.

Comparing Eddy current magnets to traditional permanent magnets or electromagnets:

- Permanent magnets are simpler, require no power, and don’t generate heat but lack controllability.

- Electromagnets offer strong and adjustable magnetic fields but involve more complex power systems and can wear out coils.

- Eddy current magnets strike a balance with contactless, adjustable operation but need careful design to manage heat and efficiency.

For many U.S. industrial uses, the pros of Eddy current magnets—especially their durability and control—often outweigh the downsides, making them a solid choice where performance and low maintenance matter.

Selecting the Right Materials for Eddy Current Magnets

Choosing the right materials is critical for making Eddy current magnets that perform well and last long. The main components include good conductors and ferromagnetic materials. Conductors like copper and aluminum are key because they allow Eddy currents to flow easily, which is essential for generating the magnetic effects. At the same time, ferromagnetic materials such as iron or certain steel alloys help shape and enhance the magnetic field.

Material properties that influence Eddy current behavior include:

- Electrical conductivity: Higher conductivity means stronger Eddy currents.

- Magnetic permeability: Materials with high permeability guide magnetic fields efficiently.

- Thermal resistance: Since Eddy currents produce heat, materials must handle temperature changes without degrading.

- Mechanical strength: Durability ensures magnets withstand operational stresses.

NBAEM specializes in sourcing and delivering high-performance materials tailored for these needs. Their expertise in conductive and magnetic materials from China ensures reliable quality and consistent performance, meeting the demands of U.S. industrial customers. This focus on premium materials helps optimize Eddy current magnet efficiency and durability in real-world applications.

Maintenance and Safety Considerations

Proper care is key when working with Eddy current magnet-based devices to keep them running efficiently and safely. Here are some straightforward tips for maintenance and safety:

Maintenance Best Practices

- Regular inspection: Check for signs of wear, especially in conductive parts, to prevent unexpected failures.

- Cooling management: Because Eddy currents generate heat, ensure proper ventilation or cooling systems are in place to avoid overheating.

- Clean surfaces: Keep magnetic surfaces free from dust and debris to maintain optimal performance.

- Electrical connections: Inspect and tighten electrical contacts regularly to reduce resistance and energy loss.

- Material checks: Monitor the condition of ferromagnetic and conducting components, as material degradation can affect magnetic efficiency.

Safety Precautions

- Magnetic field exposure: Keep sensitive electronics and magnetic storage devices away from strong Eddy current magnets to prevent damage.

- Heat hazards: Be cautious of surfaces that may get hot during operation; use protective gloves or cooling pauses if needed.

- Proper handling: Use non-metallic tools when servicing magnets to avoid unintended eddy current generation.

- Secure mounting: Make sure devices are firmly installed to prevent movement caused by magnetic forces.

Following these guidelines helps maintain device longevity, minimizes efficiency losses, and keeps users safe from common risks associated with Eddy current magnet technology. For more on magnetic materials and safety, check out NBAEM’s insights on magnetic materials for sensor applications.

Future Trends in Eddy Current Magnetic Technology

Eddy current magnet technology is evolving fast, driven by innovations in materials and new applications. One major trend is the development of advanced magnetic materials that improve efficiency and reduce heat loss, which has long been a challenge in eddy current systems. NBAEM’s research and development focus on creating high-performance magnetic alloys and optimized conductor materials that enhance magnetic field control and durability.

We’re also seeing increased use of these magnets in cutting-edge fields like magnetic levitation, smart braking systems, and precision material sorting. As industrial processes demand more reliable and contactless solutions, eddy current magnets are becoming more versatile with better accuracy and lower maintenance needs.

Thanks to NBAEM’s commitment to innovation, customers in the US market can expect tailored magnetic solutions that push the limits of what eddy current technology can do. These improvements not only boost performance but also open doors for new applications in transportation, manufacturing, and nondestructive testing.

For more on how magnetic materials play a key role in these advances, check out NBAEM’s insights on magnets material and magnetic technologies.

[…] or stainless steel, acts as a barrier between magnets and fluid. However, it must minimize eddy currents—localized currents induced by the changing magnetic field that generate heat and decrease […]