What Is Geomagnetic Reversal? The Basics

Is the Earth about to physically turn upside down? Let’s clear up the biggest misconception right away. When we discuss a geomagnetic reversal, we are strictly talking about the planet’s magnetic North and South poles switching places—not the physical globe itself tipping over.

This phenomenon is driven by the Geodynamo process occurring deep beneath our feet. About 1,800 miles down, the Earth’s molten outer core acts like a massive, chaotic ocean of churning liquid iron. As this conductive fluid moves, it generates electrical currents that create our magnetic field. Because this flow is turbulent and chaotic, the field isn’t static; it wanders, weakens, and eventually flips.

The Timeline: A Slow Fade, Not a Snap

One of the most persistent myths is that an Earth’s magnetic field flip happens overnight. In reality, this is a gradual geological event.

- Duration: A full reversal typically takes between 1,000 to 10,000 years to complete.

- Process: The field doesn’t just snap to the opposite polarity; it weakens significantly, becomes complex (sometimes showing multiple poles), and then slowly re-establishes itself in the opposite direction.

Evidence from the Deep: How We Know

We aren’t guessing here. The history of these reversals is permanently recorded in the Earth’s crust through paleomagnetism evidence.

When lava erupts and cools, iron-rich minerals inside the rock align with the current magnetic north, locking that direction in place like a frozen compass. This is most visible in seafloor striping along mid-ocean ridges. As tectonic plates spread, they create a symmetrical pattern of magnetic “stripes”—alternating bands of normal and reversed polarity—that serve as a barcode of Earth’s magnetic history.

Key takeaways on the mechanics:

- Not a physical flip: Gravity and Earth’s axis remain unchanged.

- Driven by heat: Convection in the outer core powers the shift.

- Recorded in stone: Volcanic rocks provide the historical timeline.

Would you like me to detail the specific timeline of the last major reversal and the phenomenon of Superchrons next?

History and Frequency of Earth’s Magnetic Flips

When we look at the geological record, it becomes obvious that our planet doesn’t operate on a strict schedule. By analyzing paleomagnetism evidence locked inside ancient volcanic rocks, we can see that geomagnetic reversal is chaotic rather than periodic. Over the last 200 million years, the rhythm of these flips has varied wildly—occurring as frequently as every 20,000 years in some eras, while remaining static in others.

The Brunhes–Matuyama Reversal

The last full pole reversal took place roughly 780,000 years ago. This event, known as the Brunhes–Matuyama reversal, marks the start of our current magnetic epoch. Because it has been so long since the last flip, some assume we are “overdue,” but the Earth’s core doesn’t follow a set timetable. We also have evidence of “Superchrons”—periods like the Cretaceous Normal Superchron—where the poles refused to flip for nearly 40 million years, proving that stability can last much longer than average.

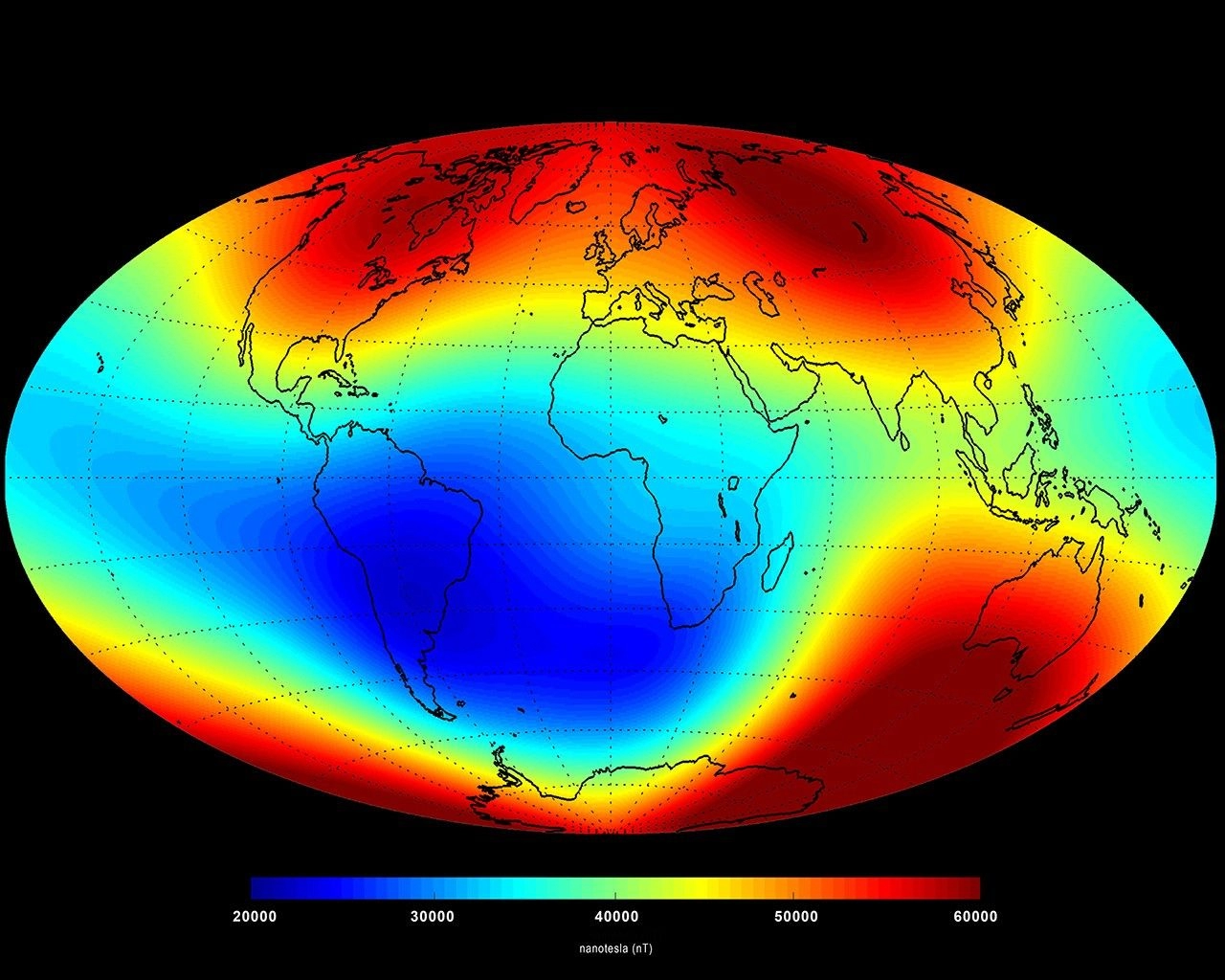

Current Status: The South Atlantic Anomaly

Right now, we are monitoring a measurable magnetic field weakening. Since 1840, the overall field strength has dropped by approximately 10%. The most significant activity is happening in the South Atlantic Anomaly (SAA), a massive weak patch in the field stretching from South America to Africa. Expansion data from the ESA Swarm satellite constellation confirms that the SAA is not only growing but also splitting into two distinct lobes, indicating complex changes in the dynamo processes deep beneath our feet.

Next Step: Would you like me to detail the specific engineering myths versus facts regarding the “Doomsday” scenarios associated with these reversals?

Are We Facing a Magnetic Reversal Soon? Myths vs. Facts

There is a lot of sensationalism surrounding the current state of our magnetosphere. We see the headlines about the field losing strength and the poles sprinting across the Arctic, but we need to separate Hollywood fiction from geophysical reality.

The current magnetic field weakening—observed as an intensity drop of roughly 10% since 1840—does not guarantee an immediate geomagnetic reversal. The Earth’s dynamo is turbulent. Historically, the field often weakens and then recovers its strength without ever completing a full flip. These aborted reversals, known as “excursions,” are far more common than a total pole reversal.

World Magnetic Model 2026 and Navigation Adjustments

Practically speaking, the shifting poles are a navigational challenge, not an apocalyptic one. The World Magnetic Model 2026 updates are critical because magnetic north is drifting rapidly from the Canadian Arctic toward Siberia.

This drift impacts everything from smartphone compasses to military navigation systems and airport runway designations. We have to constantly adjust our algorithms to keep up, but this is a standard correction procedure, not a sign of impending doom.

Radiation Risks and Debunking Doomsday Theories

Let’s be clear about the dangers. The idea that a magnetic reversal causes mass extinction is a myth. The fossil record and paleomagnetism evidence show that previous reversals did not correlate with cataclysmic die-offs. Our atmosphere provides a massive shield that remains intact even if the magnetic field weakens significantly.

However, the risk to technology is real.

- Surface Life: generally safe due to atmospheric shielding.

- Satellites and Astronauts: highly vulnerable to increased radiation risks and solar particles.

- Power Grids: susceptible to geomagnetically induced currents (GICs) during solar storms.

[Image of Earth magnetosphere deflecting solar wind]

We aren’t facing an biological extinction, but we are facing a potential technological disruption. The expanding South Atlantic Anomaly—a weak spot in the field allowing radiation to dip lower—already causes glitches in satellites passing over the region. Our focus shouldn’t be on doomsday bunkers, but on hardening our electrical infrastructure and satellite constellations.

The Engineering Pivot: Magnetic Reversal in Materials

While geologists worry about the Earth’s core, in the manufacturing world, we worry about the core of your motor. When we talk about magnetic reversal in engineering, we aren’t discussing a pole flip that takes a thousand years; we are defining a critical material failure known as demagnetization.

Understanding Magnetic Domains and Alignment

To understand why magnets fail, you have to look inside the material structure. A permanent magnet is made up of microscopic regions called magneettiset alueet.

- Unmagnetized state: These domains point in random directions, canceling each other out.

- Magnetized state: We apply a massive external field during manufacturing to force these domains to align in a single direction.

Magnetic domain reversal happens when an opposing external magnetic field or extreme heat forces these domains to snap back to a random state or, worse, flip to the opposite direction. Once that alignment is broken, you lose the flux driving your application.

The Role of Coercivity ($H_{cj}$) in Resisting External Fields

How do we stop this from happening? We focus on a property called Intrinsic Coercivity ($H_{cj}$). Think of $H_{cj}$ as the magnet’s immune system against demagnetization.

- Low Coercivity: easy to magnetize, but easy to demagnetize (like AlNiCo).

- High Coercivity: incredibly difficult to reverse (like NdFeB).

Korkea demagnetization resistance is non-negotiable for modern applications. If the external field strength exceeds the magnet’s intrinsic coercivity, the magnet is effectively “overpowered,” causing immediate performance loss.

Why Accidental Reversal is a Nightmare for EV Motors and Robotics

In dynamic applications, accidental reversal is catastrophic. Consider lämpötilaan liittyvä demagnetisaatio in an electric vehicle (EV) or a high-speed servo. These motors generate immense heat and strong opposing magnetic fields during operation.

If the permanent magnets inside the rotor undergo reversal:

- Torque Ripple: The motor starts to “stutter.”

- Efficiency Drop: Power consumption spikes while output creates heat instead of motion.

- System Failure: The motor can seize or completely lose its ability to drive the load.

This is why permanent magnet stability is the top priority when sourcing magnets used in industrial automation and robotics. We simply cannot afford materials that lose their “direction” under pressure.

Next Step: Would you like me to detail the specific high-coercivity grades of NdFeB and SmCo magnets that are best suited to prevent these reversals in high-temperature environments?

How High-Coercivity Magnets Resist Reversal

When we engineer magnetic systems, specifically for traction motors or high-speed rotors, “reversal” is the enemy. To prevent a magnet from losing its charge when faced with a strong opposing field or high heat, we rely on intrinsic coercivity (Hcj). Think of coercivity as the magnet’s “stubbornness”—its ability to refuse to flip its internal magnetic domains.

Comparing Materials: NdFeB, SmCo, and AlNiCo

Not all permanent magnets handle this stress the same way. Selecting the right material is the first line of defense against demagnetization resistance.

- NdFeB-magneetit: These offer the highest energy density. However, standard grades can be vulnerable to thermal demagnetization. We have to use specific high-Hcj grades (like UH or EH series) to ensure they survive in EV motors.

- SmCo-magneetit: If stability is the priority over raw strength, we often look to korkean suorituskyvyn SmCo-magneetit. They possess naturally high coercivity and exceptional thermal stability, making them almost immune to accidental reversal in standard operating conditions.

- AlNiCo Magnets: While they handle heat incredibly well, AlNiCo-magneeteista have very low coercivity. They are easily demagnetized by external fields, which is why we rarely use them in dynamic motor applications where opposing fields are constant.

Grain Boundary Engineering and Diffusion

To make NdFeB-magneetteihin tough enough for automotive applications without switching to expensive Samarium Cobalt, we use advanced processing techniques.

- Grain Boundary Engineering: We modify the microstructure of the magnet, isolating individual magnetic grains. This prevents a “domino effect” where one reversed grain flips its neighbors.

- Heavy Rare-Earth Diffusion: Instead of adding expensive Dysprosium (Dy) or Terbium (Tb) to the whole magnet, we diffuse it mainly into the grain boundaries. This boosts intrinsic coercivity (Hcj) significantly without sacrificing the magnet’s overall power (Remanence).

Optimizing the BH Curve

ly, avoiding reversal comes down to reading the BH curve. Every magnet has a “knee point” on its demagnetization curve. If the operating point of the motor pushes the magnet past this knee—due to a current spike or temperature rise—the magnetic domain reversal becomes permanent. We design our magnetic circuits to ensure the load line always stays safely above this knee point to prevent catastrophic failure.

Next Step:

Would you like me to detail the specific ISO testing protocols we use to verify the coercivity of these materials before shipment?

Real-World Applications and NBAEM Solutions

When we talk about magnetic reversal in an engineering context, we are really talking about reliability. If the magnets in a high-performance machine lose their orientation or demagnetize, the system fails. At NBAEM, we focus on engineering materials that resist these reversals under extreme conditions, ensuring stability for the technologies that drive the modern world.

Stabilizing Permanent Magnet Synchronous Motors (PMSM) in EVs

Electric vehicles rely heavily on Permanent Magnet Synchronous Motors (PMSM). These motors generate intense heat and opposing magnetic fields during operation, creating a perfect storm for accidental demagnetization. We tackle this by utilizing high coercivity magnets—specifically engineered NdFeB grades with heavy rare-earth diffusion. This ensures the magneettiset alueet remain locked in alignment, preventing torque loss or sudden failure even when the motor is pushed to its thermal limits.

Wind Turbines: Handling High Stress Without Flux Loss

Wind turbines operate in harsh environments where maintenance is difficult and costly. The magnets inside the generator must maintain their field strength for decades. Our solutions for permanent magnet generators are designed to withstand high operational stress without suffering from flux loss. By optimizing the intrinsic coercivity (Hcj), we ensure these giants keep generating power efficiently, regardless of the load.

Custom Assemblies: Halbach Arrays and Lamination Cores

Standard magnets don’t always cut it for specialized applications. We provide custom assembly solutions to maximize efficiency:

- Halbach Arrays: We arrange magnets to augment the magnetic field on one side while canceling it on the other, ideal for high-precision robotics and particle accelerators.

- Lamination Cores: To reduce eddy current losses in high-speed motors, we integrate laminated magnet assemblies that keep the system cool and efficient.

Ensuring Orientation with ISO-Certified Testing

Manufacturing the magnet is only half the battle; proving it works is the other. We back our materials with comprehensive technical services, including rigorous HAST (Highly Accelerated Stress Test) ja PCT (Pressure Cooker Test) protocols. These ISO-certified tests verify that our materials resist corrosion and thermal demagnetization, guaranteeing that when you install an NBAEM component, it stays oriented exactly how it was designed.

Would you like me to analyze the specific coercivity requirements for your next high-temperature motor project?

Jätä kommentti