Guide to Rare Earth Magnets

Rare earth magnets are everywhere—from your smartphone to your car. But most people don’t know what makes them different or why they cost more.

Rare earth magnets are the strongest permanent magnets, made from rare-earth element alloys like neodymium and samarium cobalt, and are used in many high-performance applications.

In my work, I deal with rare earth magnets every day. I’ve seen how small they are, but also how powerful. Whether for tech or tools, their magnetic force is unmatched. Let me walk you through everything you need to know.

What are earth magnets?

People often hear “earth magnet” and think it’s something new. Actually, it’s been transforming industries for decades.

Earth magnets, or rare earth magnets, are made from rare-earth elements like neodymium and samarium, and are known for their high magnetic strength.

rare earth

What makes them rare?

Rare earth elements come from the lanthanide series of the periodic table. These metals aren’t truly rare in quantity, but they are hard to extract and process. This is what gives the magnets their name.

Two main types

There are two popular kinds of rare earth magnets:

- Neodymium magnets (NdFeB): Made from neodymium, iron, and boron. Very strong, often nickel-coated to resist rust.

- Samarium cobalt magnets (SmCo): Made from samarium and cobalt. Better at handling high temperatures and resisting corrosion.

Here’s a quick comparison:

| Type | Composition | Strength | Corrosion Resistance | Temperature Stability | Cost |

|---|---|---|---|---|---|

| Neodymium (NdFeB) | Nd + Fe + B | Very high | Low (needs coating) | Medium (~80–200°C) | Lower |

| Samarium Cobalt (SmCo) | Sm + Co | High | Excellent | High (~250–350°C) | Higher |

They look small, but their strength is no joke. I’ve had a 1-inch neodymium magnet jump across a table and snap onto a metal wrench. It startled me the first time. That’s when I realized how powerful they are.

What is the difference between an earth magnet and a regular magnet?

If you’ve ever used a fridge magnet and thought, “This works fine,” you haven’t met a rare earth magnet.

Earth magnets are much stronger than regular magnets like ceramic or alnico, and can hold heavier loads in smaller sizes.

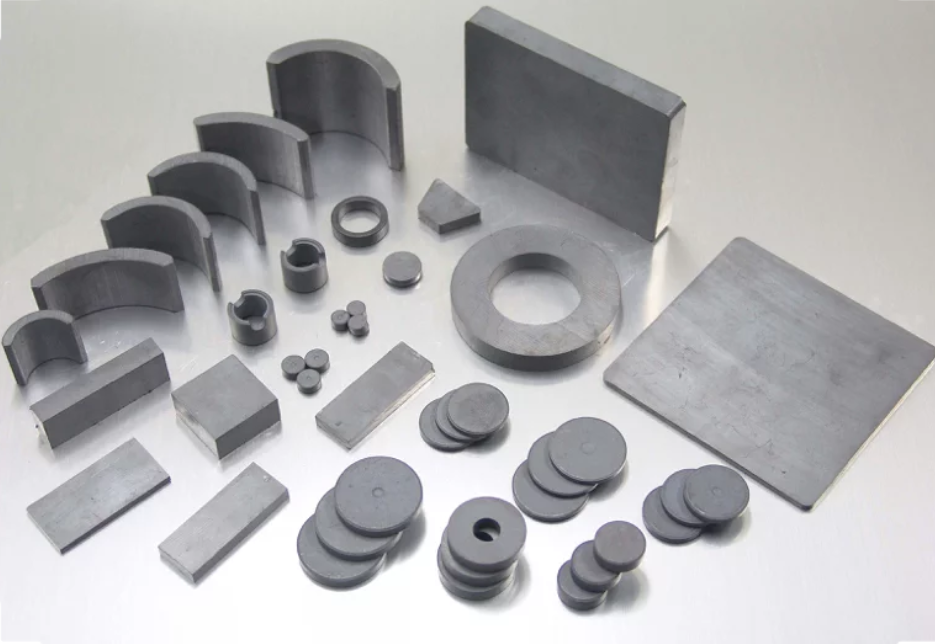

Ferrite magnet

Performance gap

The strength difference between rare earth and regular magnets is dramatic. A small neodymium magnet can be 10 times stronger than a similarly sized ceramic magnet. That’s why tech companies use them in smartphones, hard drives, and electric motors.

Key differences by type

Let’s break this down:

| Property | Ceramic Magnet (Ferrite) | Alnico Magnet | Rare Earth Magnet |

|---|---|---|---|

| Magnetic Strength | Low to Medium | Medium | Very High |

| Size Efficiency | Large | Medium | Small |

| Cost | Low | Medium | High |

| Corrosion Resistance | Good | Poor | Varies (coated NdFeB) |

| Temp. Stability | High | Very High | Medium to High |

Before I learned the differences, I tried to use a ceramic magnet for a small motor project. It didn’t work well. After switching to neodymium, the motor performed much better—even though the magnet was half the size.

What are neodymium magnets used for?

Most people have no idea how many things rely on these tiny powerhouses.

Neodymium magnets are used in electric motors, headphones, hard drives, medical devices, wind turbines, and various consumer electronics.

use of magnet

High-demand applications

Here are the main areas I’ve seen them used:

- Electric vehicles (EVs): Neodymium magnets power the traction motors.

- Wind turbines: Used in direct-drive generators.

- Electronics: Found in speakers, microphones, and hard drives.

- Medical: Used in MRI machines and surgical tools.

- DIY & industrial tools: Strong holding tools, magnetic clamps, sensors.

Here’s a breakdown:

| Industry | Use Case | Reason for Use |

|---|---|---|

| Automotive | EV motors, ABS sensors | Small size + high strength |

| Electronics | Headphones, hard drives | Light weight, strong performance |

| Medical | MRI, surgical instruments | Stable and reliable |

| Renewable Energy | Wind turbines | Durable and efficient |

| Industrial | Magnetic separators, lifts | High holding force |

The first time I saw one in action was during a speaker repair job. The sound was weak with a ceramic magnet. Swapped in a neodymium version—instantly clearer sound and better bass.

Why are rare earth magnets so expensive?

Customers often ask me why these magnets cost so much. The answer has many layers.

Rare earth magnets are expensive because of complex mining processes, limited global supply, and high processing and refinement costs.

Raw material scarcity

Mining rare earth metals like neodymium or samarium requires special handling. These materials are not truly rare, but they are scattered and hard to refine. Most global supply comes from a few countries, which adds to market risk and pricing.

Manufacturing complexity

The magnets must be processed at high purity, sintered at controlled temperatures, and often coated (especially NdFeB) to resist corrosion. Each step adds cost. On top of that, environmental regulations and export controls (like China’s 2025 policies) impact supply and price.

Here’s what affects the price:

| Factor | Description |

|---|---|

| Raw Material Cost | Rare earths are expensive to extract and refine |

| Processing Difficulty | Requires high-tech sintering and coating |

| Supply Chain Risk | Limited suppliers, trade policies, and export limits |

| Performance Demand | Used in cutting-edge tech and green energy systems |

Sometimes I explain it like this: buying a rare earth magnet is like buying a tiny engine. It may not look complex, but it’s packed with power and precision.

Conclusion

Rare earth magnets are small but mighty. Their strength, efficiency, and broad use make them essential for modern industries.

My Role

About me

Brand Name: NBAEM Magnet

Slogan: Specialized in magnetic materials

Website: nbaem.com

Our Mission:

NBAEM Magnet is a magnet company with 15 years of experience. We specialize in various types of magnetic materials, aiming to help each customer create cost-effective customized magnets and magnetic components that meet their specific requirements. We provide high-quality pre-sales and after-sales services, along with relevant technical support.

About me:

NBAEM was founded by me—a passionate professional in the magnet industry. I started my career at a magnet factory and later established a successful magnet and magnetic assembly company. Through my journey in the magnet industry, I have helped many clients grow their businesses. By sharing my expertise and experience, I aim to help clients find the right solutions.

[…] more insights on high-performance magnetic materials and rare earth magnet types, check out our Guide to Rare Earth Magnets and learn about their uses in electric motors like Magnets in Coreless […]

[…] into the stream. To understand the power source behind this capture efficiency, you can look at our guide to rare earth magnets, which explains the core materials we use to achieve surface field strengths up to 12,000 Gauss. […]

[…] the strongest part of the magnetic field rather than sliding between them. Understanding the guide to rare earth magnets is essential for selecting the right material grade to pair with these custom physical […]