Magnets are used in many industries from manufacturing to engineering and are often required to perform in extreme temperature conditions. Selecting the right magnet for high-temperature applications is critical to getting the best performance and durability. In this article, we’ll look at how temperature affects magnets and go over the main types of high-temperature resistant magnets, their properties, and typical applications.

How Temperature Affects Magnet Performance

Before we dive into the types of high-temperature resistant magnets, let’s talk about how the ambient temperature affects the magnetic properties. In general, heat reduces the strength of a magnet, and cold increases its magnetism. High-temperature environments can cause magnets to lose some of their magnetization permanently, depending on how far above the magnet’s limits the operating temperature is.

1) Maximum Operating Temperature vs. Curie Temperature:

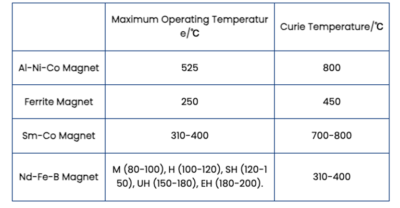

Every magnet has a maximum operating temperature where it starts losing its magnetic properties. Once you exceed this temperature, you’ll have irreversible magnetic loss. The Curie temperature is the point where a magnet loses all magnetization. Both of these temperatures are different for different types and grades of magnets.

2) Reversible vs. Irreversible Magnetic Loss:

If you heat a magnet above its maximum operating temperature but not to its Curie temperature, it may experience reversible loss. This means the magnet’s strength can come back once it cools down. However, if you expose it to extreme temperatures for a long time or get it up to Curie temperature, you’ll have irreversible loss. This means the magnetism will not come back.

Common Types of High-Temperature Resistant Magnets

Here are the most common high-temperature resistant magnets you can use. Each one has unique properties that make it good for different applications.

Maximum Operating Temperature: Up to 525°C

Curie Temperature: ~850°C

AlNiCo magnets are made from an alloy of aluminum, nickel, cobalt, and iron. They can handle the highest temperatures of any commercial magnets, going up to 525°C. People use them in sensors, guitar pickups, and high-temperature industrial applications because they are so thermally stable. Although they’ve been replaced by more powerful rare-earth magnets in many applications, people still like to use AlNiCo magnets in places with extreme heat.

Maximum Operating Temperature: Up to 250°C

Curie Temperature: ~450°C

Ferrite magnets, also called ceramic magnets, are made mostly from iron oxide and other metallic elements. Although they have a lower temperature limit than other high-temperature magnets, they’re inexpensive and electrically insulating. You’ll find them used in transformers and computer cables because they’re an economical solution for applications that don’t exceed 250°C.

Maximum Operating Temperature: 310-400°C

Curie Temperature: ~700°C

Samarium Cobalt (SmCo) magnets are very durable, having high magnetic strength and excellent temperature resistance. These magnets are great for high-temperature environments, especially in aerospace and automotive engineering. They’re more resistant to corrosion and oxidation than neodymium magnets and have excellent demagnetization resistance. That’s why you see them used in applications with both high and low-temperature extremes.

Maximum Operating Temperature: 80-200°C depending on the grade

Curie Temperature: 310-340°C

Neodymium magnets are the strongest commercially available magnets you can get in terms of magnetic power. However, their high-temperature resistance is lower than SmCo and AlNiCo magnets. Neodymium magnets have different grades based on how much heat they can handle:

M (80-100°C)

H (100-120°C)

SH (120-150°C)

UH (150-180°C)

EH (180-200°C)

In a high-temperature environment, neodymium magnets lose 0.11% of their magnetism for each 1°C increase in temperature. This loss is usually reversible as long as you don’t exceed the maximum temperature.

Max working temperature for AlNiCo magnet, ferrite magnet,SmCo magnet, NdFeB magnet

Key Factors Influencing Magnet Performance in High Temperatures

In addition to the type of magnet, there are a few other things to consider when it comes to how magnets perform at high temperatures:

Ambient Temperature and Humidity:

Magnets exposed to high temperatures and humid conditions can go bad more quickly. Neodymium magnets, for example, will corrode, so they’re usually coated with something like nickel or epoxy to protect them in those environments.

Material Composition:

Different magnets are made of different stuff and, therefore, have different resistance levels. Ferrite magnets, for example, are ceramic-based, so they’re very resistant to heat but brittle. Neodymium magnets, on the other hand, are made of a metal alloy, so they need to be coated to last, especially in humid or corrosive environments.

High-Temperature Magnet Applications

There are many industries where you need magnets that can handle high temperatures because the performance needs to stay consistent when things get hot:

Aerospace: Turbine engines and other parts use high-temperature magnets where the temperature is high.

Automotive: Electric motors, sensors, and other car parts use magnets that can handle high temperatures because the engine and other parts get hot.

Manufacturing and Engineering: High-temperature magnets are used in industrial processes like welding or high-heat machining. They keep their magnetism even though the temperature fluctuates.

Medical Devices: Some medical equipment and instruments need magnets that work at sterilization temperatures, which are high.

How to Choose High-Temperature Magnets

The right high-temperature magnet for your application depends on your specific operating conditions. You need to know the maximum temperature, how long the magnet will be exposed to that temperature, and environmental factors like humidity. AlNiCo, ferrite, SmCo, and NdFeB magnets all have different heat resistance levels. Each is used in different commercial and industrial applications. Before you choose a magnet, you need to know the maximum operating temperature and the Curie temperature of the magnet.

For more information about high-temperature magnets or to get a quote for your magnet needs, visit NBAEM. We work with companies and industries around the world to provide high-quality solutions.

[…] more on selecting magnets that handle high temperatures, check out NBAEM’s lineup of high temperature magnets. They offer reliable solutions tailored for tough thermal environments, ensuring you get the best […]

[…] For projects that face heat or corrosive environments, check specific high temperature magnets information here: https://nbaem.com/high-temperature-magnets/ […]

[…] temperature motor magnets reach their limit. For heavy-duty industrial cycles, I often pivot to high-temperature magnets that maintain stability under thermal […]

[…] 80°C. If your process involves heat, such as in plastics or chemical processing, you must specify high-temperature magnets capable of withstanding up to 350°C to maintain magnetic flux […]