If you’ve ever wondered how SmCo magnets are made and what sets them apart in the world of rare-earth magnets, you’re in the right place. These powerful Samarium Cobalt magnets are critical in high-performance applications where durability and magnetic strength matter most. In this guide, we’ll break down the entire SmCo magnet manufacturing process — from raw materials to finished product — revealing the expert techniques that suppliers like NBAEM use to deliver consistent quality and precision. Whether you’re an engineer, buyer, or industry professional, understanding these steps will give you the confidence to choose the right SmCo magnets for your needs. Let’s get started!

SmCO magnets

Understanding SmCo Magnets

Samarium Cobalt (SmCo) magnets are a type of rare earth magnet known for their exceptional strength and stability. Made from an alloy of samarium and cobalt, these magnets provide high magnetic performance along with excellent resistance to corrosion and temperature. SmCo magnets typically operate in temperatures up to 250°C, making them ideal for demanding environments.

Key physical and magnetic properties include:

- High magnetic energy product (stronger magnetic force per volume)

- Excellent thermal stability and resistance to demagnetization

- Superior corrosion resistance compared to other rare earth magnets

- Brittle and hard, requiring careful machining and handling

Industries that use SmCo magnets span aerospace, automotive, medical devices, and electronics. They are common in high-performance motors, sensors, actuators, and precision instruments where reliability and strength are critical. For an overview of magnets in industrial use, you can visit magnets used in industrial.

Raw Materials Used in SmCo Magnet Production

The main ingredients in making SmCo magnets are samarium (Sm) and cobalt (Co). These two rare earth elements form the core of the magnet’s strong magnetic properties. Samarium provides excellent temperature stability, while cobalt adds to the magnet’s overall strength and durability.

Besides samarium and cobalt, manufacturers often add small amounts of other elements like iron, copper, or zirconium. These additives help improve magnetic performance, increase corrosion resistance, and control grain structure during production.

Material purity is critical in SmCo magnet production. Even minor impurities can weaken the magnet’s performance and consistency. NBAEM follows strict supply chain standards to source high-grade raw materials. They carefully select suppliers and conduct thorough quality checks to ensure the samarium and cobalt meet tight chemical composition and purity requirements. This focus on raw materials quality contributes to the reliability and performance of their SmCo magnets, especially suited for demanding industrial applications in the worldwide market.

Step-by-Step Manufacturing Process of SmCo Magnets

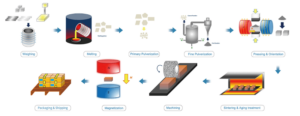

Samarium cobalt magnet production flow

Making SmCo magnets involves several precise steps to ensure strong magnetic performance and durability. Here’s a simple breakdown:

Alloy Preparation

- Raw samarium (Sm) and cobalt (Co) metals are melted together in vacuum induction furnaces.

- Strict control of chemical composition ensures uniform alloy quality.

- Homogeneity in the melt prevents weak spots in the magnets.

Ingot Casting

- The molten alloy is cast into ingots using continuous or mold casting methods.

- Controlled cooling solidifies the metal while maintaining the right microstructure.

Crushing and Milling

- Ingots are crushed into smaller chunks.

- Jet milling pulverizes these chunks into fine powders with controlled particle size for better compacting.

Powder Handling and Blending

- Powders are handled in an inert or protective atmosphere to prevent oxidation.

- Lubricants or binders are added to improve powder pressability.

Pressing and Compacting

- Powders are pressed using magnetic field or isostatic methods, aligning magnetic domains to maximize performance.

- Pressing direction is critical—it influences the magnet’s final strength.

Sintering

- Compacted parts are sintered at high temperature under vacuum or inert gas.

- Grain growth is carefully controlled to optimize magnetic properties.

Heat Treatment Aging

- Post-sintering heat treatment relieves internal stresses and boosts coercivity (resistance to demagnetization).

- Parameters like temperature and duration are fine-tuned for best results.

Machining and Grinding

- Magnets are cut and ground to precise dimensions with specialized equipment.

- Techniques used avoid damaging magnetic properties during shaping.

Coating and Surface Treatment

- Anti-corrosion coatings like nickel or epoxy are applied to extend magnet lifespan.

- Proper surface treatment improves durability in harsh environments.

Each step in this process is essential to producing high-quality SmCo magnets that perform reliably in various industrial applications. For more on magnet types and how these fit into industry needs, check out this for different magnetic material.

Quality Control and Testing

Quality control is crucial in SmCo magnet manufacturing to ensure each magnet performs reliably. At NBAEM, the process covers several key areas:

Chemical Composition Analysis

- Raw materials and finished magnets undergo strict chemical checks.

- Precise ratios of samarium, cobalt, and additives are verified to meet specs.

Magnetic Property Testing

- Coercivity, remanence, and energy product values are measured to confirm magnetic strength and stability.

- Each batch is tested to ensure consistent magnetic performance required for industrial use.

Mechanical Property Tests

- Hardness, density, and structural integrity are checked to guarantee durability.

- Tests help prevent defects that could affect magnet lifespan or functionality.

Standards Compliance

- NBAEM adheres to ISO and other global quality standards.

- This ensures magnets meet international industrial requirements, particularly for the U.S. market.

NBAEM Quality Assurance Practices

- Continuous monitoring during production to detect issues early.

- Use of advanced equipment and experienced technicians for reliable results.

- Documentation and traceability maintain high transparency for customers.

This comprehensive quality control assures that SmCo magnets from NBAEM deliver dependable performance across all applications.

Advantages of NBAEM SmCo Magnets Manufacturing Process

NBAEM stands out in the SmCo magnet market because of its strong focus on technology and quality. Their advanced equipment ensures precise control over every production step, from alloy preparation to final coating. This tech edge helps deliver magnets with consistently high performance that meet strict industry standards.

The experienced R&D team at NBAEM constantly works to improve the manufacturing methods. This means clients benefit from magnets tailored to specific needs, whether for aerospace, electronics, or medical devices. NBAEM’s process allows easy customization and scalability, making it flexible for both small and large orders.

Environmental responsibility is another benefit of working with NBAEM. They apply sustainable practices like minimizing waste and reducing energy use during sintering and heat treatment. This helps lower the carbon footprint while maintaining the high quality customers expect.

In , NBAEM combines advanced technology, expert development, customization options, and eco-friendly processes to deliver reliable SmCo magnets suited to worldwide industrial demands.

Common Challenges in SmCo Magnet Manufacturing and How NBAEM Overcomes Them

SmCo magnet manufacturing faces several tough challenges, especially when serving demanding industries in the market. NBAEM tackles these head-on to deliver reliable, high-performance magnets.

Managing Material Costs and Supply Chain Risks

Samarium and cobalt prices can fluctuate, affecting production costs. NBAEM maintains strong relationships with trusted suppliers and follows strict NBAEM supply chain standards to secure high-purity raw materials consistently. This approach helps control costs and avoid sudden shortages.

Avoiding Oxidation and Impurities

SmCo materials are sensitive to oxygen, which can hurt magnetic properties. NBAEM uses protective atmospheres throughout powder handling and processing. Their airtight milling, blending, and sintering setups minimize oxidation and contamination, ensuring clean, high-quality magnets.

Precision Manufacturing Challenges

SmCo magnets require precise control during pressing, sintering, and machining to achieve targeted magnetic performance and exact dimensions. NBAEM leverages advanced equipment and experienced technicians to maintain tight tolerances while orienting magnetic domains correctly, preserving magnetic strength.

Delivering Consistent High-Performance Magnets

Consistency is crucial for industrial applications. NBAEM’s continuous quality control protocols — including chemical composition checks and magnetic property testing — guarantee every batch meets strict standards for coercivity, remanence, and energy product. This reliability gives customers the confidence they need for their end products.

By tackling these common hurdles with robust processes and quality assurance, NBAEM stands out as a trusted Chinese SmCo magnet supplier focused on meeting industrial needs. For more insights on SmCo magnet performance and heat treatment, check out NBAEM’s detailed high-performance SmCo magnets guide.

[…] SmCo magnets made with advanced processes (see how SmCo magnets are made) […]