What is a Halbach Array Magnets

A Halbach array Magnets is a special arrangement of permanent magnets that boosts the magnetic field on one side while nearly canceling it on the other. This design was invented by physicist Klaus Halbach in the 1980s, originally for particle accelerators.

Key features of Halbach array Magnets

- Magnetic poles rotated sequentially so the magnetic field lines concentrate on one side.

- Asymmetric field distribution, creating a strong magnetic flux on the “active” side.

- Reduced magnetic field leakage on the opposite side, making the array more efficient.

How it differs from conventional magnet arrays

| Feature | Conventional Magnet Array | Halbach Array Magnets |

|---|---|---|

| Magnetic field distribution | Symmetric, equal on both sides | Enhanced on one side, canceled on the other |

| Magnetic efficiency | Standard | Higher, due to field concentration |

| Magnetic interference | Often significant | Minimized on the quiet side |

| Typical applications | Basic magnetic tasks | Advanced motors, levitation, MRI |

This unique orientation of magnetic poles sets Halbach arrays apart, offering better performance in various industrial and technological uses.

Working Principle of Halbach Array magnets

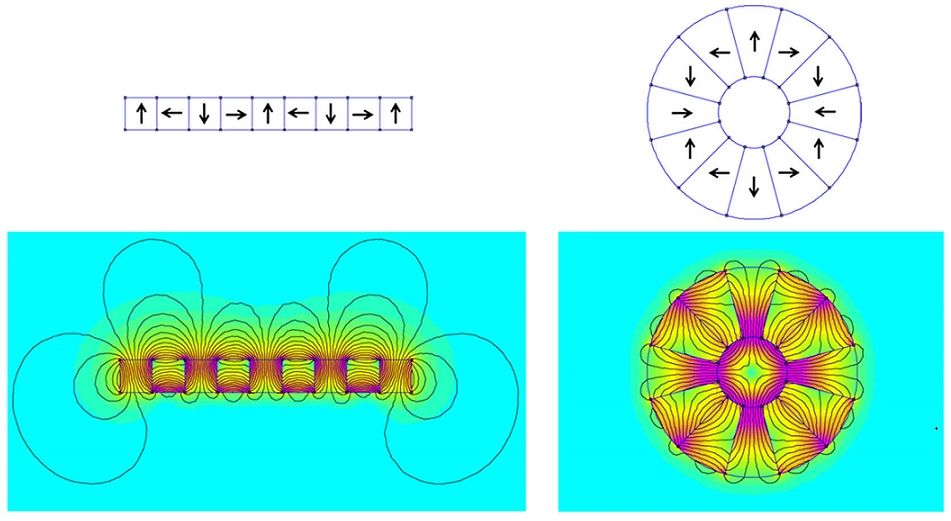

A Halbach array Magnets works by arranging magnets so their magnetic fields combine to create a strong magnetic field on one side while nearly canceling it on the opposite side. This is achieved by carefully orienting each magnet’s poles in a specific pattern, causing the magnetic vectors to add up on the “active” side and interfere destructively on the “quiet” side.

Imagine a line of magnets where each magnet’s north and south poles rotate progressively. This rotation causes the magnetic field lines to concentrate and point outward on one side, boosting the magnetic flux density there. On the opposite side, the fields effectively cancel each other out, reducing stray magnetic flux.

Visualizations of Halbach arrays often show tight, dense magnetic flux lines clustered on the strong side, illustrating how field strength improves without increasing magnet size or weight. This concentration of magnetic flux means the array delivers more power and efficiency where it’s needed, making it ideal for applications like magnetic levitation and electric motors.

Types of Halbach Arrays Magnets

Halbach arrays magnets come in different shapes depending on their use. The most common types are:

-

Linear Halbach Array Magnets

Magnets are arranged in a straight line with their poles oriented to create a strong magnetic field on one side. These are often used in magnetic levitation tracks and linear motors.

-

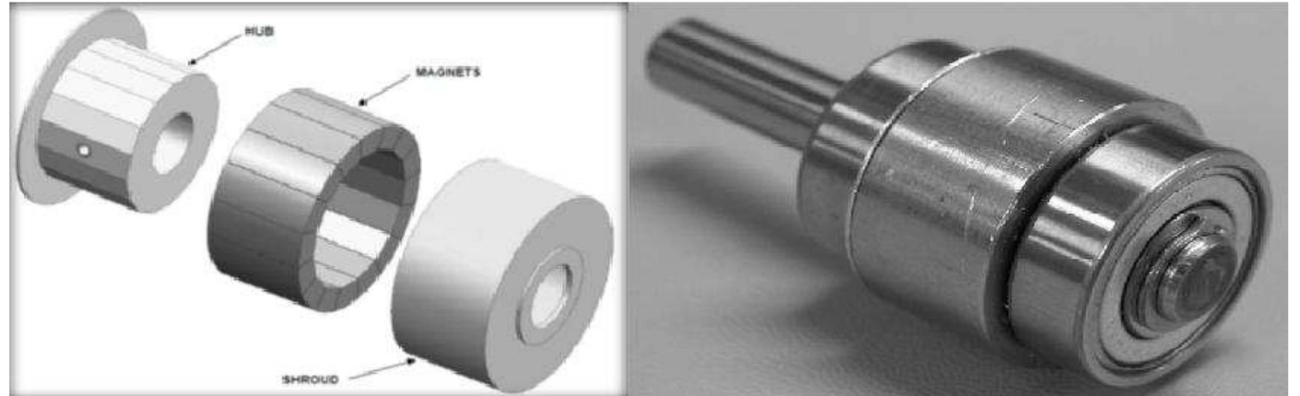

Circular Rotor Halbach Array Magnets

Magnets are positioned around a circle, typically inside motors or generators, producing a concentrated magnetic field on the rotor’s inside or outside. This design boosts torque and efficiency.

-

2D and 3D Halbach Array Configurations

These are more complex layouts where magnets are arranged in two or three dimensions to shape the magnetic field precisely. They’re useful in applications like MRI machines or advanced magnetic bearings.

Each type targets specific needs: linear arrays work well for straight-line motion control, circular rotors optimize rotating devices, and 2D/3D arrays allow fine-tuned magnetic fields in sophisticated systems. Understanding these differences helps when choosing or building a Halbach array magnets for your project.

Advantages of Halbach Array Magnets Compared to Traditional Magnets

Halbach arrays offer several clear benefits over traditional magnets, especially when you need a strong, focused magnetic field.

- Stronger magnetic field on one side: The unique arrangement of magnetic poles concentrates the magnetic flux on the targeted side, creating a much stronger field than regular magnets. This eliminates back field leakage, meaning the other side has little to no stray magnetic field.

- Improved efficiency in motors and magnetic coupling: By focusing the magnetic force where it’s needed, Halbach arrays boost motor torque and improve energy transfer in magnetic couplings, resulting in better overall performance and reduced power losses.

- Reduced magnetic interference: The “quiet” side of the array has significantly less stray magnetic flux, which lowers the risk of interference with nearby electronic components or sensitive equipment. This is a big advantage in compact or complex designs.

- Compact and lightweight design: Because the magnetic field is stronger and more directed, less material is needed to achieve the same effect as larger traditional magnets. This makes devices using Halbach arrays smaller, lighter, and more efficient.

These advantages make Halbach arrays especially popular in high-performance applications like electric motors, magnetic levitation, and precision instruments. For more on magnet types and materials, check out the types of magnets and NdFeB magnets Halbach array resources.

Practical Applications of Halbach Array Magnets

Halbach arrays are making a big impact in many industries thanks to their unique magnetic field properties. Here are some key practical uses in the market:

-

Magnetic Levitation Maglev Trains

Halbach arrays create strong magnetic fields on one side, allowing trains to levitate and glide with minimal friction. This boosts efficiency and cuts down on maintenance for high-speed rail systems.

-

Electric Motors and Generators

Thanks to enhanced magnetic flux concentration, Halbach arrays improve torque density. This means motors and generators become more powerful and compact—perfect for electric vehicles and renewable energy setups where space and efficiency matter.

-

Magnetic Resonance Imaging (MRI) Systems

Halbach arrays magnets help focus magnetic fields precisely, improving image quality while reducing interference. This leads to more reliable scans and better diagnostics.

-

Particle Accelerators

Their ability to direct magnetic fields efficiently makes Halbach arrays essential in steering and focusing particle beams in research facilities and medical equipment.

-

Magnetic Bearings and Clamps

The arrays offer strong holding forces on one side without magnetic leakage, ideal for magnetic bearings that reduce friction and for clamps used in assembly or manufacturing.

-

Novel Tech Applications

New uses are popping up in wind turbines for better power output and in speaker design for enhanced sound quality through precise magnetic control.

These diverse applications highlight why Halbach arrays are becoming a go-to solution for industries demanding stronger, more efficient magnetic performance.

Manufacturing and Material Considerations

When it comes to making Halbach arrays, the choice of magnetic materials is crucial. The most common magnets used are Neodymium Iron Boron (NdFeB) and Samarium Cobalt (SmCo). NdFeB offers very strong magnetic fields and is widely popular for high-performance applications, while SmCo provides better heat resistance and corrosion durability, which is important in harsh environments.

Producing Halbach arrays involves precise magnetization techniques. Each magnet segment must be magnetized in a specific direction to create the unique Halbach field pattern—this requires careful control and specialized equipment. Challenges include maintaining consistent magnetic orientation and strong adhesion between segments to ensure the array works efficiently without losing strength over time.

NBAEM plays an important role by supplying high-quality magnets tailored for Halbach arrays. Their expertise covers custom magnet shapes, precise magnetization, and reliable materials to meet industrial needs. Whether you need NdFeB or SmCo magnets, NBAEM’s solutions support both standard and complex Halbach designs, ensuring top performance and durability.

For more details on magnetic materials and types, check out NBAEM’s magnet materials overview.

Case Study NBAEMs Halbach Array Magnets Solutions

NBAEM is a trusted name in supplying high-quality magnetic materials, especially NdFeB and SmCo magnets. With years of experience, NBAEM specializes in creating customized Halbach arrays tailored to clients’ unique industrial needs in the U.S. and beyond.

NBAEM’s Expertise

- Wide range of magnetic materials suitable for Halbach arrays magnets

- Advanced magnetization technology for precise magnetic pole orientation

- Custom design capabilities for linear, circular, 2D, and 3D arrays

- Quality control meeting strict customer standards

Examples of Customized Halbach Array Magnets by NBAEM

| Application | Type of Halbach Array Magnets | Key Features |

|---|---|---|

| Electric motors | Circular rotor | Higher torque density, compact size |

| Magnetic levitation | Linear Halbach array | Strong magnetic field on one side |

| MRI machines | 2D Halbach array | Uniform magnetic flux concentration |

| Wind turbines | 3D Halbach array | Lightweight and efficient |

Benefits for Industrial Clients

- Improved performance with stronger, focused magnetic fields

- Reduced magnetic interference, enhancing reliability

- Cost-effective solutions with customized designs

- Faster turnaround with expert sourcing and production

- Support in integrating Halbach arrays into cutting-edge technology projects

NBAEM’s tailored Halbach arrays magnets help industries boost efficiency, reduce size and weight, and optimize magnetic use—making their solutions a solid choice for businesses demanding high-performance magnets.

Future Trends in Halbach Array Magnets Technology

Halbach arrays magnets are evolving quickly thanks to innovations in magnetic materials and array designs. New developments in magnets like advanced NdFeB blends and rare-earth alternatives are pushing field strength and temperature resistance higher. Designers are also creating more complex 2D and 3D Halbach configurations to better fit specific applications.

Market demand is booming, especially in China and other global regions where electric vehicles, wind energy, and industrial automation are growing fast. These applications benefit from the compact size and powerful magnetic fields Halbach arrays provide.

On the environmental side, there’s a big focus on energy efficiency and reducing material waste in manufacturing. Developing magnets that use fewer rare earth elements while keeping performance high is a priority. This shift helps reduce costs and the environmental footprint, aligning well with stricter regulations and the push for greener tech.

Leave A Comment