Is N55 Magnet Really the Strongest A Data Driven Breakdown

N55 magnet property

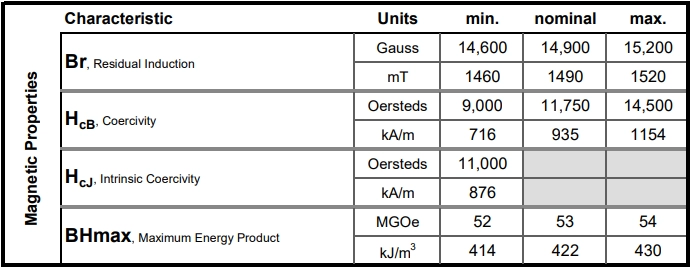

N55 is widely recognized as the strongest commercial neodymium magnet grade, topping out at about 55 MGOe (maximum energy product). This number basically measures how much magnetic energy the magnet can hold—the higher the MGOe, the stronger the magnet’s field. In practical terms, N55 magnets deliver impressive pull forces, making them ideal for applications that demand intense magnetic power in a compact size.

That said, there are theoretical grades like N64, which push beyond 55 MGOe. However, these are mostly experimental and not available for commercial use yet. When we compare N55 magnets to other types like Samarium Cobalt (SmCo) magnets or electromagnets, N55 usually stands out for raw magnetic strength, though SmCo offers much better heat resistance, and electromagnets provide adjustable power but require energy to operate.

Here’s a quick comparison to give you a clearer picture:

| Magnet Type | Max Energy Product (MGOe) | Max Operating Temp (°F) | Cost Level |

|---|---|---|---|

| N35 NdFeB | 35 | 176 | Low |

| N52 NdFeB | 52 | 176 | Medium |

| N55 NdFeB | 55 | 176 | High |

| Theoretical N64 | 64 | Unknown | Experimental |

| SmCo | 22 | 572 | High |

| Electromagnets | Variable | Variable | High/Ongoing Cost |

So, while N55 is the commercial ceiling in terms of strength for NdFeB magnets, it comes with trade-offs, especially around temperature limits and cost. But in the world of permanent rare-earth magnets, N55 remains the powerhouse many industries rely on.

N55 vs N52 The Battle of the Titans Which Wins for Your Needs

When it comes to neodymium magnet grades, N55 and N52 are often called the heavy hitters. Both pack serious punch, but which one fits your project best depends on a few key factors like strength, price, availability, and performance details such as magnetization and coercivity.

Strength and Magnetization

- N55 has a maximum energy product (BHmax) of about 55 MGOe, making it the strongest commercially available magnet right now.

- N52 follows closely with 52 MGOe, still very powerful but slightly less dense than N55.

Price and Availability

- N55 magnets cost more and are less widely available than N52 because of the stricter manufacturing demands.

- N52 magnets are more common in the US market and often easier to source quickly.

Performance Metrics

- Both have high magnetization levels and strong coercivity, meaning they resist demagnetization well.

- N55 may have a slight edge in magnetic strength but can be a bit more sensitive to temperature and mechanical stress.

How to Choose Between N55 and N52

Consider these points to decide which magnet grade suits your needs:

- Need Maximum Strength? Go with N55 for the strongest field in the smallest space.

- Tight Budget? N52 gives excellent performance with better cost efficiency.

- Space Constraints? N55 is denser, so perfect for compact designs needing power.

- Temperature and Durability? N52 is generally a bit tougher under heat and rough handling.

- Availability and Lead Time? N52 usually ships faster with more supplier options in the USA.

Real World Win: NBAEM Supplied N55 in EV Motors

A recent case with NBAEM, a leading Chinese neodymium magnet supplier, shows how N55 magnets help electric vehicle (EV) motors perform better. By using custom N55 discs, manufacturers gained higher torque and efficiency without increasing motor size. This directly improved driving range and power output—key for US EV makers aiming to deliver more miles and better performance.

In , if your project calls for the absolute strongest magnet and you can handle premium pricing and lead times, N55 is the way to go. For broader availability and solid power at a lower cost, N52 remains a reliable winner.

The Trade Offs of Ultimate Strength Limitations of N55 Magnets

N55 magnets pack serious power, but they come with some trade offs you should know. First, temperature is a big limit. N55 magnets have a max operating temp around 80 to 100°C. Push beyond that, and you risk demagnetization—meaning they lose strength permanently. This temperature vulnerability makes them tricky in high-heat environments.

Besides heat, N55 magnets are brittle. Drop or mishandle them, and they can crack or chip. Corrosion is another issue since NdFeB magnets can rust if not coated properly. These factors also drive up costs compared to lower-grade magnets like N52.

To get the most out of N55 magnets, consider these tips:

- Use high-temp variants or specially coated magnets for better durability

- Apply protective coatings (nickel, epoxy) to fight corrosion

- Pair N55 with temperature-tolerant materials in your design to avoid demagnetization risks

Remember, while N55 might top the charts in strength, it’s not always the best choice if your project needs high heat resistance or budget-friendly options. Strength isn’t everything, and weighing these pros and cons upfront will save you headaches later.

Real World Applications Where N55 Shines and Where It Doesn’t

N55 magnets are a game changer where strong magnetic pull and compact size matter most. You’ll find them powering sensors, MRI machines, compact motors, and aerospace actuators. Their dense magnetic fields make them perfect for high-precision, high-stakes uses where strength can’t be compromised.

That said, N55 magnets aren’t ideal everywhere. They struggle in high temperature environments because they can lose magnetism faster than some high-temp variants. Plus, for cost-sensitive products, the premium price of N55 might not make sense when lower-grade magnets could do the job.

Looking ahead, N55 is gaining traction in fast-growing sectors like renewable energy, wind turbines, and electric vehicles. Much of this momentum is driven by China’s leadership in rare earth mining and manufacturing—NBAEM stands out here by offering custom N55 discs and rings with quick turnaround times, making it easier for U.S. companies to get top-quality magnets fast.

If you need powerful, reliable magnets for advanced tech but want to keep lead times short, N55 from trusted suppliers like NBAEM is definitely worth a look.

How to Source and Handle N55 Magnets Like a Pro

When you’re looking to source N55 magnets, it’s smart to stick with ISO-certified suppliers to ensure consistent quality and reliability. China, particularly NBAEM, leads the market with a fully integrated supply chain, making it easier to get authentic, high-strength N55 magnets without extra hassle.

Handling N55 magnets needs caution—these super strong magnets can pinch skin if you’re not careful. Always wear gloves when working with them, keep magnets separated by spacers during storage, and use specialized tools if you need to machine or cut them.

Cost-wise, prices vary based on volume, shape, and any coatings like Ni-Cu-Ni or epoxy for corrosion resistance. Sample orders usually come at a premium but can help test fit and strength before committing to a full order.

To make life easier, reach out to NBAEM for samples and expert advice. They offer fast lead times and tailored solutions so you get the powerful N55 magnets you need without the usual headaches.

For more details on magnet strength and sourcing, check out NBAEM’s guide on strongest magnets.

Understanding Neodymium Magnet Grades The Basics of N Ratings

Neodymium magnets, known scientifically as neodymium-iron-boron (NdFeB) magnets, come in various grades that indicate their magnetic strength. Each grade is labeled with an “N” followed by a number, such as N35, N52, or N55. This number represents the magnet’s maximum energy product (BHmax) measured in mega-gauss Oersteds (MGOe), which quantifies how strong and dense the magnetic field is. Simply put, the higher the number, the more powerful the magnet.

Here’s a simple comparison to help visualize the differences between common grades:

| Grade | Maximum Energy Product (BHmax) MGOe | Relative Pull Strength | Relative Cost Level |

|---|---|---|---|

| N35 | 35 | Moderate | Low |

| N52 | 52 | Very High | Mid |

| N55 | 55 | Highest Commercially Available | High |

Several key factors influence a magnet’s strength beyond just the grade:

- Material Composition: The precise mix of neodymium, iron, and boron, along with trace additives.

- Manufacturing Process: Techniques like sintering, pressing, and heat treatment directly impact magnetic performance.

- Physical Properties: Size, shape, and magnetization direction also affect the usable magnetic field.

When it comes to sourcing high-grade N55 magnets, China plays a pivotal role. The country dominates rare-earth mining and refining, which underpin the quality and availability of premium N55 magnets worldwide. Trusted suppliers like NBAEM leverage this advantage to provide consistent, high-performance magnets suited for demanding commercial and industrial uses.

For a deeper dive into the science and strength comparison of magnets, you can also visit NBAEM’s resources on the subject here.

N55 magnets stand as the strongest commercially available neodymium magnets, hitting that 55 MGOe maximum energy product mark. For many businesses and industries, this means unmatched magnetic strength and reliability, delivering the best return on investment when you need top-tier performance in compact spaces. Whether you’re working on electric motors, sensors, or other high-demand applications, N55 offers that edge in power and efficiency.

Looking ahead, newer grades like N56 are on the horizon, promising slightly higher strength, but they’re not widely commercial yet. NBAEM is actively investing in R&D to bring these advanced magnets to market soon, alongside a strong focus on sustainable and ethical rare earth sourcing—important for customers prioritizing both performance and responsible supply chains.

If you’re considering N55 magnets for your projects, take advantage of NBAEM’s grade selector guide to find the perfect match for your needs. Reach out to NBAEM’s -friendly sales team to get samples, pricing, and expert advice—making your switch to super strong, reliable magnets hassle-free and efficient.

[…] dive into magnet strength and temperature durability, you can explore highly relevant info on the N55 magnet strength comparison and the materials that withstand high temperatures to better understand magnet performance in tough […]