What is the Use of a Magnetic Bar? A Comprehensive Guide to Industrial and Practical Applications

When we talk about maintaining product purity and protecting expensive machinery, the 자기 막대—often referred to in the industry as a magnetic filter rod—is the unsung hero of the production line. At its core, this is not just a simple magnet; it is a precision-engineered permanent magnet assembly designed to capture fine iron dust, metal chips, and “tramp” metal from free-flowing materials.

We manufacture these essential tools by encasing high-intensity 네오디뮴 (NdFeB) or Samarium Cobalt cores within a seamless, fully welded 304 or 316L stainless steel casing. This construction ensures that the magnetic circuit is both waterproof and durable enough for harsh industrial environments. Whether you are running a food processing plant requiring HACCP compliance or a plastics facility protecting injection molds, the primary use is clear: absolute ferrous contamination removal.

In this guide, I will walk you through exactly how we engineer these bars to achieve surface field strengths of up to 12,000 Gauss and how they serve as the critical defense line in sectors ranging from pharmaceuticals to heavy recycling.

Magnetic bar

Industrial Filtration and Separation: The Heavy Lifters

At NBAEM, we engineer magnetic filter rods to serve as the primary defense line in processing lines. These aren’t just simple metal tubes; they are high-intensity separators designed to pull damaging metal out of free-flowing materials. In industrial settings, purity is everything. Whether you are dealing with powders, granules, or liquids, a magnetic bar acts as a critical checkpoint that ensures product quality and protects expensive machinery downstream.

Removing Ferrous Contaminants in Hoppers and Chutes

The most common application we see for a hopper magnet or grid magnet assembly is right at the intake point. By installing these bars in chutes, hoppers, and ducts, we effectively capture tramp metal removal before it causes havoc.

- Gravity Feed: As material falls past the bar, the magnetic field grabs bolts, nuts, and fine iron dust.

- Liquid Lines: In pipeline applications, we use pipe magnet systems to filter liquids and slurries.

- Protection: This prevents metal from entering crushers, grinders, or injection molding machines, saving thousands in repair costs.

Key Industries: Food, Plastics, and Pharma Protection

Different sectors rely on industrial magnetic filtration for distinct reasons, but the goal remains the same: absolute purity.

- 식품 가공: We use 316L stainless steel casing to meet strict HACCP and food safety standards. This ensures no metal shavings end up in the final consumable product.

- Plastics: A single metal fragment can destroy a precision injection mold. Our bars catch these contaminants to keep production running smoothly.

- 제약 산업: High-purity requirements demand the strongest Neodymium (NdFeB) bar magnets to capture even weakly magnetic stainless steel particles.

How Magnetic Flux Rings Trap Metal Debris

The magic happens inside the tube. We utilize a high-density permanent magnet assembly—typically Neodymium or Samarium Cobalt—arranged to create concentrated magnetic fields. This arrangement generates specific “flux rings” along the length of the bar.

When ferrous debris passes through this 자기 플럭스 밀도, it is instantly drawn to the areas of highest intensity (the poles). The captured metal migrates to the underside of the bar, preventing the flow of material from washing it back into the stream. To understand the power source behind this capture efficiency, you can look at our 희토류 자석 가이드, which explains the core materials we use to achieve surface field strengths up to 12,000 Gauss. This ensures that once a particle is trapped, it stays trapped until cleaning.

Precast Concrete and Construction Magic

While often associated with filtration, the powerful permanent magnet assembly technology inside our bars plays a critical role in the precast concrete industry. We utilize high-intensity 네오디뮴 (NdFeB) cores encased in durable steel to revolutionize how concrete forms are secured and shaped, moving away from destructive traditional methods.

Magnetic Chamfer Strips for Perfect Edges

Achieving precise beveled corners on concrete blocks requires absolute stability. A magnetic chamfer strip snaps directly onto the steel casting bed, eliminating the need for screwing, bolting, or welding. This application relies on the same high-intensity magnetic flux principles we engineer into our filter rods, ensuring the strip remains immovable during the pouring and vibrating process. This results in clean, leak-free edges every time.

Shuttering Magnets: Holding Rails Without Welding

Traditional formwork often damages expensive steel tables through repeated drilling and welding. Shuttering magnets solve this by using a powerful magnetic block to clamp side rails firmly in place. These assemblies protect the formwork integrity and allow for rapid adjustments. Our engineering team provides customized service to adapt these high-strength magnetic solutions for specific structural requirements.

Benefits: Speed, Reusability, and Formwork Protection

Switching to magnetic fixation systems offers clear operational advantages over mechanical fastening.

| 특징 | 혜택 |

|---|---|

| Zero Welding | Extends the lifespan of steel casting tables by preventing surface damage. |

| High Reusability | Durable steel casing (SUS304/316L) ensures tools last for years. |

| Rapid Setup | Reduces labor time by simply placing and engaging the magnet. |

| Leak Prevention | Strong holding force prevents concrete from bleeding through gaps. |

Manufacturing and Automation Roles

Beyond simple filtration, we engineer magnetic bars to serve as critical components in modern automated production lines. Their consistent magnetic field and durability make them ideal for non-contact sensing and material handling tasks where reliability is non-negotiable.

Proximity Detection with Hall Effect Sensors

In automated machinery, precision is everything. Our magnetic bars often function as the trigger element for Hall effect sensor applications. Because these sensors rely on detecting magnetic fields to determine position or speed, the stability of the magnet is crucial.

- Non-Contact Switching: Unlike mechanical switches that wear out, a permanent magnet assembly triggers sensors without physical contact, extending the lifespan of the equipment.

- Harsh Environments: Magnetic triggers work perfectly in dirty or oily environments where optical sensors often fail.

- Consistent Signal: We utilize high-grade cores—understanding NdFeB 자석 제작 방법 material allows us to guarantee a stable flux density that prevents signal drift over time.

Stabilizing Parts on Vertical Conveyor Systems

Moving ferrous parts against gravity requires a secure hold. We design magnetic rails and bar assemblies that sit behind conveyor belts to stabilize products during transport.

- Vertical Transport: Magnets hold steel cans, lids, or stamped parts firmly against the belt, allowing for vertical or inverted movement without slippage.

- Vibration Control: The magnetic field dampens vibration, keeping parts aligned for the next stage of processing, such as painting or filling.

- Zero Energy Cost: Since these are permanent magnets, they provide constant holding force without requiring electricity or generating heat.

Laboratory and Chemical Processing Uses

In the world of chemical engineering and laboratory research, purity is everything. We rely on magnetic bars not just for holding things in place, but for maintaining the integrity of chemical reactions and ensuring the final product is free from contaminants.

Magnetic Stir Bars for Sterile Mixing

For laboratory applications, the magnetic stir bar is a staple tool. These are small magnetic rods, typically encapsulated in chemically inert materials like PTFE (Teflon), placed directly into a flask or beaker. By utilizing a rotating magnetic field from a base plate, the bar spins rapidly to mix solutions without any physical contact from an external rod. This allows for sterile mixing inside closed containers, preventing outside contamination and protecting technicians from hazardous fumes. While these are smaller than our industrial filtration rods, they rely on the same high-quality permanent magnet cores to maintain coupling with the drive motor.

Liquid Line Separation in Chemical Plants

Scaling up to industrial processing, we use heavy-duty magnetic filter rods to purify liquid product streams. In chemical plants, fluids often flow through pipelines where tramp metal removal is critical to protect pumps and ensure product purity.

- 부식 저항성: We engineer these bars using 316L stainless steel casing. This grade provides superior resistance to corrosive chemicals compared to standard 304 steel, ensuring the bar doesn’t degrade in harsh acidic or alkaline environments.

- High-Temperature Handling: Chemical reactions often generate significant heat. For these lines, we utilize 희토류 자석 가이드 to select High-temperature SmCo magnets (Samarium Cobalt), which maintain their magnetic field strength even at temperatures up to 350°C.

- Installation Flexibility: These rods are frequently integrated into pipe magnet assemblies or arranged as grid magnets within hoppers and liquid chutes. This setup forces the liquid to flow around the bars, ensuring that even the finest ferrous particles are trapped by the high-intensity magnetic flux before the product moves to the next stage.

Everyday Workshop and Safety Hacks

Organizing Tools with Heavy-Duty Strips

Beyond complex industrial machinery, a simple magnetic bar is one of the most effective ways to declutter a workspace. We often see our high-intensity permanent magnet assemblies mounted on workshop walls to securely hold wrenches, screwdrivers, and drill bits. Unlike standard consumer-grade strips, industrial-grade bars use powerful Neodymium cores that prevent heavy tools from slipping. This setup keeps critical equipment visible and within arm’s reach, improving workflow efficiency. The consistent holding force relies heavily on the quality of Neodymium magnets used inside the tube, ensuring tools stay in place until you need them.

Magnetic Sweepers for FOD Control and Safety

Safety is paramount in any manufacturing or construction environment. Magnetic bars serve as the core component in magnetic sweeping tools designed to clear floors of dangerous metal debris. By attaching a robust magnetic rod to a wheeled handle or forklift mount, operators can quickly pick up nails, screws, and metal shavings that would otherwise cause tire punctures or tripping hazards. This process, often referred to as FOD (Foreign Object Debris) control, relies on the strong magnetic flux density of the bar to snap up ferrous items instantly. Our 304 or 316L stainless steel casing protects the internal magnets from impact, making these sweepers durable enough for harsh garage and warehouse conditions.

How to Choose the Right Magnetic Bar

Selecting the correct magnetic filter rod isn’t just about picking a size; it’s about matching the magnetic intensity and durability to your specific processing environment. We engineer our bars to meet diverse industrial needs, from food safety to heavy mining. Here is how to navigate the specifications.

Material Battle: Neodymium vs. Ferrite vs. SmCo

The core material inside the tube determines the magnetic strength and temperature resilience.

- Neodymium (NdFeB) Bar Magnets: These are the industry standard for high-intensity filtration. They offer the strongest magnetic field, making them ideal for capturing fine ferrous dust and weak magnetic particles in food and plastic processing.

- 사마륨 코발트 (SmCo): When your production line exceeds standard operating temperatures (above 150°C), standard magnets lose strength. For these extreme environments, we utilize high-performance SmCo magnets which maintain stability up to 350°C.

- 페라이트: While less common in high-precision bars due to lower strength, they are cost-effective for capturing large “tramp” iron where fine particle filtration isn’t critical.

| 재료 | 자기장 강도 | Max Temp | Best Application |

|---|---|---|---|

| 네오디뮴 (NdFeB) | Very High (up to 12,000 Gauss) | 80°C – 150°C | Fine powder, food, pharma |

| SmCo | 높음 | Up to 350°C | High-heat liquids, molding |

| 페라이트 | Low/Medium | 최대 250°C | Large tramp metal removal |

Casing Matters: 304 vs. 316L Stainless Steel

The durability of a permanent magnet assembly relies heavily on its outer shell. We use laser welding technology to ensure these tubes are completely sealed and waterproof.

- SUS304 Stainless Steel: The go-to choice for general industrial applications. It provides excellent durability and wear resistance for plastics, ceramics, and recycling industries.

- SUS316L Stainless Steel: Mandatory for food, beverage, and pharmaceutical lines. This 316L stainless steel casing offers superior corrosion resistance and meets strict hygiene standards (HACCP), preventing contamination in acidic or saline environments.

Understanding Gauss Ratings for Filtration

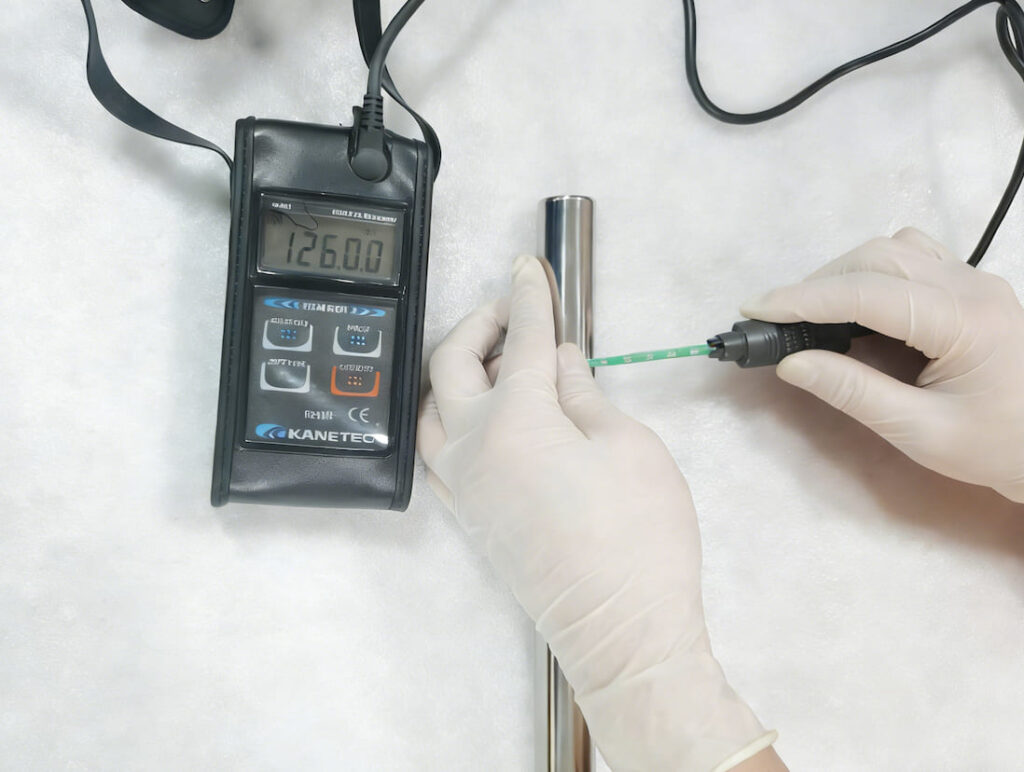

magnetic bar surface gauss magnetic flux density

자기 플럭스 밀도, measured in Gauss, tells you how deep the magnetic field penetrates and how small a particle it can trap.

- 6,000 – 8,000 Gauss: Standard strength. Effective for capturing nails, bolts, and larger metal chips.

- 10,000 – 12,000 Gauss: High intensity. Required for trapping microscopic paramagnetic particles and stainless steel wear dust.

Choosing the right Gauss rating ensures you aren’t overspending on unnecessary power or under-protecting your product stream.

Maintenance and Cleaning Best Practices

To ensure your magnetic filter rod continues to capture fine iron particles effectively, a strict cleaning schedule is essential. When ferrous contamination removal is successful, metal buildup on the bar’s surface can eventually bridge the magnetic circuit, reducing the effective field strength. We recommend establishing a routine based on the volume of contamination in your material flow to maintain that peak 12,000 Gauss performance. Regular inspection during cleaning is also the perfect time to understand how long permanent magnets last in your specific operating conditions.

Manual Wiping vs. Easy-Clean Sleeve Systems

Choosing the right cleaning method depends on your throughput and safety requirements.

- Manual Cleaning: This is the standard approach for basic tube magnets. Operators remove the bar and manually wipe the captured metal toward the non-magnetic ends using a cloth or gloved hand. Since our Neodymium magnets are extremely powerful, the metal debris holds on tightly. Always use heavy-duty gloves to prevent cuts from sharp metal shavings.

- Easy-Clean Sleeve Systems: For automated or high-volume lines, we engineer easy-clean systems. The magnetic bar is housed inside a secondary stainless steel sleeve. To clean it, you simply pull the magnetic core out of the sleeve. Without the magnetic field holding them, the contaminants instantly fall off. This method is faster, safer for operators, and reduces wear on the 316L stainless steel casing.

Frequently Asked Questions About Magnetic Bars

Can magnetic bars lose their strength over time?

Under normal operating conditions, high-quality permanent magnet assemblies retain their power almost indefinitely. They do not “run out” of energy like a battery. However, exposure to extreme heat or physical shock can reduce magnetic flux density. Standard Neodymium (NdFeB) bar magnets typically operate safely up to 80°C. For applications involving higher heat, we recommend using Samarium Cobalt magnet data sheet specifications to select high-temperature SmCo magnets, which can withstand up to 350°C without significant demagnetization.

What is the difference between a magnetic bar and a tube magnet?

In the industry, these terms are often used interchangeably. Technically, the “tube” refers to the protective stainless steel shell, while the 자기 막대 (or magnetic filter rod) is the complete finished product containing the magnetic core. Whether you call it a bar, rod, or tube magnet, the function remains the same: capturing ferrous debris. We manufacture these bars with custom diameters and lengths to fit specific hopper magnet or grid configurations.

Are magnetic bars safe for food processing?

Yes, but the construction quality matters. For food grade magnetic separation, we strictly utilize 316L stainless steel casing. This material offers superior corrosion resistance and hygiene compared to standard 304 steel. Furthermore, our manufacturing process uses advanced laser welding to ensure the bars are fully waterproof and seamless. This prevents liquid ingress and eliminates crevices where bacteria could hide, meeting strict HACCP standards for ferrous contamination removal in food lines.

댓글 남기기