What Are Magnet Grades

Magnet grades are a way to classify the strength and material properties of permanent magnets. For example, common neodymium magnet grades include N35, N42, and N52, where the “N” stands for neodymium, and the number represents the magnet’s maximum energy product (BHmax) — a measure of how much magnetic energy the material can store. In general, higher numbers mean stronger magnets, assuming the same size and shape.

The grade not only reflects magnetic strength but also material composition and performance characteristics, including temperature tolerance and resistance to demagnetization.

Here’s a quick overview of popular magnet types and their typical grades:

- Neodymium (NdFeB) – The strongest commercially available permanent magnets; grades typically range from N35 to N52.

- Ferrite (Ceramic) – Cost-effective and corrosion-resistant; grades such as C5 or C8.

- Alnico – Excellent temperature stability, good for high-heat applications; grades like Alnico 5 or Alnico 8.

- Samarium Cobalt (SmCo) – High strength with superior temperature and corrosion resistance; grades commonly from SmCo 16 to SmCo 32.

Understanding magnet grades helps in selecting the right material for your application — whether you need maximum strength, high heat resistance, cost efficiency, or durability in harsh environments.

Understanding Pull Force What It Means and Why It Matters

Pull force is the amount of weight a magnet can hold before it detaches from a steel surface. It’s usually measured in pounds or kilograms. This is one of the most practical ways to compare magnet strength because it reflects real holding power rather than just lab measurements.

Pull force depends on a few main factors:

- Magnet size – Larger magnets generally have more holding power.

- Magnet grade (N number) – Higher grades like N52 can produce more pull force compared to lower grades like N35, assuming the same size.

- Contact surface – Smooth, clean steel gives the highest pull force. Any gap, paint, or rust will lower it.

In industries, pull force ratings matter for jobs like lifting heavy steel sheets, securing tools, or holding fixtures in place. For consumer use, it’s equally important—for example, mounting objects, building magnetic closures, or DIY home improvement projects.

When you check magnet specs, remember: the stated pull force is typically measured under ideal lab conditions. In real-world use, expect actual holding power to be less due to surface conditions or extra spacing. If your project needs a specific holding strength, use the pull force rating as a guide and add a safety margin.

Gauss Magnet Strength The Magnetic Field Measurement

Gauss is a unit that tells us how strong a magnetic field is at a specific point. When we measure magnet strength, we often look at two main values:

- Surface Gauss – the magnetic field measured right on the surface of the magnet with a gauss meter.

- Residual Flux Density (Br) – the maximum magnetic energy the material can hold, measured in kilogauss (kG) or tesla (T) in a lab setting.

Surface gauss is what you’ll see in real-world readings, while Br is a material property used for comparing grades during manufacturing.

Why Gauss Matters

Gauss readings help you:

- Compare magnet strength before purchase

- Match the right magnet to your application

- Estimate holding force along with size and grade

This is especially important for industrial uses, electronics, motors, and magnetic sensors where field strength directly impacts performance.

Typical Surface Gauss by Magnet Type

| Magnet Type | Common Grade Range | Approx. Surface Gauss* |

|---|---|---|

| Neodymium | N35 – N52 | 2,000 – 6,000 G |

| Ferrite (Ceramic) | C5 – C8 | 1,500 – 3,900 G |

| Samarium Cobalt | 18 – 30 | 2,000 – 5,000 G |

| Alnico | 2 – 9 | 800 – 1,200 G |

*Surface gauss varies by size, shape, and pole arrangement.

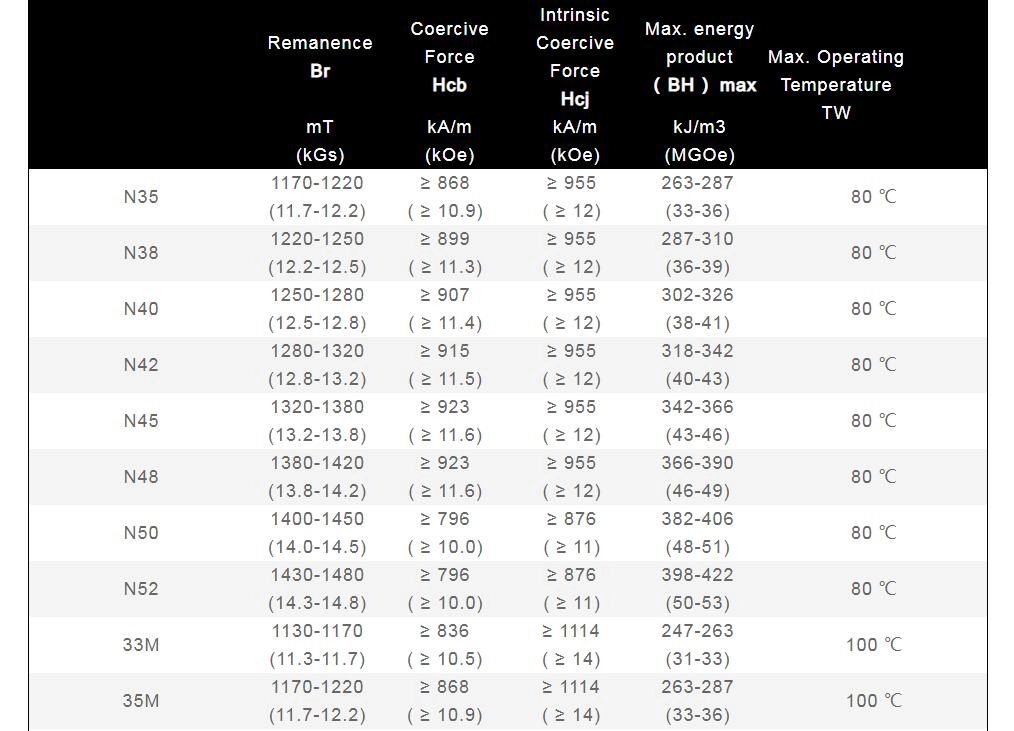

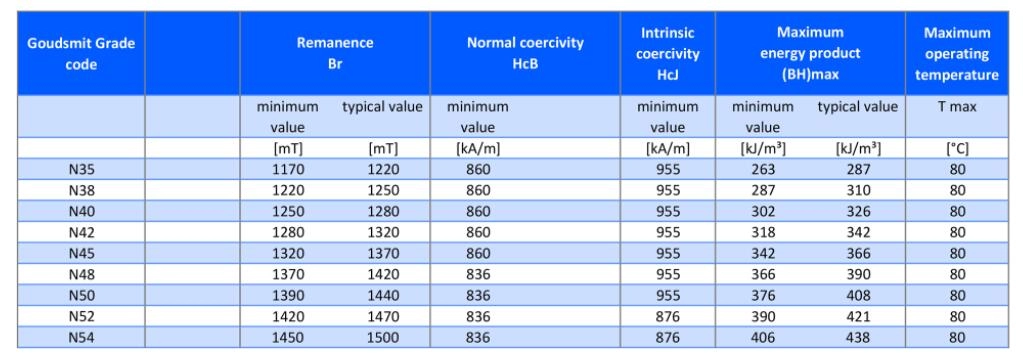

Decoding N Numbers What They Signify

When you shop for neodymium magnets, you’ll often see grades like N35, N42, N52. These N numbers tell you how strong the magnet material is. The “N” stands for neodymium, and the number refers to the maximum energy product (BHmax) — basically, how much magnetic energy the material can store. Higher numbers mean stronger potential pull, assuming the same size and shape.

For example:

- N35 is a more cost-effective grade for general use.

- N42 offers balanced strength and price.

- N52 is one of the strongest grades in standard production — ideal for when you need max strength in a small space.

The N number also influences performance:

- Pull Power – Higher N grades deliver stronger pull forces for the same magnet size.

- Temperature Resistance – Standard N magnets start losing strength above 80°C (176°F). For higher heat, you need special high-temp grades like N42SH or N35EH.

- Durability – The coating (nickel, epoxy, etc.) protects against corrosion, not the N grade itself — but higher-grade magnets should still be handled carefully because they are brittle.

Here’s a quick look at common N grades and what they mean:

| Grade | BHmax (MGOe) | Relative Strength | Typical Use |

|---|---|---|---|

| N35 | 33–35 | Standard | Crafts, light fixtures |

| N42 | 40–42 | Strong | Tools, consumer products |

| N48 | 46–48 | Very strong | Motors, industrial equipment |

| N52 | 50–53 | Maximum standard | Magnetic clamps, compact designs |

Understanding N numbers helps you match the right neodymium magnet grade to your pull force needs, working temperature, and application. Choosing the right one ensures you get performance without overspending.

How Magnet Grade Impacts Performance Real World Applications

Magnet grade makes a big difference in how a magnet performs, especially when it comes to strength, durability, and suitability for specific jobs. In the U.S., different industries pick grades based on performance needs and operating conditions.

For example:

- Motors and Generators – High-grade neodymium like N52 is often used for compact designs that require maximum torque in a small space.

- Sensors and Automation – Lower grades like N35 or N38 are enough for precise sensing without being too strong to affect nearby components.

- Magnetic Separators – Industrial separators may use N42–N50 for strong pull force to remove metal contaminants on conveyor belts.

- Electronics – Devices like speakers, hard drives, and wireless chargers often use customized N grades for efficiency and size constraints.

- DIY and Hobby Projects – Makers might pick N35 or N42 for cost-effectiveness when extreme pull isn’t necessary.

Matching the magnet grade to the application is key. A higher N number isn’t always better—too strong can cause handling issues, pull in unwanted items, or even damage equipment. The right grade balances pull force, gauss strength, temperature resistance, and cost for the job at hand.

Other Factors Affecting Magnet Strength and Performance

Magnet grade and type matter, but they’re only part of the story. A few other factors play a big role in how strong a magnet will actually be in real-world use.

1. Size and Shape

- Bigger magnets generally have more pull force because they have more material producing the field.

- Shape affects how the field is distributed. For example, a thin disc won’t pull the same way as a thick block, even if they’re the same grade.

2. Coating

- Coatings (like nickel, epoxy, or rubber) protect magnets from rust and physical wear, especially neodymium which can corrode easily.

- While the coating doesn’t increase magnetic strength, it can help maintain performance over time by preventing damage.

3. Temperature Ratings

- Every magnet has a maximum operating temperature. When it gets too hot, it can lose strength—sometimes permanently.

- Higher grades don’t always mean higher heat resistance. For example, standard N neodymium grades start losing power at around 80°C (176°F), but high-temp grades like N35SH can handle up to 150°C (302°F).

4. Environmental Conditions and Demagnetization Risks

- Strong opposing magnetic fields, heat, or heavy mechanical stress can cause a magnet to lose some or all of its magnetism.

- For outdoor use or exposure to moisture, weatherproof coatings or corrosion-resistant materials like samarium cobalt are better choices.

Keeping these factors in mind when selecting a magnet can save you from buying the wrong type for your project—whether it’s for industrial machinery, hobby builds, or custom fixtures.

Why Choose NBAEM Quality Magnetic Materials and Expert Guidance

When you’re dealing with magnets, the right grade, pull force, and gauss rating make all the difference. NBAEM offers a full range of magnetic materials – from neodymium (N35–N52) to ferrite, alnico, and samarium cobalt, in various shapes, sizes, and coatings to suit different applications.

Wide Product Range by Grade and Type

We stock magnets for light-duty consumer products all the way to heavy-duty industrial and engineering use. Options include:

- Neodymium magnets – high pull force, compact size

- Ferrite magnets – cost-effective, corrosion-resistant

- Alnico magnets – excellent temperature stability

- Samarium cobalt – high strength, extreme temperature resistance

| Magnet Type | Typical Grades | Key Benefits |

|---|---|---|

| Neodymium | N35–N52 | Highest pull force, small size |

| Ferrite | Y30–Y35 | Low cost, rustproof |

| Alnico | Alnico 5–8 | High temp stability |

| Samarium Cobalt | 18–32 MGOe | Heat & corrosion resistance |

Quality Control and Customization

NBAEM places heavy focus on tight tolerance control and consistent magnetic strength. Every batch is tested for pull force and gauss to meet spec. We also offer custom shapes, sizes, and coatings so your magnet is ready for your real-world application, whether it’s for a motor, sensor, magnetic separator, or DIY project.

Expert Guidance for Choosing the Right Magnet

Getting magnets right isn’t just about picking the highest N number. We work with you to match:

- Magnet grade to strength and cost

- Pull force to your load or holding needs

- Gauss levels to the precision your job requires

- Coating and shape to operating environment and durability

With NBAEM, you’re not guessing – you get materials tested, graded, and ready to perform exactly as you need.

Frequently Asked Questions FAQs

What does an N number indicate about strength

The N number tells you the grade of a neodymium magnet and directly relates to its maximum energy product (BHmax). A higher N number means the magnet can store more magnetic energy. For example, N35 is strong, but N52 delivers more power in the same size. Keep in mind that the number doesn’t mean physical size—two magnets of different grades but the same size can have very different strengths.

Relationship between pull force magnet size and grade

Pull force depends on both the grade and the physical dimensions of the magnet. Large magnets with high N grades produce the most pull. For example:

- A small N52 disc can have more pull force than a larger N35 disc.

- Doubling the size and increasing the grade can multiply pull force significantly.

When choosing, match the pull force to your application—too much force can make handling or removal difficult.

Using gauss measurement to compare magnets

Gauss measures magnetic field strength at the surface. A gauss meter gives a direct reading you can use for comparisons. Just note:

- Higher grades usually show higher surface gauss on the same size magnet.

- Shape, coating, and measurement distance affect readings.

If you’re comparing magnets for a project, measure them the same way for accurate results.

Impact of temperature and coating on magnet performance

Heat and environment can change a magnet’s performance:

- Many high grades like N52 lose strength faster under high temperatures.

- For higher heat resistance, look for special grades (e.g., N42SH or N35EH).

- Coatings like nickel-copper-nickel or epoxy protect against rust and chipping, especially in outdoor or humid settings.

Choosing the right temperature rating and coating extends magnet life and keeps performance stable.

Leave A Comment