NBAEM: Reliable Magnetic Materials for Your Innovation

Delivering premium magnetic solutions with precision and expertise, powering industries across the globe.

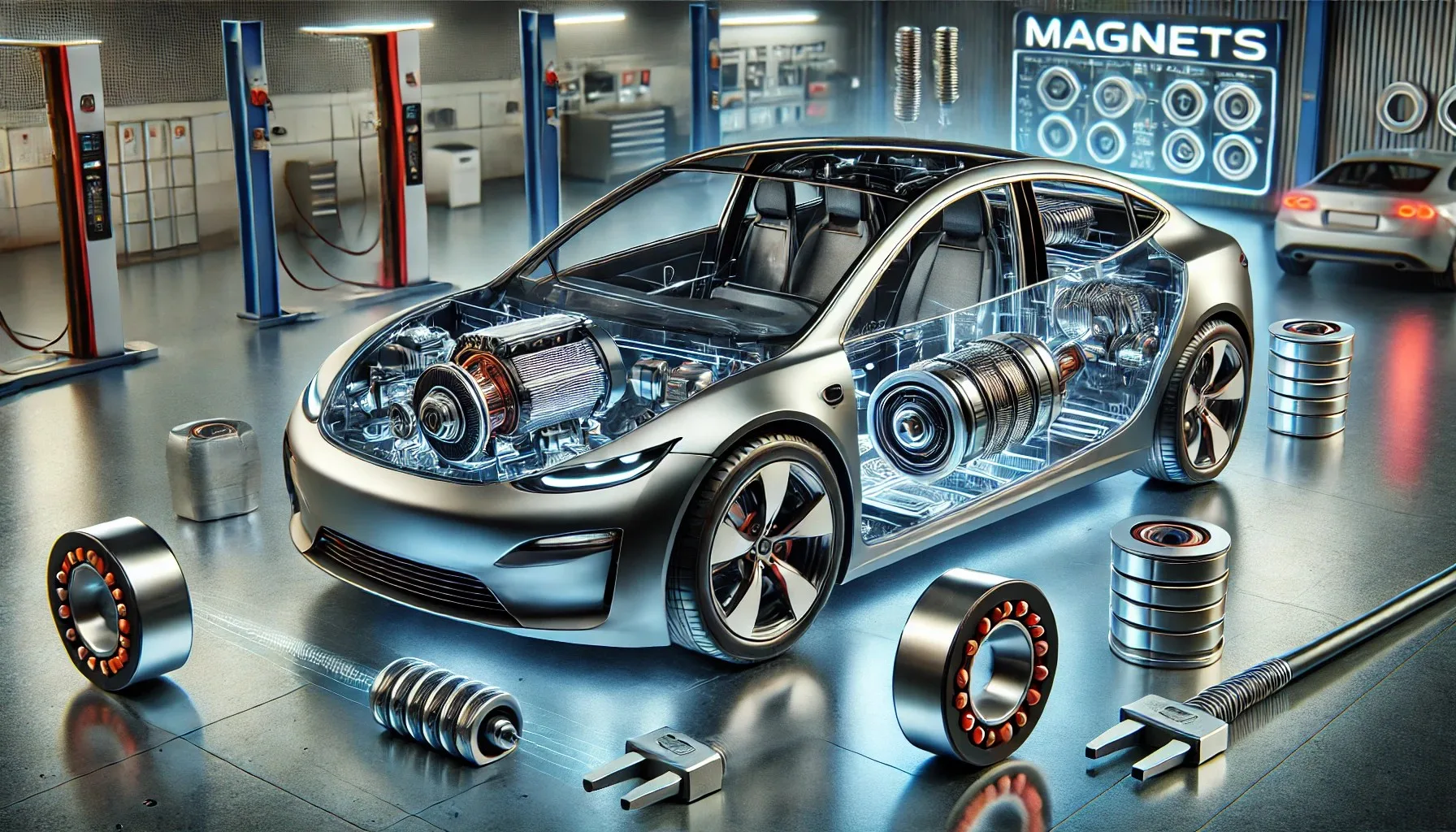

Explore Our ProductsPremium Magnetic Materials for Electric Vehicles

NBAEM delivers high-quality magnetic components designed to power innovation and performance across global markets.

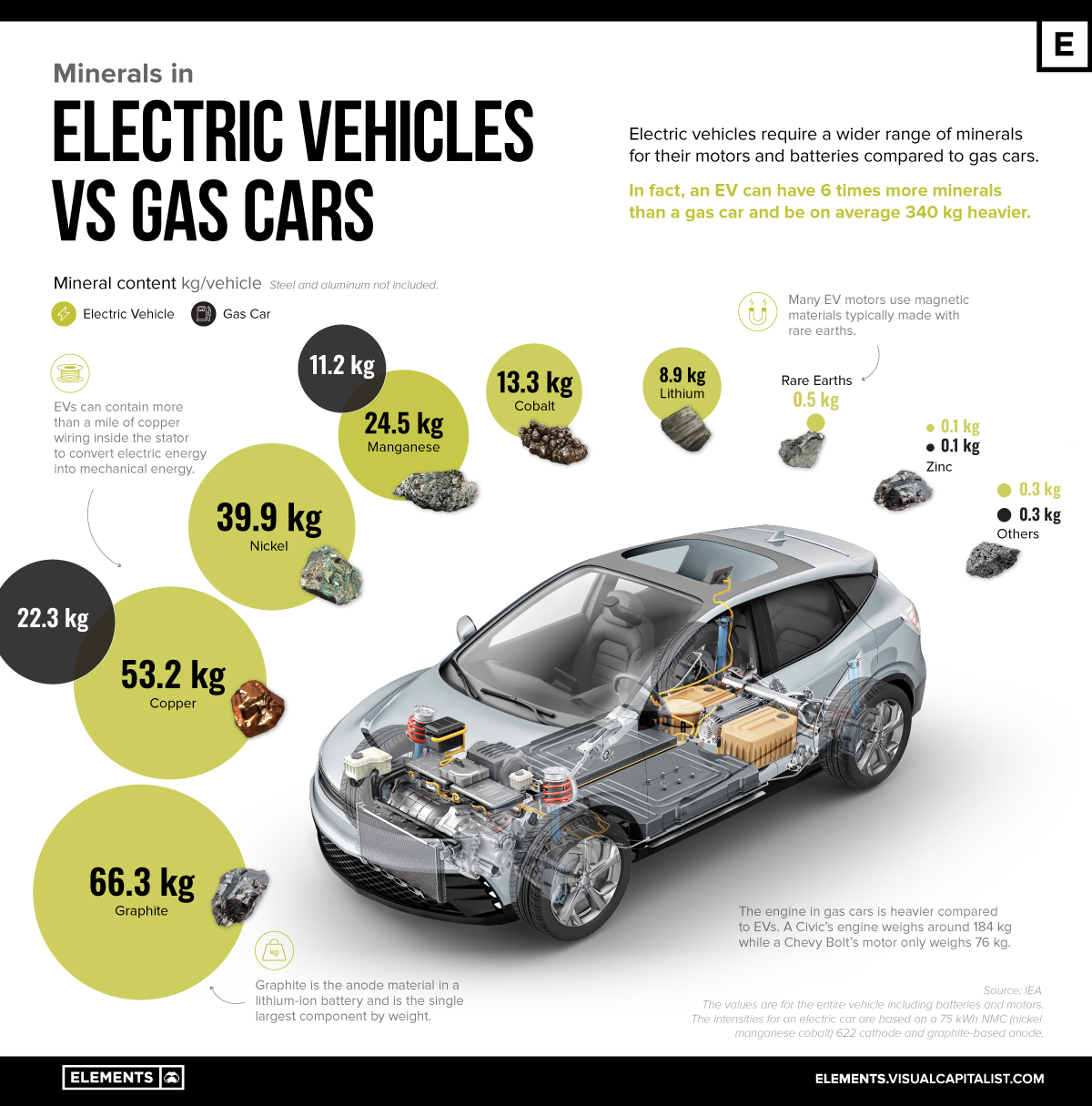

Types of Magnets Used in New Energy Vehicles

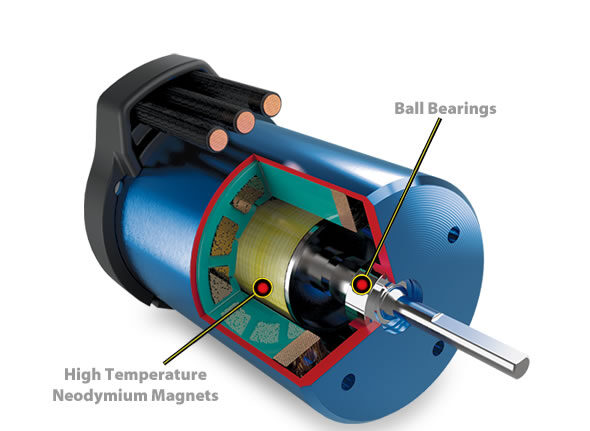

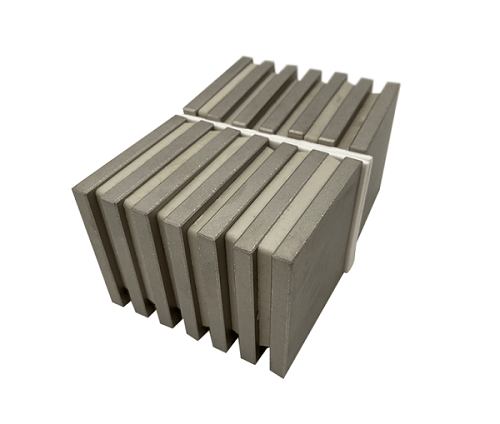

Neodymium Iron Boron (NdFeB) Magnets

NBAEM’s Neodymium Iron Boron (NdFeB) magnets are a cornerstone in the advancement of new energy vehicles. Renowned for their exceptional magnetic strength, NdFeB magnets enable high-performance electric motors that are compact, lightweight, and energy-efficient.

Key Features

- High magnetic energy product ensuring superior power density

- Excellent thermal stability with optimized temperature resistance

- Corrosion-resistant coatings to enhance durability in harsh environments

- Precisely engineered for automotive-grade reliability and safety

Automotive Applications

- Electric traction motors delivering high torque and efficiency

- Battery cooling systems with magnetic sensors for temperature monitoring

- Regenerative braking systems optimizing energy recovery

- Steering and stability control components enhancing driving precision

Samarium Cobalt (SmCo) Magnets

Samarium Cobalt magnets are a type of rare-earth magnet prized for their exceptional thermal stability and corrosion resistance. These characteristics make SmCo magnets ideal for use in electric motors and generators within new energy vehicles where high performance under varying temperatures is critical.

Unlike other magnet types, SmCo magnets can maintain their magnetic strength at temperatures up to 350°C, ensuring reliability and efficiency in demanding automotive environments.

At NBAEM, we specialize in providing premium SmCo magnets tailored specifically for the next generation of electric vehicles, ensuring high durability and sustainable performance.

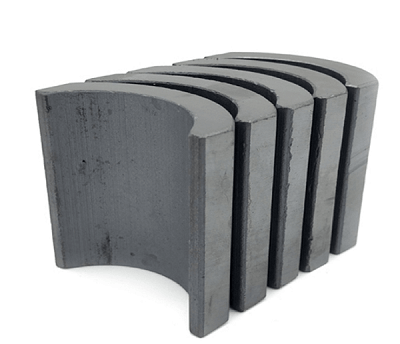

Ferrite Magnets(Ceramic Magnets): Cost-effective & Reliable

Ferrite magnets stand out as the most cost-effective option in new energy vehicle applications. Their robust design and magnetic performance make them ideal for sensor technology, powering essential components with reliability and efficiency.

Due to their resistance to corrosion and stable thermal properties, ferrite magnets ensure durability in demanding automotive environments. NBAEM delivers high-quality ferrite magnets tailored for cutting-edge electric vehicle solutions.

Contact NBAEMMagnets‘ Function in New Energy Car

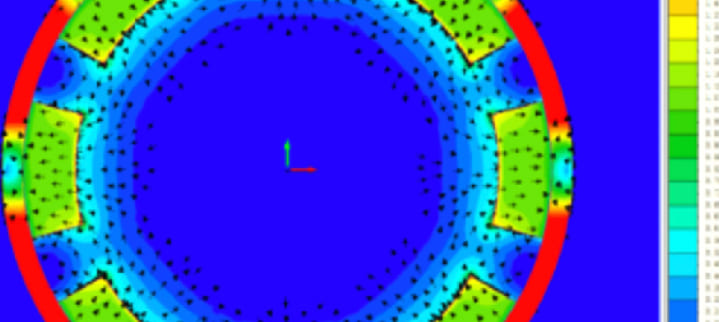

Exploring the impact of NdFeB and SmCo magnets in electric motors on torque efficiency and driving range.

Magnet Technology’s Impact on New Energy Vehicles

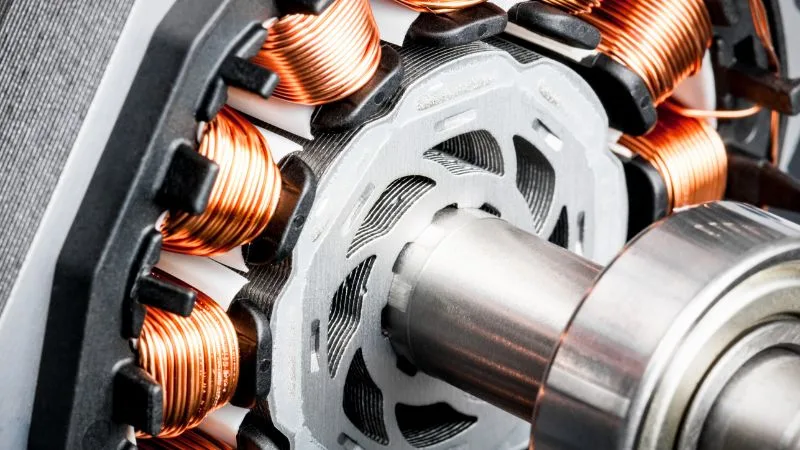

Integrating NdFeB and SmCo magnets in electric motors plays a vital role in current and future new energy vehicles, improving torque efficiency, reliability, and driving range. NBAEM is committed to advancing magnetic materials that shape the evolution of electric mobility.

NdFeB Magnets: Boosting Torque Efficiency

NBAEM supplies premium NdFeB magnets engineered to maximize performance in harsh operating conditions, ensuring sustained torque and reliability.

Neodymium Iron Boron (NdFeB) magnets, known for their high magnetic strength, significantly improve torque output in electric motors. Their compact size allows more powerful motors without increasing weight, enhancing vehicle acceleration and efficiency.

SmCo Magnets: Enhancing Range Through Thermal Stability

Samarium Cobalt (SmCo) magnets offer excellent thermal stability and corrosion resistance, crucial for high-performance electric motors operating under extreme temperatures. This stability helps maintain consistent torque, improving overall energy use and contributing to extended vehicle range.

NBAEM's SmCo magnets are optimized for durability and performance, ensuring electric motors perform efficiently throughout their lifespan.

Precision Sensors Powered by Ferrite Magnets

Ferrite magnets provide an ideal solution for sensors in new energy vehicles due to their cost-effectiveness and thermal stability. Their magnetic properties enable highly precise detection of position, speed, and current, ensuring enhanced reliability and safety.

High-Quality Actuators with Composite Magnets

Composite magnets combine different magnetic materials to optimize strength and efficiency in actuators. This results in faster response times, reduced energy consumption, and durable performance, vital for electric braking systems and throttle controls.

Provided by NBAEM, Your Trusted Magnetic Material Supplier

Optimizing Reliability in New Energy Vehicle Components

The integration of ferrite and composite magnets improves both durability and operational precision, critical for the harsh environments electric vehicles function in. These magnets sustain performance under vibration and temperature fluctuations, reducing maintenance costs.

Sustainability and Efficiency with Magnetic Solutions

Using ferrite and composite magnets supports sustainable manufacturing practices by minimizing rare earth metal dependency while maintaining high functionality, contributing to eco-friendly new energy vehicle production.

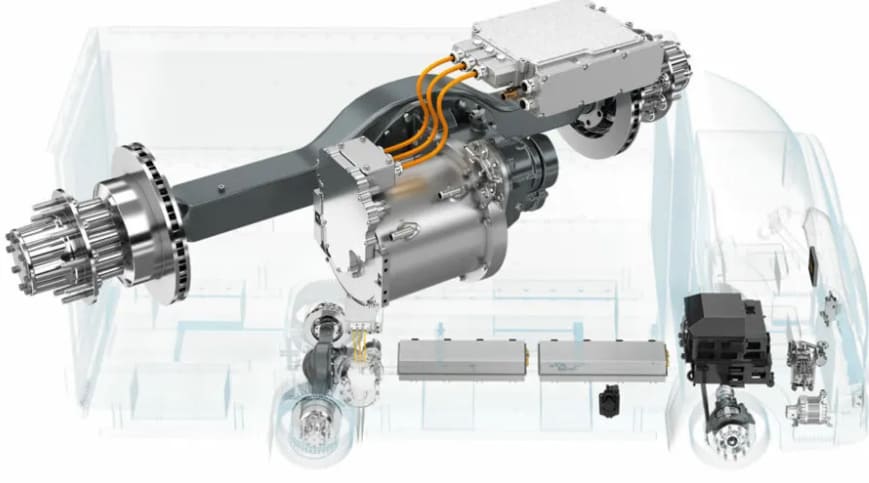

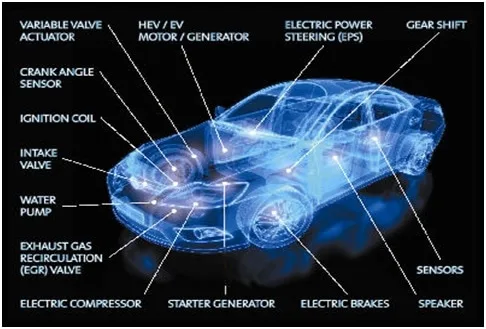

Specific Applications of Magnets in New Energy Vehicles

At NBAEM, we specialize in high-performance magnetic materials crucial for advancing New Energy Vehicle technologies. Magnets play vital roles beyond electric motors, powering essential systems like braking, HVAC units, and electric modules with precision and efficiency.

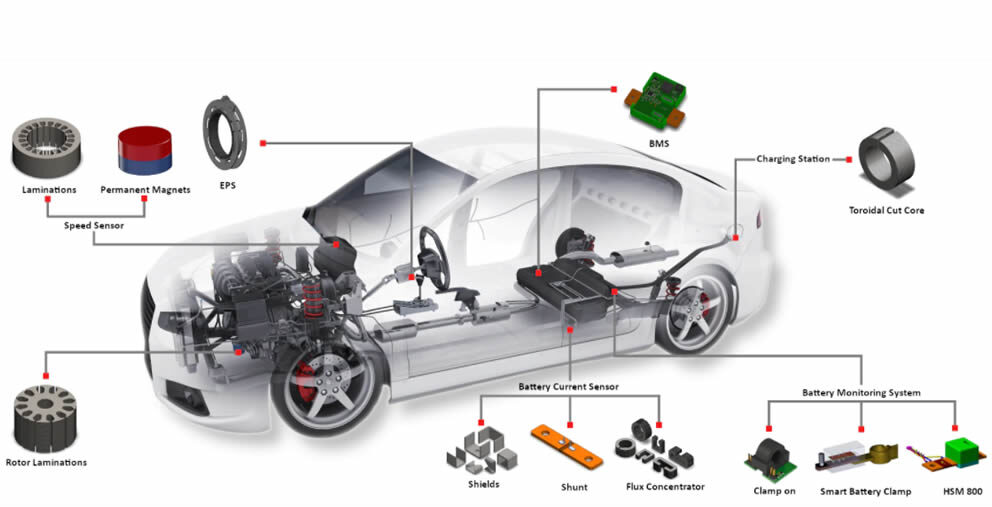

Electric Motors

Driving Motors: Permanent magnets, especially neodymium magnets, are essential in brushless DC motors that power the wheels. They provide strong magnetic fields for efficient motor torque and speed control. Auxiliary Motors: Smaller motors handling functions like cooling fans or power steering also use magnets to run smoothly and quietly

Battery Systems and Management

Magnets help in battery monitoring and management systems by working with sensors to ensure stable performance and safety throughout battery life.

Sensors and Actuators

Advanced magnetic sensors and modules enhance safety and performance by monitoring vehicle conditions and enabling precise control.

Regenerative Braking Systems

Rare earth magnets play a key role in regenerative braking. They help convert kinetic energy into electrical energy during braking, boosting overall vehicle efficiency.

Charging Modules

Wired Charging: Magnets contribute to precise alignment and connection in charging ports. Wireless Charging: Magnets create magnetic fields that transfer energy wirelessly from chargers to the car, making charging hassle-free and efficient.

Other Auxiliary Components

Magnets appear in various auxiliary parts such as HVAC systems, safety devices, and driver assistance components, supporting smooth operation and reliability. By integrating magnets across these systems, EVs deliver the power, efficiency, and smart functionality drivers expect.

Why Choose NBAEM

Premium magnetic materials, tailored solutions, extensive experience, competitive pricing, and reliable delivery.

Quality Materials

ISO 9001 and TS 16949 certifications for automotive-grade quality. Rigorous testing ensures that every magnet meets strict performance and safety standards. Reliable supply chain with traceability for every batch.

Custom Solutions

Tailor-made magnets to fit your specific motor, sensor, or charging module designs Flexible solutions for brushless DC motors, regenerative braking, and wireless charging Rapid prototyping and fast turnaround times to meet tight project deadlines

Strong R&D Support

Collaborative development with customers focusing on future EV innovations Investment in research to improve magnet efficiency, heat resistance, and lightweight solutions Expertise in emerging areas like wireless charging magnets and advanced sensor magnets

Competitive Pricing

High-quality magnetic products at market-competitive prices for cost-effective solutions.

Extensive Experience

Leverage decades of expertise in magnetic materials to ensure innovative and reliable solutions.

Reliable Delivery

Timely and dependable delivery ensures your projects stay on schedule without compromise.

Case Studies & Success Stories

Optimizing Production Efficiency by 35%

NBAEM collaborated with a leading electric motor manufacturer to implement advanced magnetic materials, resulting in a 35% improvement in production throughput without compromising quality.

“NBAEM’s materials have transformed our manufacturing process. The efficiency gains exceeded our expectations.” - Sarah K., Operations Manager

Enhancing Motor Performance for Automotive Industry

Using NBAEM's high-quality samarium cobalt magnets, a prominent automotive provider increased motor torque output by 20%, enhancing vehicle performance and reducing energy consumption.

“NBAEM’s magnets significantly improved our motor efficiency and durability, a crucial factor for our electric vehicles.” - David L., Lead Engineer

Reducing Energy Losses in Electric Motors

NBAEM’s customized magnetic alloys helped a global supplier reduce energy losses in electric synchronous motors by 15%, translating into more sustainable and cost-effective solutions.

“The innovative magnetic materials from NBAEM are a game-changer for our sustainability goals.” - Emily S., Product Manager

Let’s Talk Magnetics

NBAEM is your trusted partner for precision magnetic materials and solutions. Whether you need custom magnets or engineering guidance, we’re here to help you find the perfect magnetic components for your application.

- Expert advice tailored to your industry needs

- Custom quotes and fast turnaround times

- Trusted by global manufacturers in automotive, electronics, and renewable energy

Frequently Asked Questions

Answers about magnet types, their performance, and certification from NBAEM.

Ferrite magnets, while less powerful, are widely used in automotive sensors for their stability and cost efficiency.