What Are NdFeB Magnets

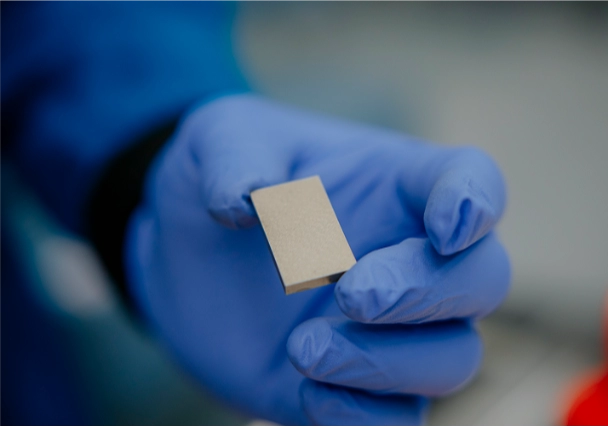

Neodymium-iron-boron (NdFeB) magnets are a type of rare earth magnet composed primarily of neodymium (Nd), iron (Fe), and boron (B). These magnets are known for their exceptional magnetic strength and resistance to demagnetization. The unique combination of these elements results in magnets with a high energy product, meaning they can produce stronger magnetic fields in a smaller volume compared to other magnet types.

Composition and Properties

- Neodymium (Nd): Provides strong magnetic capabilities.

- Iron (Fe): Adds structural stability and enhances magnetic performance.

- Boron (B): Improves magnetic anisotropy, helping magnets maintain their strength under challenging conditions.

Key properties of NdFeB magnets include:

- High maximum energy product (up to 52 MGOe)

- Strong coercivity (resistance to demagnetization)

- Excellent temperature stability (with grades available for high-temperature use)

Why NdFeB Magnets Are Preferred in High-Performance Applications

NdFeB magnets stand out for applications demanding strong, compact magnets with reliable performance. Their high magnetic strength allows for the design of smaller, lighter components without sacrificing power, which is critical in industries like electric vehicles, aerospace, and electronics.

Comparison with Other Magnet Types

| Magnet Type | Maximum Energy Product (MGOe) | Temperature Stability | Typical Applications |

|---|---|---|---|

| NdFeB | 35 – 52 | Moderate to high (graded) | EV motors, sensors, electronics |

| Samarium-Cobalt | 20 – 32 | Excellent (high-temp) | Aerospace, military |

| Ferrite (Ceramic) | 1 – 4.5 | Good | Loudspeakers, appliances |

| Alnico | 5 – 9 | Very high | Sensors, microphones |

Compared to ceramic and alnico magnets, NdFeB magnets provide much stronger magnetic fields, enabling higher power densities and smaller sizes. While samarium-cobalt magnets offer better temperature resistance, NdFeB magnets are more cost-effective and widely used, especially where moderate temperature stability is sufficient.

For more details on magnetic materials used in motor technology, visit magnetic materials in motor technology.

Application of NdFeB Magnets in New Energy Vehicles

NdFeB magnets play a crucial role in the heart of new energy vehicles (NEVs). They’re mainly used in electric motors, where their strong magnetic properties help boost efficiency and power density. This means motors can deliver more power without getting bigger or heavier—perfect for the demands of EVs that need to be both powerful and lightweight.

Beyond motors, these rare earth magnets are key in regenerative braking systems. They help convert the kinetic energy during braking back into electrical energy, increasing overall energy efficiency and extending the vehicle’s driving range.

NdFeB magnets also appear in various sensors and electronic components across the vehicle, supporting functions like position detection and speed monitoring. These components rely on precise magnetic performance for better control and safety.

Some leading EV manufacturers, including Tesla, GM, and Volkswagen, have widely adopted NdFeB magnets in their motor designs and other electronic systems. Their preference highlights how essential these magnets are in building high-performance, reliable new energy vehicles.

Advantages of NdFeB Magnets in EVs

NdFeB magnets offer some clear advantages that make them a top choice for electric vehicles in the U.S. market. First, their high magnetic strength significantly boosts motor efficiency. This means the motors can produce more power without using extra energy, which is a big win for performance.

Because of their powerful magnetic properties, NdFeB magnets allow for smaller, lighter motor designs. This size and weight reduction helps manufacturers create more compact vehicles that are easier to handle and improve overall vehicle dynamics.

The stronger magnets also contribute to an improved driving range and better energy efficiency. By requiring less power to generate the same output, EVs equipped with NdFeB magnets can travel farther on a single charge — a key factor for American drivers who want reliable, long-distance travel.

Lastly, these magnets provide reliability and operational stability. They perform consistently under different temperatures and driving conditions, ensuring that electric motors keep running smoothly without unexpected drops in performance.

In short, NdFeB magnets help EVs become more efficient, lighter, and more dependable — exactly what drivers in the U.S. want from their new energy vehicles.

Challenges and Solutions in the Use of NdFeB Magnets in NEVs

NdFeB magnets rely heavily on rare earth elements like neodymium, which face supply chain risks. These materials are mostly mined and processed in limited regions, making availability sensitive to geopolitical tensions and trade restrictions. For U.S. manufacturers and customers, this means potential price volatility and supply uncertainty.

Environmental concerns also come with rare earth mining and processing. These activities can cause pollution and generate hazardous waste, raising sustainability questions in the electric vehicle sector, where clean energy goals are top priority.

NBAEM and the broader industry are actively addressing these challenges by focusing on:

- Ethical sourcing: Ensuring rare earths come from responsible mines with transparent supply chains.

- Sustainability efforts: Investing in cleaner mining technologies and recycling rare earth materials to reduce environmental impact.

- Technological innovation: Developing new magnet formulas and production methods that reduce reliance on critical elements without sacrificing performance.

These moves help stabilize the supply of NdFeB magnets and support a more sustainable, reliable future for new energy vehicles in the U.S. market.

Market Trends and Future Outlook

The demand for NdFeB magnets is rising fast, largely because the new energy vehicle (NEV) market in the U.S. and worldwide keeps expanding. As more electric vehicles hit the roads, manufacturers need stronger, lighter, and more efficient magnets to boost motor performance and extend driving range. NdFeB magnets are at the core of this growth thanks to their unmatched magnetic strength.

Innovation in magnet technology is pushing NEV performance even further. Advances focus on improving thermal stability, reducing reliance on critical rare earth elements, and enhancing magnet durability. These improvements help make electric motors more efficient and reliable, which benefits both automakers and drivers.

NBAEM is well-positioned to meet these evolving market needs. With a strong focus on research and development, NBAEM offers advanced NdFeB magnetic materials tailored for the latest NEV applications. Their ability to customize products and ensure sustainable sourcing sets them apart as a trusted supplier in the electric vehicle industry.

Why Choose NBAEM for NdFeB Magnets

NBAEM stands out as a top NdFeB magnet supplier in China, delivering reliable solutions tailored for the U.S. new energy vehicle market. Here’s why they’re trusted by EV makers and manufacturers:

Expertise and Manufacturing Excellence

- Decades of experience in magnetic material manufacturing

- Advanced production processes ensuring consistent high-performance magnets

- Strong R&D team developing next-gen magnet tech for EVs

Quality Assurance and Customization

- Strict quality control standards to meet automotive industry requirements

- Flexible customization options to fit specific electric vehicle motor designs

- In-house testing facilities for magnetic strength, durability, and thermal stability

Commitment to Sustainability and Ethics

- Responsible sourcing of rare earth elements to reduce environmental impact

- Transparent supply chain management addressing geopolitical risks

- Partnerships with ethical mining operators supporting sustainable rare earth use

Proven Industry Partnerships and Client Success

- Collaborations with leading EV manufacturers in the U.S. and worldwide

- Case studies demonstrating improved motor efficiency and vehicle performance using NBAEM magnets

- Ongoing support and technical consultation for product integration and optimization

| NBAEM Strengths | Why It Matters for U.S. EV Market |

|---|---|

| High-quality NdFeB magnets | Boost motor efficiency and power density |

| Custom magnet solutions | Meet diverse electric motor and sensor needs |

| Sustainable supply chain | Ensure long-term material availability |

| Strong client support | Faster problem-solving and product upgrades |

Choosing NBAEM means reliable access to premium NdFeB magnets that help U.S. new energy vehicle manufacturers build efficient, lighter, and longer-range EVs—all with a focus on sustainability and quality.

Leave A Comment