Magnetic anisotropy means that a material has a preferred direction for its magnetic moments when you apply a magnetic field to it. In simpler terms, it means that the way a material is pointed affects how it behaves magnetically. Some materials want to be magnetized more in one direction than others. We call that the “easy” axis. They don’t want to be magnetized in other directions.

Causes of Magnetic Anisotropy

There are a couple of things that cause magnetic anisotropy.

- Crystal Structure: The symmetry of the crystal lattice of a material can create an easy axis. Cubic materials often want to point their magnetization along the body diagonal. Non-cubic materials want to point their magnetization along certain crystal axes. We call this magnetocrystalline anisotropy. This is the only intrinsic cause of anisotropy because it comes from the structure of the material.

- Shape Anisotropy: When you have non-spherical objects like thin films or small particles, you can get anisotropy because of surface or edge effects. The shape of the material affects how it responds to an external magnetic field. The demagnetizing fields are different depending on which way you measure them.

- Spin-Orbit Coupling: The interaction between the spin of the electrons and the motion of the electrons around the nucleus can make the magnetization want to point in a certain direction.

- Magnetoelastic Anisotropy: If you put a mechanical strain or tension on a material, you can change how it behaves magnetically.

- Exchange Anisotropy: This has to do with the interactions between the magnetic moments in the materials. When you have ferromagnetic and antiferromagnetic materials coupled together, the antiferromagnetic layer can affect the way the magnetization behaves in the ferromagnetic layer.

- Doping and Impurities: You can intentionally introduce impurities or defects into a material to change its electronic structure, which can affect how it behaves magnetically and its anisotropy

- Strain: When you mechanically deform a material, you distort the symmetry of its crystal structure. This distortion can change where the easy axis is and how it behaves magnetically.

Types of Magnetic Anisotropy

There are a few different types of magnetic anisotropy.

- Crystalline Anisotropy: This is when the crystal symmetry of the material determines where the easy axis is. You can see this in cubic and non-cubic materials.

- Shape Anisotropy: This is when the shape of the material determines where the easy axis is. You see this in thin films and nanoparticles.

- Magnetostriction: This is when the magnetism of the material interacts with the lattice structure, and the material expands or contracts when you apply a magnetic field to it.

- Magnetic Field Anisotropy: This is when the material has a high magnetic susceptibility, and the external magnetic field interacts with the magnetic moments in the material differently depending on which way the field is pointing.

Anisotropy in Hard and Soft Magnetic Materials

Hard Magnetic Materials: These materials, such as neodymium magnets, have high magnetic anisotropy, so they are resistant to demagnetization. We use their strong, directional magnetic properties in applications like motors and generators.

Soft Magnetic Materials: Less commonly, soft magnetic materials can also be anisotropic due to internal structural factors or external processing methods. Examples include grain-oriented electrical steels used in transformers.

Achieving Better Magnetic Anisotropy

Manufacturers can improve magnetic anisotropy by carefully controlling several factors during production:

Material Selection: The choice of base material, like neodymium in high-performance magnets, is key to getting strong magnetic properties.

Orientation and Processing Techniques: When we make the magnet, we line up the magnetic moments using processes like hot pressing or isostatic pressing. This helps us make magnets with better anisotropic properties.

Grain Size and Shape: We have good control over the grain size and shape of the material to make sure it has consistent magnetic properties.

Oxygen Content: We reduce the amount of oxygen during production to make the material flow better and keep the anisotropy.

Perpendicular Pressing Under a Magnetic Field: We line up the magnetic moments when we press the material during production. That’s how we get the anisotropy in the final product.

Anisotropic vs. Isotropic Magnets

Anisotropic Magnets: These magnets have magnetic properties that depend on the direction. For example, we make sintered neodymium magnets that have the grains lined up during manufacturing. This gives them strong magnetic performance in one preferred direction.

Isotropic Magnets: In contrast, isotropic magnets like bonded neodymium magnets don’t have a preferred direction for magnetization. They have similar magnetic properties in all directions. This allows you to shape and magnetize them in different orientations. They are generally weaker than anisotropic magnets.

Applications of Anisotropic Magnets

Anisotropic magnets have many uses in different industries because they have stronger magnetic strength and directionality. Here are a few examples:

- Sensors: We use anisotropic magnets, like samarium cobalt magnets, in sensors that change magnetic fields into electrical signals. You’ll find these sensors in automotive and aerospace systems.

- Generators: We use the magnetic field created by anisotropic magnets to make generators. For example, the magnets in wind turbines are anisotropic.

- Refrigeration: People are doing research to use magnets in refrigeration. For example, MIT is doing work on using magnets as a potential refrigerant.

- Nuclear Magnetic Resonance (NMR): We use anisotropic magnets to make NMR spectrometers. These machines let us study the physical and chemical properties of materials.

- Medical Applications: Anisotropic magnets are stable at high temperatures, so we use them in sterilizable medical devices and implants.

Knowing about magnetic anisotropy helps you use magnets to their best advantage in your specific application. Anisotropic magnets have a direction to them, which is a big deal. That’s why they’re used in so many different industries, from energy to healthcare. Isotropic magnets give you more flexibility in design but aren’t as strong. If you want to learn more about magnetic materials and how they can help you, get in touch with us at any time.

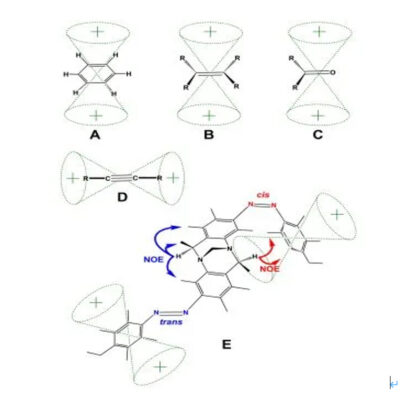

Magnetic Anisotropy. Image Source: Wikipedia

[…] Selecting the right magnetic material depends on motor type, operating conditions, and cost considerations. For a deeper understanding of magnetics basics, check out what is a magnetic moment and magnetic anisotropy. […]