Understanding Wave Energy Systems

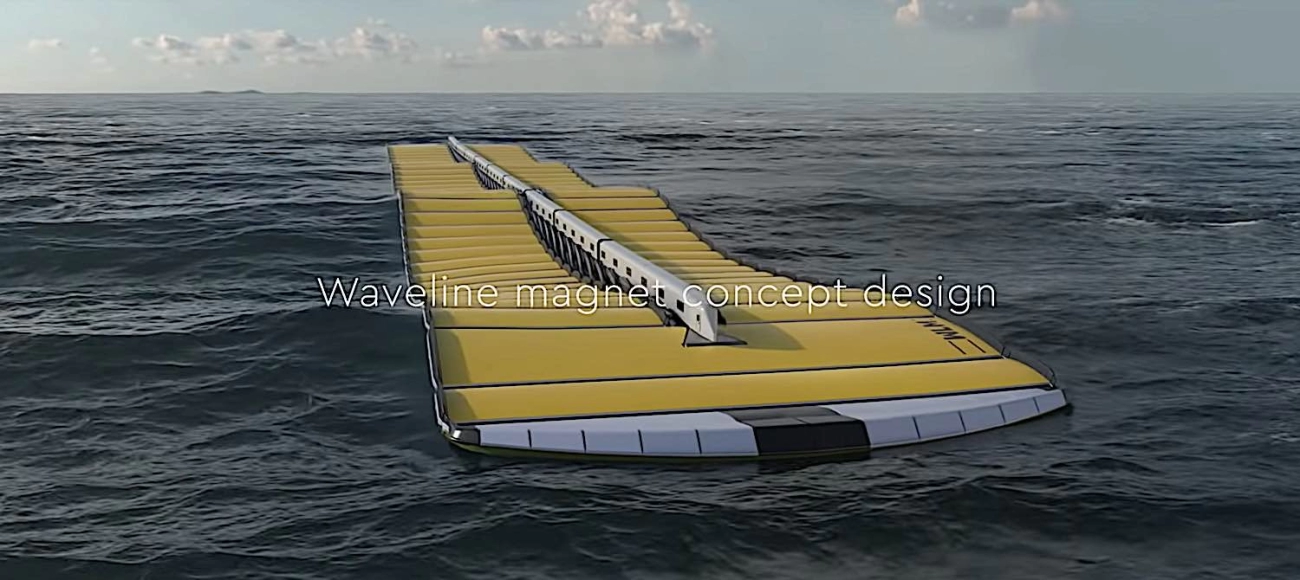

Wave energy systems capture the power generated by ocean waves to produce electricity. These systems use wave energy converters, which transform the kinetic and potential energy from waves into usable mechanical or electrical energy. Typically installed offshore or along coastlines, wave energy converters rely on reliable components like wave energy converter magnets and magnetic generators for wave energy to ensure efficient operation.

The process starts with the movement of waves that drives mechanical parts, often connected to power take-off systems. These systems use magnetic technology in wave energy harvesting to convert mechanical motion into electrical power. Key to this conversion are magnetic materials for renewable energy, such as neodymium magnets in marine applications, which offer high performance and durability under harsh sea conditions.

Understanding how wave energy systems work is essential for optimizing their design and improving energy output. Right magnetic solutions can enhance efficiency, reduce wear, and prolong the lifespan of wave power generators, making them more sustainable and cost-effective.

The Role of Magnetics in Wave Energy Systems

Magnetics play a crucial role in wave energy systems by converting the motion of ocean waves into usable electrical power. Key components like wave energy converter magnets and magnetic generators rely on strong, durable magnets—often neodymium magnets—to efficiently capture energy from wave movement. These magnets work within power take-off systems to transform mechanical energy into electricity with minimal losses.

Using corrosion-resistant magnetic materials is especially important in marine environments where saltwater exposure can degrade performance. High-performance magnets ensure long-lasting operation and maintain energy output, even under harsh conditions. Magnetic technology in wave energy harvesting enables reliable and efficient power generation, making it a vital element for renewable ocean energy projects.

For more on magnetic generators, check out NBAEM’s overview for magnetic generator.

Magnetic Solutions from NBAEM for Wave Energy Applications

NBAEM offers a range of magnetic solutions designed specifically for wave energy systems, focusing on reliability and performance in marine environments. Their high-performance neodymium magnets and durable magnetic materials are built to withstand harsh ocean conditions, including saltwater corrosion and constant mechanical stress. These magnets are ideal for use in wave energy converter magnets and magnetic generators for wave energy, helping to improve efficiency and power output.

Key features of NBAEM’s magnetic solutions include:

- Corrosion-resistant magnetic materials that extend the lifespan of wave power generators

- Strong magnetic flux density for efficient energy conversion in power take-off systems

- Customizable magnet shapes and sizes to fit different wave energy converter designs

- Sustainable magnetic materials sourced from reputable suppliers in China

By utilizing NBAEM’s expertise and advanced magnetic technology, wave energy projects in the U.S. can benefit from cutting-edge components that boost system durability and overall effectiveness. For those interested in magnet performance and design, NBAEM’s next-generation magnetic material design research offers additional insights into how these magnets are optimized for renewable energy applications.

This focus on durable, high-quality magnets makes NBAEM a practical choice for developers aiming to harness ocean energy reliably and sustainably.

Benefits of Using Magnetic Technologies in Wave Energy Systems

Magnetic technologies bring several advantages to wave energy systems, making them a preferred choice for power take-off and energy conversion applications. Here’s how magnetic solutions improve wave energy systems:

-

High Efficiency

Neodymium magnets in marine applications offer strong magnetic fields, enhancing the efficiency of wave energy converters. This means more power is harvested from waves with less energy loss.

-

Durability and Corrosion Resistance

Durable magnets for wave power generators are designed to withstand harsh marine environments. Using corrosion-resistant magnetic materials ensures long-lasting performance, reducing maintenance costs and downtime.

-

Compact and Lightweight Design

Magnetic generators for wave energy can be built compactly without sacrificing power output. This lightweight nature helps in easier installation and transportation of wave energy devices.

-

Improved Reliability

Magnetic solutions eliminate many mechanical parts prone to wear and tear, increasing system reliability. This makes wave energy harvesting more consistent, especially in rough ocean conditions.

-

Sustainable and Cost-Effective

Using sustainable magnetic materials sourced responsibly supports the growing demand for green energy. Magnetic systems often require less material and energy to manufacture, which lowers the overall environmental footprint.

| Benefit | Explanation | Impact |

|---|---|---|

| High Efficiency | Strong magnetic fields boost output | More energy from fewer waves |

| Durability | Corrosion-resistant coatings | Longer life, less maintenance |

| Compact Design | Lightweight and smaller components | Easier handling and installation |

| Increased Reliability | Fewer moving parts reduce failure risk | Continuous operation in tough settings |

| Sustainability | Eco-friendly magnetic materials | Supports green energy goals |

For more on magnetic materials and their types, see Type of Magnetic Materials.

Technological Innovations and Trends in Magnetic Materials for Wave Energy

The wave energy sector is evolving fast, and so are the magnetic materials used in these systems. Today’s innovations focus on boosting performance while ensuring durability in harsh marine environments. High-performance magnets, like neodymium magnets in marine applications, are getting stronger and more corrosion-resistant. This helps wave power generators last longer and be more efficient.

Manufacturers are also developing sustainable magnetic materials to meet environmental standards, especially important for the US market where green energy solutions are a priority. Magnetic solutions for power take-off systems are improving with better designs that reduce energy loss and enhance conversion rates.

Another trend is integrating smarter magnetic generators for wave energy, making maintenance easier and reducing downtime. Advances in coating technologies and alloys are providing better protection against saltwater corrosion, a key challenge in ocean energy. We’re also seeing a shift toward customized magnets tailored specifically for wave energy converters, optimizing the system’s overall efficiency.

These innovations ensure magnetic materials keep pace with the growing demand for reliable, long-lasting wave energy systems in the US and beyond.

Challenges and Considerations

When working with magnetic solutions for wave energy systems, there are a few key challenges to keep in mind. First off, corrosion resistance is a big deal. Since wave energy converters operate in harsh marine environments, magnets and magnetic materials must withstand saltwater and constant moisture without losing strength or breaking down.

Another challenge is durability. Wave power generators face constant movement and impact, so magnets need to be tough enough to handle that stress. Using durable magnets for wave power generators, like neodymium magnets with protective coatings, helps maintain long-term performance.

Cost is also important. High-performance magnets can get pricey, so balancing magnetic materials for renewable energy that provide strong output without overspending is crucial—especially for U.S. projects aiming for cost-effectiveness.

Finally, system integration can be tricky. Magnetic solutions have to fit precisely with power take-off systems and other mechanical parts. That means working closely with suppliers who understand the unique needs of wave energy equipment, including options from a sustainable magnetic materials supplier in China or local vendors, is essential.

To sum up, plan for corrosion protection, durability, cost, and proper integration when choosing magnetic solutions for wave energy. Addressing these challenges early helps keep your project efficient and reliable.

How to Choose the Right Magnetic Solutions for Your Wave Energy Project

Choosing the right magnetic solutions for your wave energy system is key to maximizing efficiency and durability. Here’s what to consider:

1. Understand Your System’s Needs

- Power Output Requirements: Match magnets to the energy target of your wave energy converter magnets.

- Operating Environment: Look for corrosion-resistant magnetic materials if the project is coastal or offshore.

- Durability: Use durable magnets for wave power generators to handle constant water movement and harsh marine conditions.

2. Select the Appropriate Magnet Type

- Neodymium Magnets in Marine Applications: Best for high-performance magnetic generators for wave energy due to their strength and size efficiency.

- Soft vs Hard Magnets: Hard magnets provide permanent magnetism; soft magnets are great for magnetic flux control. Check out soft magnetic materials vs hard magnetic materials for details.

3. Consider Technological Compatibility

- Ensure magnet size and shape fit your power take-off systems and magnetic generators.

- Check if the magnetic technology improves wave energy harvesting efficiency.

4. Quality and Supplier Reliability

- Source magnets from a trusted supplier for sustainable magnetic materials. Look for certifications and marine-grade magnetic materials.

- Consider working with suppliers experienced in the US market for better support and faster delivery.

Quick Comparison Table for Wave Energy Magnets

| Factor | What to Look For | Example |

|---|---|---|

| Magnet Type | High-performance, corrosion-resistant | Neodymium magnets in marine applications |

| Durability | Long-lasting under wet, salty conditions | Durable magnets for wave power generators |

| Size & Shape | Compatible with your system’s design | Customized magnetic solutions for PTO systems |

| Supplier Reliability | Proven track record, USA access | Sustainable magnetic materials supplier China |

With these points in mind, you’ll pick magnetic solutions that boost your wave energy project’s reliability and output. For more insights on magnetic materials research, check recent advances in magnetic material research.

Leave A Comment