Magnetization and demagnetization

Magnetization meaning:In classical electromagnetism,magnetization is the vector field that expresses the density of permanent or induced magnetic dipole moments in a magnetic material.

Demagnetization meaning:to lose magnetic properties or remove magnetic properties.

Magnetization and demagnetization are two processes that go together. If you want to understand how ferromagnetic materials such as iron, steel, or special magnetic alloys work, you need to understand these two processes. If you want to know how to select the right demagnetizer to make sure your workpieces are free of magnetism, which affects your product quality and production efficiency, you need to understand these two processes.

Magnetizing and Demagnetizing Magnetic Materials

In ferromagnetic materials, when you put an external magnetic field (H field) on them, they become magnetized. What’s happening is all the microscopic regions inside the material, called domains, are aligning with that field. Each domain is a little magnet, and the domains are separated by domain walls. When you first put a magnetic field on a piece of iron or steel or any ferromagnetic material, the domains are randomly oriented. As you put an external magnetic field on the material, the domain walls move, and you get bigger domains, which means you have more magnetic flux (B field) inside the material. The process of aligning the domains is not smooth. It happens in steps, which are called Barkhausen jumps. As you get close to magnetic saturation, you might have one big domain where all the little magnets are aligned with the external magnetic field.

Ferromagnetic materials also retain some magnetism after you take the external field away. We call this remanence or residual magnetism. To remove that residual magnetism, you need to demagnetize it. Demagnetizing is done by putting an alternating magnetic field on it. That alternating field disrupts the uniform alignment of the domains and returns them to a disordered state. How well you demagnetize something depends on the strength of the field you put on it, the coil configuration, and the frequency of the alternating field. The frequency is important because it homogenizes the domains and progressively demagnetizes the component from the inside out.

Methods for Demagnetizing

There are several ways to demagnetize a ferromagnetic material:

- Heat it above its Curie temperature, and it loses its magnetic properties forever.

- Vibrate or impact it. When you do this, you disturb the alignment of the domains ever so slightly, which causes a slight demagnetization effect.

- Put an alternating magnetic field on it, which decreases in strength slowly, which randomizes the alignment of the domains.

- Reverse the polarity of the magnetic field with a knockdown demagnetization process. You can measure the field setting and make the magnetism go almost to zero.

Demagnetizing Permanent Magnets

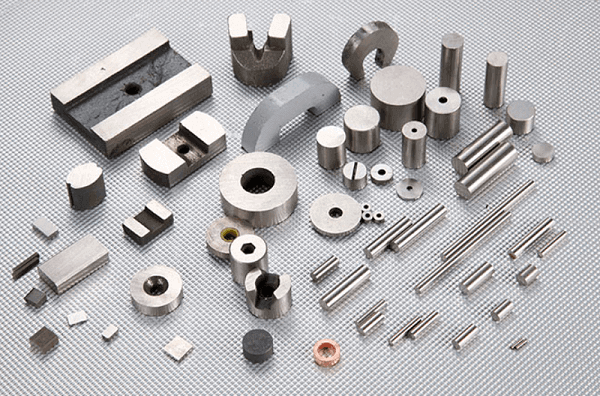

Permanent magnets are made from neodymium-iron-boron, samarium-cobalt, or alnico alloys. These are designed to have their magnetic properties forever under normal operating conditions. However, they can become demagnetized under certain conditions. Something can happen to them that causes them to lose their magnetism. For example, if you heat them up too much, if you hit them, or if you put them in a magnetic field that goes against their magnetism, they can become demagnetized.

- Heat is the primary thing that demagnetizes magnets. As you heat something up, the atoms move around and disrupt the alignment of the domains. When you get the magnet up to its Curie temperature, it loses its magnetism completely. The Curie temperature is different for different types of magnetic materials. For example, neodymium magnets have a low Curie temperature, and if you get them up to around 100°C, they can demagnetize. Samarium-cobalt magnets can go up to 350°C before they start to demagnetize, and alnico magnets can go up to 540°C before they start to demagnetize.

- Mechanical impacts can also demagnetize magnets. When you hit a magnet or if it gets hit, it disturbs the atomic structure, and it can cause the magnet to lose some or all of its magnetism. Also, magnets can erode or lose volume due to physical processes like oxidation. As that happens, the magnetism goes away.

- Conflicting magnetic fields can demagnetize magnets. When you put a magnet in a magnetic field that goes against its magnetism, it can lose its magnetism. If you put a magnet in a magnetic field that goes against the magnetism, the magnetic field inside the magnet is disrupted, and it can lose its magnetism. Storing magnets correctly is important to keep the magnetism and keep them away from other magnetic fields or from things that can damage them.

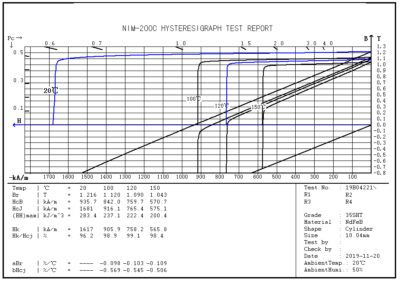

Understanding the Demagnetization Curve

The demagnetization curve is a valuable tool for evaluating a magnet. It shows the relationship between the magnetic flux density (B) and the magnetizing field strength (H). The demagnetization curve helps you understand how a magnet will perform under different conditions. The demagnetization curve can also help you determine the permeance coefficient, which tells you how a magnet will demagnetize at different temperatures or under different loads.

.

Restoring Magnetism

In some cases, you can restore a magnet’s magnetism. This process is called re-magnetization. You can take a magnet and put it in a solenoid coil. You can apply an electric current to the coil. That electric current may cause the domains to realign and restore the magnetic field. Whether or not you can do this depends on how much the magnet has been demagnetized and what happened to it to make it lose its magnetism.

Conclusion

Knowing how to magnetize and demagnetize is key to getting the best performance from ferromagnetic materials and permanent magnets in your applications. By controlling the environment, such as the temperature and the magnetic fields around it, and by choosing the right demagnetization methods, you can make sure your magnetic components will work the way you want them to. If you need help, talk to an expert. They can help you find the best way to do what you need to do with your magnets and magnetic assemblies.

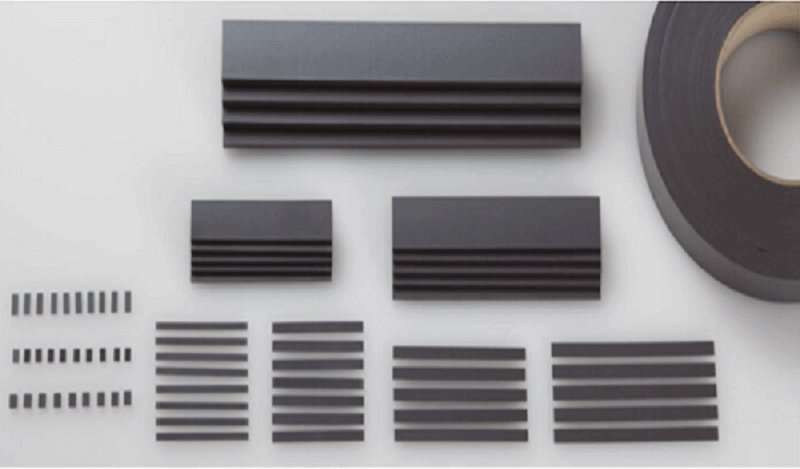

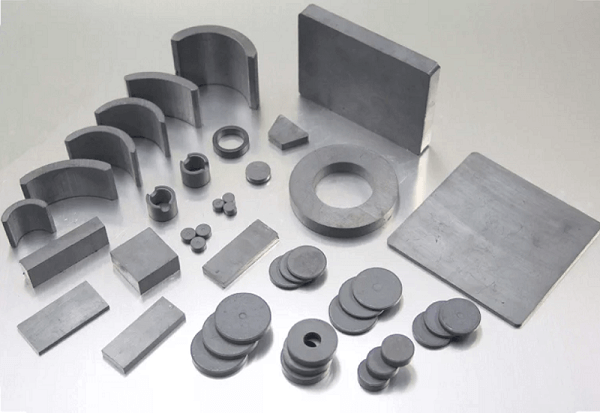

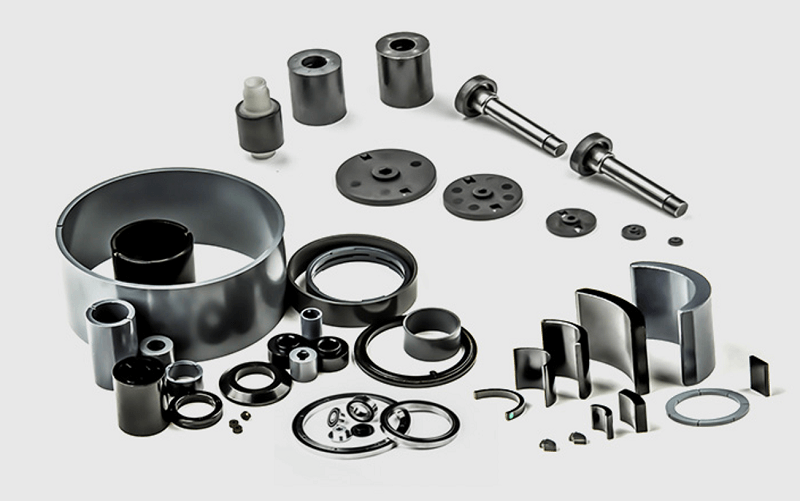

NBAEM, is the professional magnetic materials supplier from China. We have exported bespoke magnetic materials for more than ten years. We provide quality products and high-standard service. If you are looking for any magnetic materials sourcing or if you have any questions during importing the magnetic products from China, you can contact us directly.

[…] wastes money, while under-specifying leads to product returns. Understanding the physics behind magnetization and demagnetization helps in selecting a grade that maintains a consistent closure over the lifespan of the packaging. […]