Permanent Magnets Required for Off-Grid Small Wind Turbines

Off-grid small wind turbines are mainly used for electricity supply in remote areas, homes, and small industrial facilities. As one of the core components of the generator, the choice of permanent magnets is crucial. This article will describe the required permanent magnets for off-grid small wind turbines in terms of shape, material, coating, and performance.

Shape

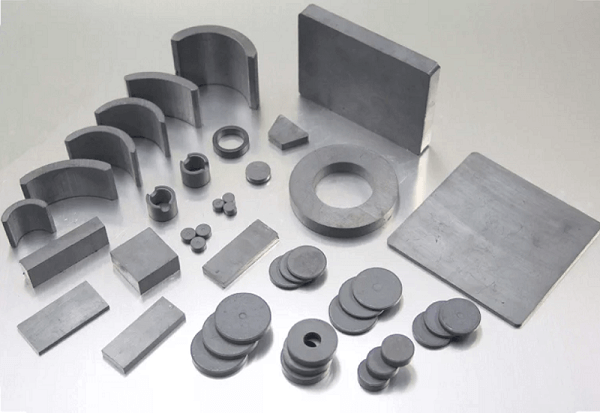

The shape of the permanent magnet directly affects the efficiency and stability of the wind turbine. Common shapes include:

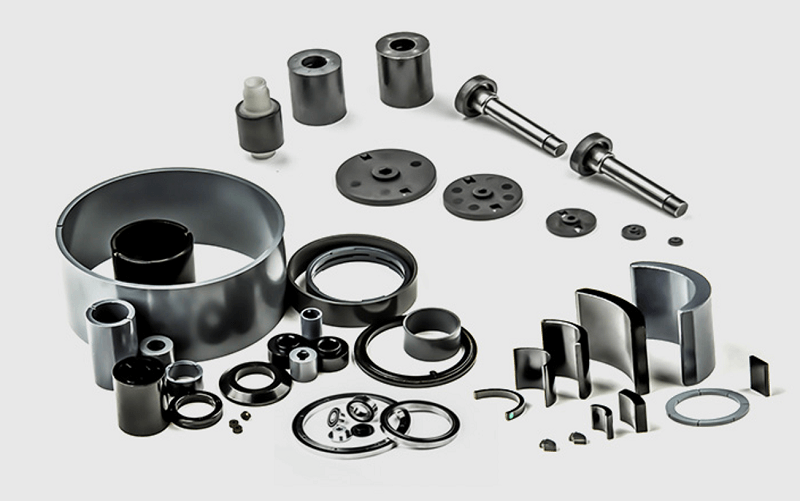

- Block Magnets: Most common, easy to manufacture and install, suitable for most small wind turbines.

- Cylindrical Magnets: Suitable for specifically designed generators, beneficial for uniform magnetic field distribution.

- Arc-Shaped Magnets: Often used in the stator or rotor parts, capable of providing a more uniform magnetic field, improving power generation efficiency.

Material

The material of the permanent magnet determines its magnetic performance, durability, and cost. Common permanent magnet materials include:

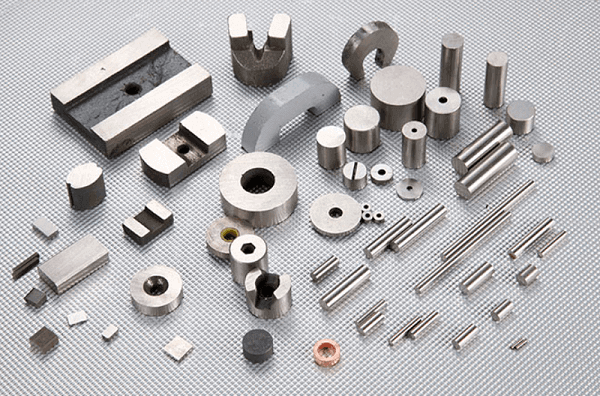

- Neodymium Iron Boron (NdFeB): The strongest permanent magnet material with high energy product and excellent performance. Suitable for high-performance wind turbines. However, it is expensive and sensitive to environmental temperatures, requiring attention to operating temperature range.

- Samarium Cobalt (SmCo): Excellent temperature stability and corrosion resistance, but the energy product is slightly lower than NdFeB, and the cost is high. Suitable for small wind turbines in extreme environments.

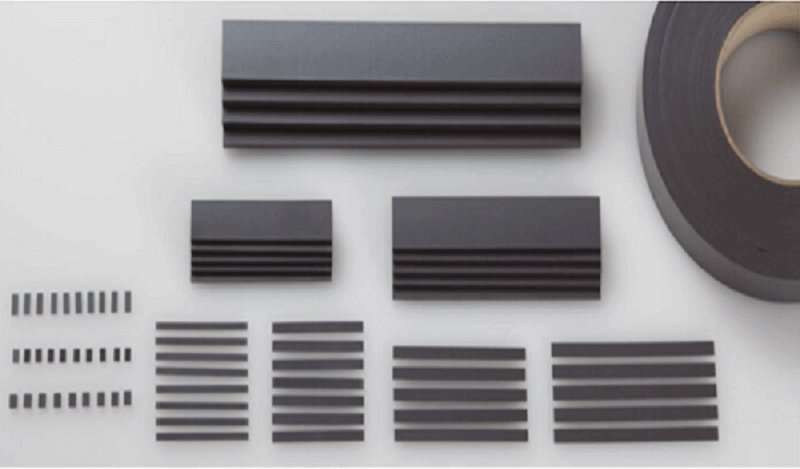

- Ferrite: Low cost, corrosion-resistant, suitable for economical small wind turbines with low performance requirements. However, its energy product and magnetic properties are far inferior to the first two.

Coating

The surface treatment of permanent magnets significantly affects their lifespan and performance. Common coatings include:

- Nickel (Ni) Plating: Provides good corrosion resistance and mechanical protection, the most common coating for NdFeB magnets.

- Zinc (Zn) Plating: Lower cost, provides basic protective effect, suitable for low-cost applications.

- Epoxy Coating: Offers excellent corrosion resistance and electrical insulation, suitable for high humidity environments.

- Gold Plating: Provides the best corrosion protection but is expensive, used for special applications.

Performance

The performance indicators of permanent magnets include energy product, coercivity, and remanence, directly affecting the efficiency and stability of the generator.

- Energy Product (BHmax): Indicates the ability of the magnet to store energy. NdFeB magnets have the highest energy product, up to 50 MGOe or more, suitable for efficient generators.

- Coercivity (Hc): Indicates the magnet’s ability to resist demagnetization. High coercivity ensures that the magnet does not demagnetize under high temperatures and strong magnetic fields.

- Remanence (Br): Indicates the magnetic flux density of the magnet. High remanence helps to increase the output voltage and power of the generator.

.

Summary

Off-grid small wind turbines have strict requirements for permanent magnets, needing to consider shape, material, coating, and performance comprehensively. NdFeB magnets, due to their high performance, are the preferred material but require attention to environmental temperature and corrosion prevention. SmCo magnets are suitable for high-temperature and harsh environments, while ferrite magnets are suitable for economical applications. Choosing the right permanent magnet can significantly improve the efficiency and lifespan of wind turbines, providing stable power supply for off-grid users.

NBAEM, is the professional magnetic materials supplier from China. We have exported bespoke magnetic materials for more than ten years. We provide quality products and high-standard service. If you are looking for any magnetic materials sourcing or if you have any questions during importing the magnetic products from China, you can contact us directly.

Leave A Comment