Understanding NdFeB Magnet Grades

Magnet grades

NdFeB magnet grades tell you how strong a magnet is, how well it resists demagnetization, and how much heat it can handle. These grades make it easier to pick the right magnet for your needs, whether it’s for a consumer device or industrial use.

The naming system usually looks like this: N35, N52, N38SH, and so on. The “N” stands for neodymium, and the number that follows (like 35 or 52) refers to the magnet’s maximum energy product, or BHmax, measured in Mega-Gauss Oersteds (MGOe). This value shows the magnetic strength—the higher the number, the stronger the magnet.

Sometimes you’ll see letters attached, such as SH, UH, EH, AH, or VH. These letters indicate the magnet’s temperature resistance range:

- SH: Safe up to about 180°C

- UH: Safe up to about 200°C

- EH: Safe up to about 220°C

- AH: Safe up to about 230°C

- VH: Safe up to about 240°C

Key parameters in NdFeB magnet grades include:

- BHmax (Maximum Energy Product): The overall magnetic strength.

- Intrinsic Coercivity (Hci): The magnet’s ability to resist demagnetization. Higher Hci means better resistance.

- Remanence (Br): The magnet’s magnetic flux density or how strong the magnetic field remains after magnetization.

- Maximum Operating Temperature: The highest temperature at which the magnet can work without losing its magnetic properties.

Understanding these values helps you choose the best magnet grade for your application, whether you prioritize strength, heat resistance, or lasting performance.

Common NdFeB Magnet Grades and Their Characteristics

Soft magnet Grades N33 N35 N38

These are your budget-friendly, general-purpose magnets. They offer decent magnetic strength and work well for everyday applications where extreme power or temperature resistance isn’t critical.

- Pros: Affordable, easy to source, good enough for basic uses like simple motors or sensors.

- Cons: Lower magnetic strength compared to higher grades, less temperature stability.

Medium magnet Grades N40 N42 N45

These grades strike a balance between price and performance, making them popular for many industrial uses. They have better magnetic strength and slightly improved temperature stability than soft grades.

- Ideal for electric motors, small generators, and industrial tools that need consistent reliability without breaking the bank.

High magnet Grades N48 N50 N52

When you need top-tier magnetic power, these high grades are the go-to. They deliver strong magnetic flux and high energy density, perfect for high-performance applications.

- Used in advanced motor designs, robotics, medical devices, and where space or weight is limited but power can’t be compromised.

- Typically more expensive but offer maximum strength for challenging projects.

Heat Resistant magnet Grades SH UH EH AH VH

Designed for tough environments, these grades maintain their magnetic properties at elevated temperatures. Each letter indicates increasing heat resistance:

- SH: Stable up to about 180°C

- UH: Up to 200°C

- EH: Up to 220°C

- AH: Up to 230°C

- VH: Up to 240°C or higher

These are essential for automotive systems, aerospace, or industrial equipment exposed to constant heat.

Rare and Custom magnet Grades

For unique projects that don’t fit standard specs, custom NdFeB magnets come in. These might have special coatings, tailored shapes, or adjusted compositions to meet specific demands—like unusual temperature ranges, corrosion resistance, or precise shapes.

- Often used in cutting-edge tech, renewable energy, or specialized manufacturing.

- Custom orders might take longer but ensure the magnet fits perfectly in specialized U.S. industries.

Performance Comparison of Various magnet Grades

Understanding how different NdFeB magnet grades stack up requires looking at key parameters like BHmax (maximum energy product), Hci (intrinsic coercivity), Br (remanence), and maximum operating temperature. These factors directly affect how a magnet performs in everyday applications, determining its strength, resistance to demagnetization, and ability to work under heat.

Here’s a simple comparison table to visualize these differences:

| Grade | BHmax (MGOe) | Hci (kOe) | Br (kG) | Max Operating Temp (°C) | Application Focus |

|---|---|---|---|---|---|

| N33 | 33 | 11 | 12.2 | 80 | General purpose, budget-friendly |

| N38 | 38 | 12 | 12.6 | 80 | Everyday industrial use |

| N42 | 42 | 12 | 13.2 | 80 | Balanced strength and reliability |

| N48 | 48 | 12 | 13.6 | 80 | High-strength industrial |

| N52 | 52 | 12 | 14.1 | 80 | Maximum magnetic strength |

| N38SH | 38 | 18 | 12.6 | 150 | Heat resistance, mid-strength |

| N40UH | 40 | 22 | 13.2 | 180 | High-temp industrial |

| N35EH | 35 | 25 | 12.0 | 200 | Increased heat tolerance |

How These Parameters Affect Performance

-

BHmax (Magnetic Strength)

Higher BHmax means stronger magnets. For example, N52 offers the highest magnetic force but may not be the best in high heat.

-

Hci (Coercivity)

This is a magnet’s ability to resist becoming demagnetized. Higher coercivity values (like in SH, UH, EH grades) mean the magnet holds its strength better in tough conditions.

-

Br (Remanence)

Indicates the magnet’s residual magnetism. This impacts the overall magnetic field strength available for use.

-

Maximum Operating Temperature

Critical for applications in motors, automotive, or renewable energy where magnets face heat. Standard grades max out around 80°C, while SH, UH, and EH grades can withstand 150-200°C or more.

Choosing the right grade depends on balancing these factors based on the specific needs—whether it’s just strong magnetic pull, resistance to heat, or longevity under tough environments.

For more detailed guidance on picking the best grade, check out our article on which is better N42 or N52 magnets.

Applications for Different NdFeB Magnet Grades

NdFeB magnets are everywhere, and different grades fit different needs. Here’s how various industries use specific grades to get the best performance:

| Application | Magnet Grades Used | Why These magnet Grades Work |

|---|---|---|

| Consumer Electronics | N33, N35, N38 | Affordable, good magnetic strength, suitable for small devices like speakers, headphones, and sensors |

| Motors and Generators | N40, N42, N45 | Balanced power and durability for electric motors and generators in industrial and home setups |

| Magnetic Resonance Imaging (MRI) | High Grades N48, N50, N52 | High magnetic strength for precise imaging quality and stable magnetic fields |

| Automotive Systems & Hybrid Electric Vehicles | Heat Resistant Grades SH, UH | Withstand higher operating temperatures, critical for EV motors and sensors |

| Renewable Energy Wind Turbines | High and Heat Resistant Grades EH, AH, VH | Handle high temperatures and strong magnetic forces in harsh outdoor environments |

| Industrial Equipment | Medium to High Grades N40 to N52 | Durable magnets with reliable magnetic strength for tools, machines, and automation |

Choosing the right NdFeB magnet grade ensures your product or system runs efficiently and lasts longer in its specific environment.

Factors to Consider When Choosing an NdFeB Magnet Grades

Picking the right NdFeB magnet grade depends on several key factors that impact your project’s success and cost-effectiveness.

Required Magnetic Strength

Start with how strong the magnet needs to be for your application. Higher grades like N50 or N52 offer stronger magnetic force but often come at a higher cost. For less demanding uses, medium or soft grades may be sufficient and more economical.

Operating Temperature Range

NdFeB magnets lose strength when exposed to heat. If your project involves high temperatures, you’ll want to choose heat resistant grades such as SH, UH, or VH. These are designed to maintain magnetic performance in tough thermal environments without demagnetizing.

Mechanical and Environmental Conditions

Consider exposure to moisture, vibration, or shocks. NdFeB magnets are brittle, so protective coatings or mechanical housing might be required. The operating environment influences which grade and finishing touch are the best fit.

Cost Considerations

Stronger, heat-resistant, or custom magnets come at a premium. Balancing performance requirements with your budget is crucial. Often, medium grades provide a sweet spot of strength and cost-efficiency for industrial uses.

Availability and Supply Chain

Reliable supply is critical to avoid production delays. NBAEM is a trusted supplier with stable inventory and manufacturing capacity, helping ensure you get the right magnets when you need them. Their consistent quality control and customization options make sourcing hassle-free.

By weighing these factors, you can select an NdFeB magnet grade that fits your technical needs and business goals. For detailed specs or guidance on magnet strength, check out NBAEM’s resources on how to measure magnet strength and their grade chart to find the best match.

Quality Control and Industry Standards

NdFeB magnet grades must meet strict international standards to ensure safety, performance, and environmental compliance. Common standards like ISO guarantee consistent quality through well-defined manufacturing processes. At the same time, RoHS and REACH certifications confirm that magnets are free from hazardous substances, making them safe for end users and environmentally friendly.

At NBAEM, quality control is a top priority. Each batch of magnets undergoes thorough testing, including:

- Magnetic strength verification (BHmax, Br)

- Intrinsic coercivity (Hci) checks

- Temperature resistance testing up to specified grade limits

- Physical inspections for defects or inconsistencies

This rigorous certification process ensures the magnets perform reliably in your applications, whether for industrial uses, electronics, or automotive systems. NBAEM’s commitment to meeting these industry standards reflects their focus on providing high-quality, compliant NdFeB magnet grades tailored for U.S. customers.

Why Choose NBAEM for Your NdFeB Magnet Supply

When it comes to sourcing high-quality NdFeB magnets, NBAEM stands out as a reliable supplier catering to the U.S. market’s needs.

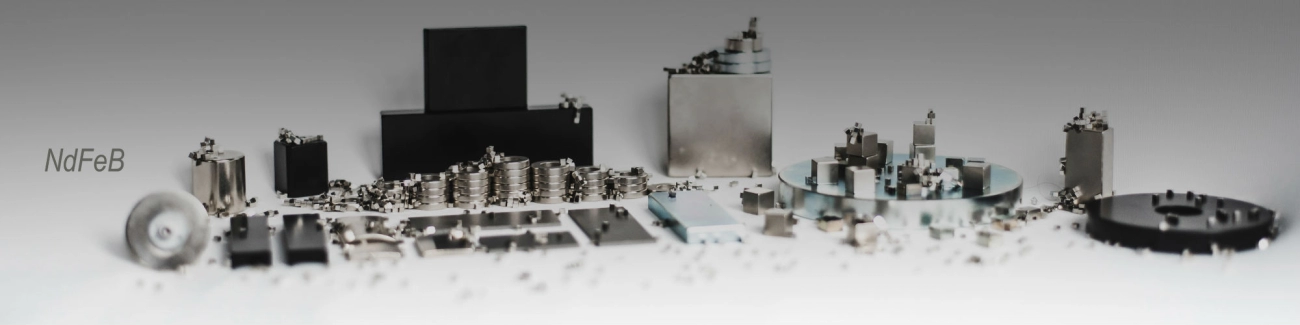

Manufacturing Capabilities

- Advanced production lines with precise control over magnet composition and dimensions

- Ability to produce a wide range of NdFeB magnet grades from soft to heat resistant types

- Custom manufacturing that fits unique industrial specifications

Quality Assurance

- Strict testing procedures to ensure magnets meet international standards like ISO, RoHS, and REACH

- Consistent magnetic performance and durability guaranteed

- Regular quality checks at every manufacturing stage

Customization and Pricing

- Tailored magnet solutions based on your application requirements

- Competitive pricing without compromising on material or magnetic strength

- Flexible order sizes, from prototypes to large-volume production runs

Technical Support and Bulk Orders

- Expert consultation available to help select the optimal NdFeB magnet grade

- Guidance on magnet integration and performance optimization

- Efficient handling of bulk orders with timely delivery

Partnering with NBAEM means reliable supply, quality products, and professional support—all crucial for your NdFeB magnet needs. For more on our manufacturing range and magnet types, check out our high temperature magnets page or explore the main magnetic properties of these powerful magnets.

Leave A Comment