Understanding NdFeB Magnets

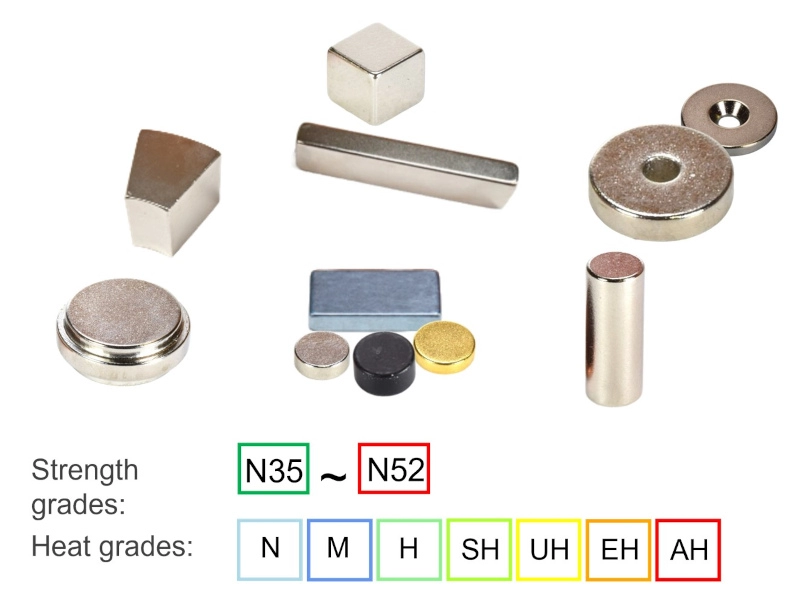

NdFeB magnets, also known as neodymium magnets, are made from an alloy of neodymium, iron, and boron. This unique composition gives them exceptional magnetic properties that outperform many traditional magnets. Compared to ferrite, Alnico, and samarium cobalt (SmCo) magnets, NdFeB magnets offer the highest magnetic strength, making them ideal for applications where a powerful, compact magnet is needed.

In terms of performance, NdFeB magnets deliver a strong magnetic field with excellent energy density. This means they can produce superior magnetic force even in smaller sizes. Ferrite magnets, while cost-effective, have lower magnetic strength, and Alnico magnets typically offer less resistance to demagnetization. SmCo magnets are durable but usually come at a higher cost and have lower maximum energy product than NdFeB magnets.

NdFeB magnets also stand out for their durability and operational temperature range. While their optimal performance is in environments below 176°F (80°C), newer grades tolerate temperatures up to 320°F (160°C), making them suitable for many industrial uses. Proper coatings and treatments further enhance their resistance to corrosion and mechanical wear, ensuring longevity in demanding settings. This combination of strength, compact size, and durability makes NdFeB magnets the top choice for magnetic separation technology.

What is a Magnetic Separator

A magnetic separator is a device that removes magnetic materials from a mixture using a magnetic field. It works by attracting and capturing ferrous particles, separating them from non-magnetic materials. This process helps protect machinery, improve product quality, and recover valuable metals.

There are several types of magnetic separators, including:

- Dry Magnetic Separators: Used for dry materials like powders and granules, often in industries like mining and food processing.

- Wet Magnetic Separators: Designed for slurry or liquid mixtures, common in mineral processing.

- Overband Magnets: Installed above conveyors to catch tramp metal without stopping production.

- Drum Magnets: Rotate to continuously separate magnetic particles from bulk materials on conveyors.

Magnetic separators are widely used in industries such as mining, recycling, food production, pharmaceuticals, and manufacturing. They help remove contaminants, recover metals, and ensure smooth operations in processing lines. Using NdFeB magnets in these separators enhances their ability to capture smaller and weaker magnetic particles efficiently.

Why Are NdFeB Magnets Used in Magnetic Separators

NdFeB magnets are the go-to choice for magnetic separators because they pack a powerful magnetic punch while staying compact. This strong magnetic force means they can pull out smaller and weaker magnetic particles more effectively, boosting separation efficiency and allowing for higher throughput in processing.

These magnets also save energy; their strong magnetic field requires less power to operate the separator compared to other magnet types. Plus, they tend to last longer, maintaining their strength without frequent replacements. NdFeB magnets resist demagnetization during tough industrial conditions, which keeps your separator running reliably over time.

Another key advantage is their versatility. Whether you’re handling fine powders or larger chunks, dry or wet materials, NdFeB magnets adapt well, making them suitable for a wide range of industries and separation needs.

Key Applications of NdFeB Magnets in Magnetic Separation

NdFeB magnets are widely used in magnetic separators across many industries due to their strong magnetic power and reliability. Here’s where they make a real impact:

-

Mining and Mineral Processing

NdFeB magnets efficiently separate valuable ores from waste material, improving extraction rates and reducing processing time.

-

Recycling and Waste Management

These magnets help remove metal contaminants from recycled plastics, glass, and other materials, ensuring cleaner end products and protecting machinery.

-

Food and Pharmaceutical Industries

NdFeB magnets are used to catch tiny metal fragments in food and medicine manufacturing, supporting strict safety and quality standards.

-

Chemical and Metallurgical Processes

They aid in separating metals and impurities during production, enhancing product purity and process efficiency.

-

Electronics and Automotive Sectors

NdFeB magnets remove metal debris that could damage electronics or automotive parts, helping maintain product integrity and reliability.

These applications highlight how NdFeB magnets boost performance by providing stronger, more efficient magnetic separation across multiple sectors in the U.S. industrial landscape.

How NBAEM’s NdFeB Magnets Stand Out for Magnetic Separators

NBAEM is known for delivering high-quality NdFeB magnets that perfectly fit the demands of magnetic separators. Their commitment to strict quality control and precise manufacturing ensures each magnet performs consistently, giving you reliable magnetic strength every time.

One of NBAEM’s key strengths is offering custom magnet solutions tailored exactly to your separator’s design and specifications. Whether you need a specific size, shape, or magnetic grade, they work closely with you to get it right.

Durability matters, especially in tough industrial settings. NBAEM uses advanced coatings to boost corrosion resistance, extending the magnet’s life even in wet or harsh environments. This means fewer replacements and less downtime for your operation.

Consistency in magnetic properties is critical for efficient separation. NBAEM’s manufacturing process guarantees uniform magnetic performance across batches, so you can count on steady, effective separation without surprises.

Beyond the product, NBAEM provides solid after-sales support. They partner with customers throughout the magnet’s lifecycle, offering technical advice and quick solutions when needed, making them a trusted choice for industrial buyers in the U.S. market.

Installation and Maintenance Tips for NdFeB Magnets in Magnetic Separators

Installing NdFeB magnets correctly is key to getting the most from your magnetic separator. Here are some straightforward tips to help you set up and maintain these powerful magnets safely and effectively:

Best Practices for Installation

- Handle with care: NdFeB magnets are brittle and can chip or crack if dropped. Use gloves and avoid sudden impacts during installation.

- Secure mounting: Make sure the magnets are firmly fixed in place to prevent movement during operation. Loose magnets can reduce separation efficiency and damage equipment.

- Follow polarity: Check that magnets are installed with proper polarity to maximize magnetic force and ensure optimal material separation.

- Avoid overheating: Don’t expose magnets to temperatures above their rated limits during installation or operation, as this can cause permanent loss of magnetism.

Routine Checks to Maintain Performance

- Visual inspection: Look for cracks, chips, or corrosion regularly. Damaged magnets can weaken magnetic strength and cause contamination risks.

- Magnetic strength test: Use a gauss meter to measure magnet strength at intervals. A drop could indicate demagnetization or damage.

- Clean surfaces: Keep both magnets and separator surfaces free from dirt, oil, or metal debris to maintain full magnetic force.

Common Challenges and Troubleshooting

- Demagnetization risk: High temperatures or strong opposing magnetic fields can weaken NdFeB magnets. Check operating conditions carefully.

- Corrosion: While many NdFeB magnets come with protective coatings, these can wear off. Reapply coatings or replace magnets if corrosion appears.

- Mechanical damage: Vibration or impacts during use may loosen or degrade magnets. Regularly check mountings and supports.

Longevity Optimization Tips

- Store spare magnets in dry, cool locations away from metal objects and heat.

- Schedule maintenance downtime for thorough inspections and cleaning.

- Use custom coatings or sleeves designed by your NdFeB magnet supplier to enhance corrosion and wear resistance.

- Work with manufacturers like NBAEM for tailored advice and support on magnet care.

Following these simple steps will keep your NdFeB magnets in magnetic separators running strong and efficient for years, saving you costs on repairs and downtime.

Comparing NdFeB Magnets to Other Magnet Types in Magnetic Separation

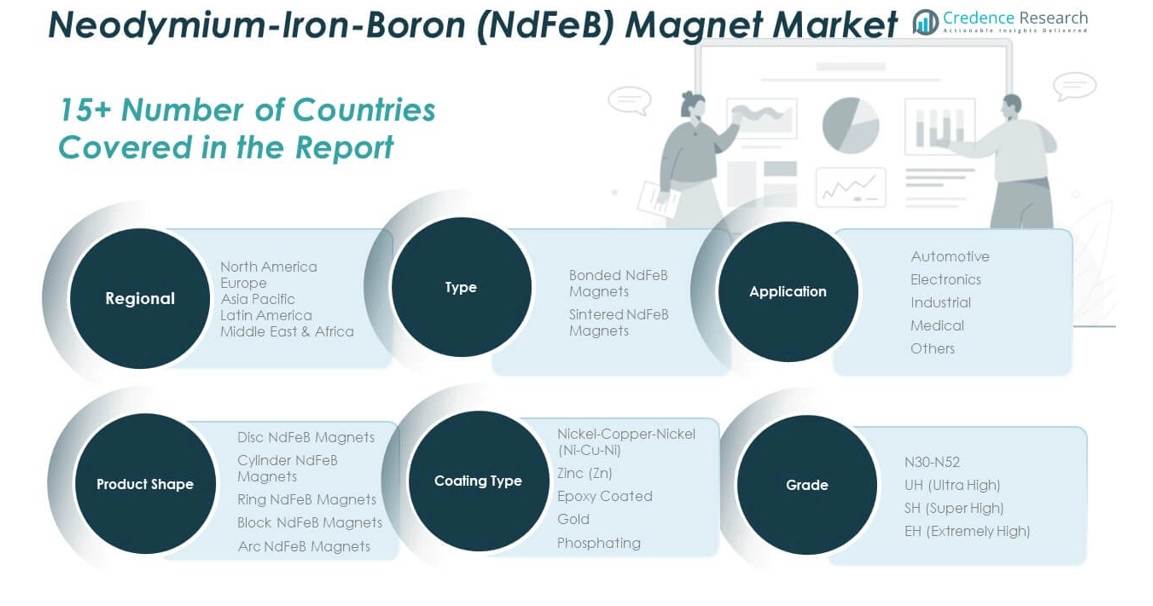

Photo from Credence Reserch.

When it comes to magnetic separators, choosing the right magnet can make a big difference. NdFeB magnets stand out compared to traditional magnet types like ferrite and Alnico, especially in cost versus performance.

Cost vs Performance

- NdFeB magnets tend to be more expensive upfront than ferrite magnets but offer much higher magnetic strength. That means better separation efficiency and smaller magnet sizes for the same power.

- Compared to Alnico and SmCo magnets, NdFeB offers stronger magnetic fields at a lower cost, making them a more practical choice for many industries.

- Over time, the improved throughput and lower energy needs of NdFeB separators can offset their initial price.

Application Specific Recommendations

- For heavy-duty mining or mineral processing, NdFeB magnets deliver superior pulling power, handling larger and denser material effectively.

- In recycling and food processing, NdFeB magnets provide sharper, cleaner separation, boosting quality and reducing contamination.

- For wet magnetic separators, coated NdFeB magnets resist corrosion better than other rare earth magnets, extending the device lifespan.

Case Studies of NBAEM NdFeB Magnets

- NBAEM’s NdFeB magnets have proven to outperform ferrite magnets in several U.S.-based recycling facilities, increasing metal recovery by over 15%.

- In automotive parts production, NBAEM customized NdFeB magnets helped improve separator uptime thanks to their durability and consistent magnetic strength.

- For chemical processing plants, NBAEM’s magnets maintained peak performance at higher temperatures where ferrite magnets tend to lose magnetism.

In short, for U.S. industrial buyers looking for high-performance, reliable magnetic separation, NdFeB magnets from NBAEM are a proven, cost-effective choice when considering total value and efficiency.

How to Choose the Right NdFeB Magnet for Your Magnetic Separator

Picking the right NdFeB magnet for your magnetic separator means balancing several key factors that affect performance and durability. Here’s what you need to focus on:

Key Factors to Consider

| Factor | What to Look For |

|---|---|

| Size and Shape | Must fit your separator’s design for optimal flux |

| Magnet Grade | Higher grades (e.g., N52) offer stronger magnetic force |

| Coating Type | Look for corrosion-resistant coatings like Ni-Cu-Ni to extend lifespan |

| Temperature Tolerance | Choose magnets rated for your operating temps (up to 80-200°C) |

| Magnetic Strength | Sufficient pull force for the materials you separate |

Why These Matter

- Size and shape: A magnet too big or small won’t work efficiently. Custom shapes improve contact with materials.

- Grade: Higher grades mean stronger magnets but can be pricier.

- Coating: Essential for preventing rust, especially in wet or harsh industrial environments.

- Temperature tolerance: NdFeB magnets lose strength if exposed to temperatures above their rating.

- Strength: Must match separation needs—too weak is ineffective, too strong might over-extract and slow throughput.

Working with NBAEM’s Expert Team

NBAEM offers tailored solutions to make sure your magnet fits your separator perfectly. Their experts can help:

- Assess your magnetic separation needs

- Recommend the right NdFeB grade and coating

- Customize magnet sizes and shapes

- Provide technical support during installation and maintenance

Procurement Tips for Industrial Buyers

- Request samples to test in your separators before bulk buy

- Verify magnetic specs and certifications to ensure quality

- Consider lead times especially for custom orders from China suppliers like NBAEM

- Discuss after-sales support and warranty terms upfront

Choosing the right NdFeB magnet means getting the balance of power, durability, and fit right—partnering with a reliable supplier like NBAEM helps make that process smooth and effective.

Leave A Comment