Overview of NdFeB Magnet Technology

NdFeB magnets, short for neodymium-iron-boron magnets, are the strongest type of permanent magnets available today. Their composition includes neodymium (Nd), iron (Fe), and boron (B), which together create a powerful magnetic material known for its high magnetic energy product. This means NdFeB magnets offer exceptional magnetic strength relative to their size.

Key fundamental properties of NdFeB magnets include:

- High remanence: They retain strong magnetization even without an external magnetic field.

- High coercivity: They resist demagnetization under various operating conditions.

- Excellent magnetic energy product: This measures their maximum energy density, making them highly efficient in compact applications.

Due to these properties, NdFeB magnets are indispensable in many industries. Major demand drivers include:

- Electronics: They power everything from hard drives to speakers and wearables, offering compact, efficient magnet performance (see magnets used in electronics and computers).

- Automotive: Especially in electric vehicles (EVs), NdFeB magnets enable lighter, more powerful motors leading to better energy efficiency.

- Renewable energy: Wind turbine generators heavily rely on strong permanent magnets like NdFeB to maximize power output and reduce maintenance needs.

The combination of material efficiency and versatile applications makes NdFeB magnets a critical component in the modern tech-driven economy, fueling growth in multiple cutting-edge fields.

Challenges in Traditional NdFeB Magnet Technologies

Traditional NdFeB magnets face several challenges, especially concerning temperature sensitivity. These magnets tend to lose strength as temperatures rise, which limits their use in high-heat environments like automotive engines and some industrial motors. Corrosion is another issue—NdFeB magnets can degrade quickly when exposed to moisture or harsh conditions without proper protection, impacting reliability and lifespan.

Another major challenge is the reliance on critical raw materials, mainly rare earth elements such as neodymium, dysprosium, and terbium. These elements are often sourced from limited regions, raising concerns about supply risks and price volatility, especially for U.S. manufacturers dependent on imports. This supply chain uncertainty makes sustainability and cost management tricky.

Environmental and cost concerns also weigh heavily on traditional NdFeB magnet production. Mining and processing rare earth materials have significant environmental footprints. Manufacturers in the U.S. market are increasingly focused on finding solutions that reduce waste, energy use, and hazardous byproducts without driving costs up.

Emerging Magnetic Technologies and Innovations Advanced Coating and Surface Treatment Technologies

New magnetic coating technologies are making a big impact on NdFeB magnets, especially when it comes to corrosion resistance. Traditional coatings often fall short in harsh environments, leading to rust and faster degradation. Today’s advanced coatings use innovative materials that significantly boost corrosion protection, helping magnets last longer even under tough conditions.

Some of the latest surface treatments also enhance durability by creating tougher, more wear-resistant layers. These treatments reduce the chance of surface damage during handling or use, which means the magnet’s performance stays stable over time.

Key benefits of these coatings and surface treatments include:

- Improved resistance to moisture and chemicals

- Extended operational lifespan in automotive and renewable energy applications

- Better performance under temperature and mechanical stress

- Less need for frequent replacements, cutting overall costs

By adopting these advanced techniques, manufacturers can deliver NdFeB magnets that stand up to demanding U.S. industries, from electronics to automotive, where reliability and durability are critical.

Emerging Magnetic Technologies and Innovations Composition and Material Innovations

New magnetic technologies for NdFeB magnets are focusing heavily on changing what these magnets are made of to tackle issues like high cost and supply risks. One approach is developing rare earth reduced or even rare earth free magnetic alternatives. These alternatives aim to keep strong magnetic performance while using fewer or no critical rare earth elements, which are often subject to supply chain vulnerabilities, especially from China.

To boost temperature resistance—a weak spot for traditional NdFeB magnets—manufacturers are incorporating substitutes such as dysprosium and terbium. These elements help magnets maintain their strength and stability in high-heat settings like electric motors and renewable energy generators.

Another exciting development is the use of nano structured magnetic materials. By engineering magnets at the nanoscale, these materials can significantly enhance magnetic properties, including coercivity and energy product. This means stronger magnets with potentially smaller sizes – a big advantage in electronics and automotive industries.

Emerging Magnetic Technologies Manufacturing and Processing Enhancements

In the world of NdFeB magnet innovation, manufacturing and processing advancements are making a real impact on performance and production efficiency. One key development is hot deformation and grain boundary diffusion technology, which improves the magnet’s microstructure. This leads to stronger magnetic properties and better high-temperature performance—something crucial for applications in automotive and renewable energy sectors.

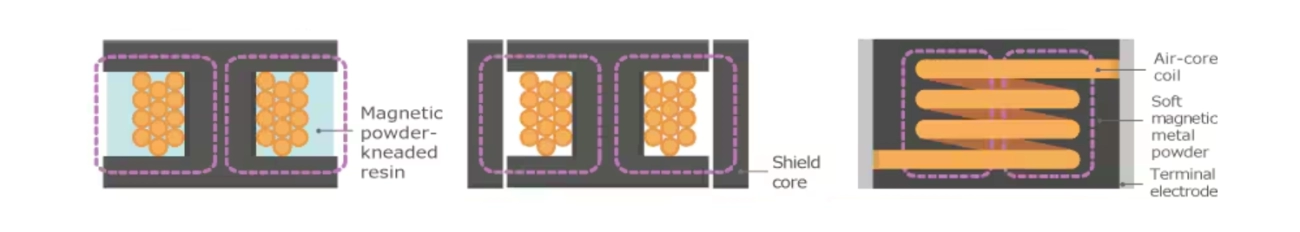

Another breakthrough is in additive manufacturing and 3D printing for magnets. These methods allow precise shaping and customization that traditional manufacturing can’t match. With 3D printing, complex magnet shapes can be produced faster, reducing waste and lowering costs. This tech also supports creating anisotropic magnets, which have directional magnetic properties tailored to specific uses.

Precision machining and anisotropic magnet fabrication further enhance the quality and consistency of NdFeB magnets. Precision machining ensures tight tolerances and smooth finishes, essential for high-performance electronics and motors. Creating anisotropic magnets—where magnetic grains are aligned—helps maximize output in compact spaces, a big advantage in U.S. industries focusing on miniaturization.

Together, these manufacturing innovations are pushing NdFeB magnets to new levels in durability, efficiency, and application flexibility. For those interested in magnet production methods, check out NBAEM’s detailed guide on how to make NdFeB magnet, which covers these processes in depth.

Emerging Magnetic Technologies and Innovations Sustainable and Environment Friendly Technologies

Sustainability is becoming a top priority in NdFeB magnet innovation. Recycling and reusing rare earth materials help reduce dependency on limited resources and lower environmental impact. Many companies now focus on efficient methods to recover neodymium, dysprosium, and other critical elements from used magnets, cutting waste and preserving raw materials.

Energy-efficient production processes play a major role in greener manufacturing. State-of-the-art techniques reduce energy consumption during magnet fabrication without compromising quality. These include optimized sintering methods and eco-friendly bonding agents that minimize harmful emissions.

By combining recycling efforts and cleaner production, new magnetic technologies support both environmental goals and cost savings. This shift makes NdFeB magnets more sustainable and helps meet growing demand from U.S. industries aiming for greener solutions.

Case Studies Implementation of New Technology in NdFeB Magnets

NBAEM has been at the forefront of applying new magnetic technologies to NdFeB magnets, delivering products that stand out in both performance and cost-efficiency. Here are some examples where advanced innovations made a real difference:

Advanced NdFeB Products with Enhanced Properties

- High-Temperature NdFeB Magnets: NBAEM’s integration of dysprosium substitutes and nano structured materials has raised the operating temperature range significantly. This means magnets now maintain strength and stability in demanding automotive and renewable energy applications, meeting US market requirements for heat resistance.

- Improved Corrosion-Resistant Magnets: Through proprietary coating technologies and surface treatments, NBAEM’s magnets resist rust and degradation better than traditional designs. This improvement extends the magnets’ lifespan, especially in harsh environments like marine or industrial uses.

Customer Success Stories

- Automotive Industry: A leading US electric vehicle manufacturer reported a 15% increase in motor efficiency using NBAEM’s hot-deformed anisotropic NdFeB magnets. These magnets also helped reduce the overall motor weight, contributing to better battery range and performance.

- Wind Energy Sector: A renewable energy company utilizing NBAEM’s magnets with advanced grain boundary diffusion techniques improved generator reliability, cutting maintenance costs by 20% annually.

- Consumer Electronics: NBAEM worked with a US electronics firm to develop customized magnets with precise machining and tailored magnetic grades, resulting in smaller, more powerful motors for portable devices.

These examples showcase how NBAEM’s innovations are driving real-world benefits—enhancing product reliability, boosting efficiency, lowering costs, and supporting sustainable practices vital for the US market. Learn more about how magnets power modern technology in our Permanent Magnet Applications in Modern Technology article.

Future Trends and R&D Directions in NdFeB Magnet Technologies

Research in NdFeB magnet innovation is moving fast, especially toward magnets that perform better at high temperatures. High temperature NdFeB magnets are critical for applications like electric vehicles and renewable energy, where durability under heat is a must. Scientists are working on new compositions and material tweaks to push the temperature limits without relying heavily on scarce rare earth elements.

Smart manufacturing is another key area changing the game. Using AI and machine learning helps improve quality control during magnet production, ensuring consistency and reducing defects. This integration allows real-time monitoring and faster adjustments in processes like grain boundary diffusion or hot deformation, which boost magnetic properties.

Emerging materials also hold promise. Researchers are exploring nano structured magnetic materials and rare earth alternatives that could offer similar or better performance with less environmental impact. These breakthroughs could reshape the NdFeB magnet market, making magnets more sustainable and cost-effective for industries across the U.S.

By following these trends, the future of NdFeB magnets combines smarter production, better materials, and higher performance features tailored for demanding applications. For more on high temperature solutions, see our page on high temperature magnets.

Leave A Comment