Basic Principles How Electricity is Generated Using Magnets What Is a Generator

At its core, a generator is a device that converts mechanical energy into electrical energy. This conversion relies heavily on magnets and the interaction between magnetic fields and conductors. Simply put, when a conductor such as a wire coil moves through a magnetic field, it induces an electric current—a process essential for producing electricity.

Generators are everywhere—from power plants to small backup units powering homes. Despite their variety, all generators operate on one fundamental principle: electromagnetic induction. This means that magnets and coils work together to create a flow of electricity without direct contact, making the process efficient and reliable.

Understanding what a generator is and how it works helps clarify the vital role magnets play in power generation. In everyday terms, think of turning a handle or a turbine spinning. That motion moves magnets or coils so that electricity is produced. This simple yet powerful idea forms the backbone of modern electrical systems, delivering energy to everything from appliances to industrial machinery.

Basic Principles How Electricity is Generated Using Magnets Fundamentals of Magnetism and Electromagnetism

To understand how a generator works, it helps to know a bit about magnetism and electromagnetism. Magnets create magnetic fields, invisible forces that can push or pull certain metals like iron. In a generator, these magnetic fields interact with coils of wire to produce electricity.

Electromagnetism ties together electricity and magnetism. When an electric current flows through a wire, it creates a magnetic field around it. Likewise, moving a wire through a magnetic field—or changing the magnetic field near a wire—causes electricity to flow in that wire. This is the basic idea behind electromagnetic induction in generators.

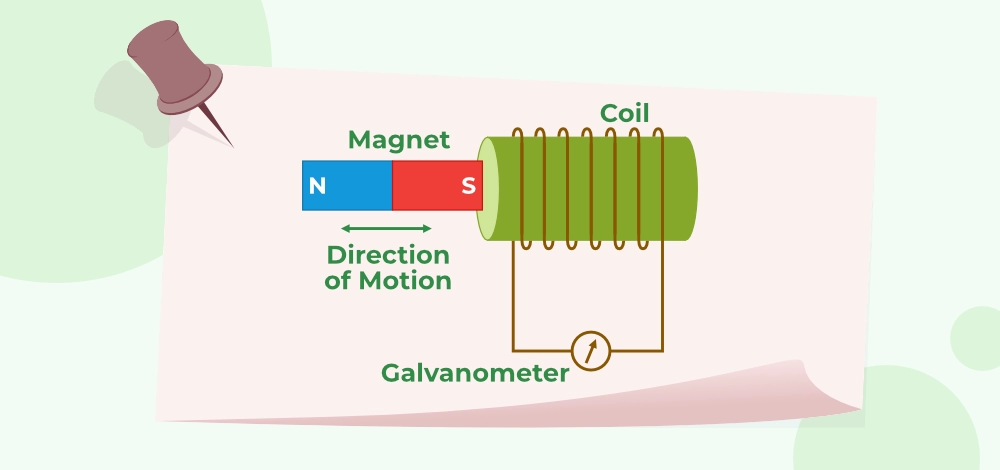

Electromagnetic Induction The Core Concept

Electromagnetic induction is the main idea behind how magnets work in a generator. When a magnet moves near a coil of wire, it creates a changing magnetic field. This change in the magnetic field causes electric current to flow in the wire. This process is called electromagnetic induction.

Here’s why it matters: as the magnet spins or moves inside the generator, it constantly changes the magnetic flux through the coil. This shifting magnetic flux generates electricity. Without this interaction between the magnet and the coil, no power would be produced.

This principle works in all types of generators, whether they use permanent magnets or electromagnets. The key is having a magnetic field that changes relative to the wire coil to induce a steady flow of electric current. So, understanding electromagnetic induction is essential to grasp how generators produce electricity using magnets.

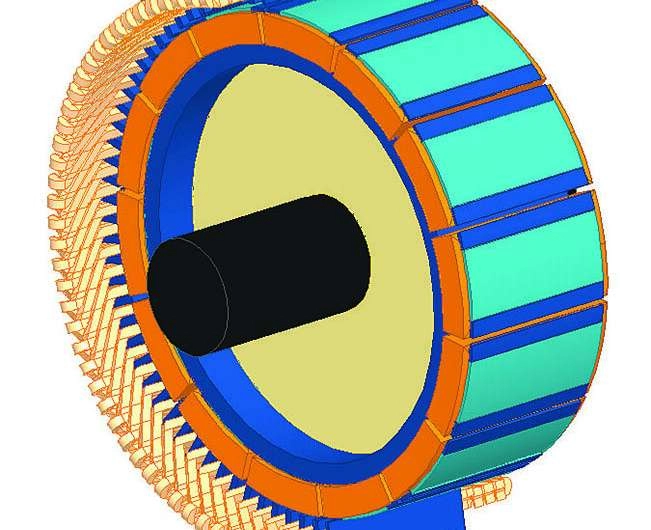

Role of Magnets in Different Types of Generators Permanent Magnet Generators PMGs

Permanent Magnet Generators (PMGs) use magnets that keep their magnetic field without needing extra power. These magnets are usually made from strong materials like neodymium, which provide a steady magnetic flux. In a PMG, the magnets spin around a coil or the coil spins inside a magnetic field. This movement causes electromagnetic induction, which produces electricity.

Key features of PMGs with magnets:

- No external power needed: Magnets create the magnetic field on their own.

- High efficiency: Strong permanent magnets improve power output.

- Compact design: Fewer parts, so PMGs usually weigh less and are smaller.

- Low maintenance: No brushes or extra power for the magnetic field means less wear and tear.

PMG magnet types commonly used:

| Magnet Type | Strength | Common Use | Cost |

|---|---|---|---|

| Neodymium (NdFeB) | Very High | Wind turbines, portable gens | Higher |

| Ferrite | Moderate | Small generators | Lower |

| Alnico | Moderate-High | Specialized applications | Moderate |

The strong magnetic field from permanent magnets directly influences the generator coil, creating a steady and reliable current. PMGs are a popular choice in modern renewable energy systems and portable power solutions because they combine simplicity with high performance.

Role of Magnets in Different Types of Generators Electromagnetic Generators

Electromagnetic generators use magnets differently from permanent magnet generators. Instead of fixed magnets, these generators rely on electromagnets—coils of wire energized by an electric current to create a magnetic field. This setup gives more control over the magnet’s strength, which can be adjusted by changing the current flowing through the coils.

Here’s how magnets work in electromagnetic generators:

- Magnetic Field Creation: Electromagnets generate a magnetic field around the rotor or stator.

- Magnetic Flux Variation: As parts spin, the electromagnetic field interacts with coils in the stator or rotor to produce changing magnetic flux.

- Electricity Generation: The changing magnetic flux induces electric current in the generator’s coils, thanks to electromagnetic induction.

This system allows for:

| Feature | Description |

|---|---|

| Adjustable Field | Magnetic strength can be tuned for optimal output |

| Larger Scale Use | Ideal for big power plants and industrial setups |

| Maintenance | Requires power to maintain magnetism, slight energy cost |

Electromagnetic generators are common in power plants because they can handle high capacities and provide flexibility in control. Unlike permanent magnets, electromagnetic setups don’t rely on fixed magnets, making them adaptable but dependent on an external power source to keep the magnets energized.

This flexibility is vital for meeting varying power demands in the U.S. energy grid, where reliability and control are key to stable electricity supply.

Role of Magnets in Different Types of Generators Hybrid Systems and Advanced Designs

Hybrid generators combine features from both permanent magnet generators (PMGs) and electromagnetic generators to improve efficiency and flexibility. In these advanced designs, magnets play a crucial role by working alongside electromagnets to optimize power output.

How Hybrid Systems Use Magnets

- Permanent magnets provide a constant magnetic field without needing external power, which reduces energy loss.

- Electromagnets adjust the magnetic field strength dynamically, allowing better control over output voltage and current.

- This combination helps the generator manage varying loads and speeds more effectively than traditional designs.

Advantages of Hybrid Magnet Systems

| Feature | Benefit |

|---|---|

| Stable magnetic flux | Consistent power output |

| Adjustable magnetic fields | Better control and efficiency under load |

| Reduced energy consumption | Lower operating costs |

| Enhanced durability | Longer generator lifespan |

Hybrid generators are common in wind turbines and other renewable energy setups where fluctuating conditions demand adaptable magnet performance.

Why Quality Magnetic Materials Matter NBAEM’s Contribution Magnetic Material Types Used in Generators

The quality of magnetic materials plays a big role in how well generators perform. NBAEM offers a variety of magnetic materials tailored specifically for electric generators, helping improve efficiency and durability. Some common types of magnets used in generators include:

- Neodymium Magnets (NdFeB): Known for their strong magnetic fields and high energy density, neodymium magnets are popular in permanent magnet generators (PMGs). They enable smaller, lighter generators without sacrificing power output.

- Ferrite Magnets: More affordable and corrosion-resistant, ferrite magnets are common in many generators but offer lower magnetic strength compared to neodymium.

- Samarium Cobalt Magnets: Ideal for high-temperature environments, these magnets maintain magnetic properties even under intense heat, making them suitable for certain heavy-duty generators.

NBAEM specializes in providing these magnetic materials with consistent quality, catering to different generator needs across the U.S. market. Their materials ensure stable magnetic flux, which directly impacts the generator coil and magnet interaction, leading to reliable electricity production. For American manufacturers and users, getting magnetic materials from NBAEM means access to both cost-effective and high-performance options suited to various power generation systems.

Material Performance and Generator Efficiency

The quality of magnetic materials plays a big role in how well a generator performs. Stronger and more stable magnets create a stronger magnetic field, which means better electromagnetic induction in generators. This boosts the power output and overall efficiency of the device.

NBAEM provides high-grade magnetic materials known for their excellent magnetic flux density and temperature stability. These properties help generators maintain performance even under tough conditions, like high heat or continuous use. Using materials like neodymium magnets from NBAEM improves the magnetic field strength, making permanent magnet generators (PMGs) and electromagnetic generators more reliable and efficient.

Better magnetic materials also reduce energy losses inside the generator. This means less wasted power and more energy sent to your home or business. In a market where every watt counts, NBAEM’s materials help optimize the generator’s output, supporting cleaner and more cost-effective power production.

Why Quality Magnetic Materials Matter NBAEM’s Contribution Custom Solutions for Various Generator Applications

Every generator application is unique, and choosing the right magnetic materials is key to maximizing performance. NBAEM understands this well, offering custom magnetic solutions tailored to fit specific generator needs across different industries in the U.S. market.

Whether it’s a compact permanent magnet generator for renewable energy or a large electromagnetic generator for industrial use, NBAEM provides magnets with properties suited for optimal magnetic flux and durability. These custom magnets help improve power output, efficiency, and reliability, meeting exact specifications like size, shape, coercivity, and temperature resistance.

NBAEM works closely with clients to select the best magnet types—including neodymium magnets known for their strong magnetic fields or bonded magnets designed for specialized shapes and applications. This flexibility allows manufacturers and maintenance teams to find the perfect balance between cost, performance, and longevity.

By offering tailored magnetic material solutions, NBAEM supports generators in delivering consistent power while reducing maintenance needs and wear. This approach benefits local U.S. customers looking for dependable, high-quality magnets for diverse generator designs.

For more details on how magnet types affect performance, you might find NBAEM’s insights on types of magnetic materials useful.

Practical Insights How Magnets Affect Generator Performance Efficiency and Power Output

Magnets play a major role in how well a generator performs, directly impacting both efficiency and power output. Stronger magnets create a more intense magnetic field, which helps generate more electricity from the same amount of mechanical energy. This means the generator can produce higher power without needing extra fuel or input energy.

Permanent magnets, especially those made from high-quality materials like neodymium, offer consistent magnetic strength and improve efficiency by reducing energy loss during operation. This leads to better power output and less heat generation, which keeps the generator running smoothly for longer periods. On the other hand, weaker or lower-grade magnets can cause the generator’s output to drop, making it less reliable and more costly to operate.

Magnetic flux—the amount of magnetic field passing through the generator coil—is a key factor influenced by magnet quality. Optimizing magnetic flux increases the voltage and current produced, improving overall efficiency. This is why many modern generators use advanced magnetic materials, such as those described in NBAEM’s selection of magnetic materials for electric generators, to maximize performance.

In short, the efficiency and power output of a generator heavily rely on the magnets’ strength and quality. Choosing the right magnets not only boosts electrical generation but also helps reduce wear, lowering maintenance needs and extending the generator’s life.

Longevity and Maintenance Considerations

Magnets play a big role in how long a generator performs well and how much upkeep it needs. Permanent magnets, like neodymium magnets used in many generators, don’t require extra power to maintain the magnetic field, which lowers wear and tear. This means fewer mechanical parts experience stress, helping the generator last longer.

Electromagnetic generators, on the other hand, rely on coils and electrical current to create magnetic fields. These parts can wear out over time due to heat and electrical load, making regular maintenance necessary to prevent failure. Checking connections and coil conditions often keeps the system running smoothly.

Using high-quality magnetic materials also reduces the risk of demagnetization, which can happen from heat or strong impacts. This protects generator efficiency and lowers the chance of costly repairs or replacements.

In short, well-chosen magnets cut down maintenance efforts and extend generator life, making them a smart choice for anyone depending on reliable power in the U.S. market.

Practical Insights How Magnets Affect Generator Performance Environmental and Economic Benefits

Magnets play a key role in making generators not only efficient but also eco-friendly and cost-effective. Here’s how quality magnets impact both the environment and your wallet:

Environmental Benefits

- Lower energy waste: Strong magnets improve electromagnetic induction, which means more electricity is produced with less input energy.

- Reduced carbon footprint: Efficient generators consume less fuel or rely more on renewable sources, cutting greenhouse gas emissions.

- Quiet operation: Permanent magnet generators (PMGs) tend to run quieter, reducing noise pollution in residential and sensitive areas.

- Longer lifespan: Durable magnetic materials mean fewer replacements and less waste over time.

Economic Benefits

| Benefit | Explanation |

|---|---|

| Higher efficiency | Better magnets boost power output, lowering energy costs. |

| Reduced maintenance | Stable magnetic properties minimize downtime and repair expenses. |

| Longer service life | Quality materials reduce need for frequent replacements. |

| Lower fuel consumption | Efficient magnets cut fuel usage in generators powered by combustion. |

Investing in high-grade magnetic materials helps deliver reliable power with less environmental impact and lower operating costs. This balance is especially important for U.S. households and businesses aiming for sustainable, affordable energy solutions.

Common Misconceptions and FAQs about Magnets in Generators

Many people misunderstand how magnets work inside generators. Here are some common misconceptions cleared up and quick answers to frequent questions.

Misconception 1: Magnets produce electricity on their own

Magnets don’t create electricity by themselves. They help generate electricity by creating a magnetic field that interacts with coils of wire. This interaction, called electromagnetic induction, is what actually produces electric current.

Misconception 2: Stronger magnets always mean a better generator

While strong magnets like neodymium magnets improve efficiency, other factors such as coil design, rotation speed, and material quality also play crucial roles. Simply using stronger magnets isn’t a guarantee of higher power output.

Misconception 3: All generators use permanent magnets

There are many types of generators. Some use permanent magnets (like PMGs), while others rely on electromagnets that need an external power source to create their magnetic field. Hybrid systems combine both for better performance.

FAQ 1: How long do magnets last in generators?

Quality magnets, especially rare-earth types, can last many years without significant loss of magnetism. However, factors like heat and physical damage can reduce their lifespan. Learn how long neodymium magnets last for more insights.

FAQ 2: Can magnets in generators demagnetize over time?

Yes, magnets can lose strength due to heat, strong external magnetic fields, or physical shock. But good-quality magnets are made to resist this. You can also remagnetize some magnets if needed.

FAQ 3: Why do some generators use electromagnets instead of permanent magnets?

Electromagnets allow control over the magnetic field strength, which is helpful for larger generators or where variable power output is needed. However, they require additional energy to power the magnets themselves.

FAQ 4: What types of magnets are commonly used in generators?

Permanent magnets like neodymium, samarium-cobalt, and ceramic magnets are popular in smaller to mid-sized generators. Bigger power plants often use electromagnets due to the need for adjustable fields.

Leave A Comment