Permanent Magnet Generators (PMGs) are innovative machines that convert mechanical energy into electrical power using permanent magnets to generate a magnetic field. Unlike traditional generators that rely on external power sources or induction mechanisms, PMGs leverage the intrinsic properties of permanent magnets, resulting in higher efficiency, lower maintenance, and broader applicability. This article explores the components, working principles, types, benefits, and applications of permanent magnet generators, highlighting their growing significance in modern energy systems.

Components of Permanent Magnet Generators

A PMG is composed of several key components that work together to efficiently convert mechanical energy into electrical power:

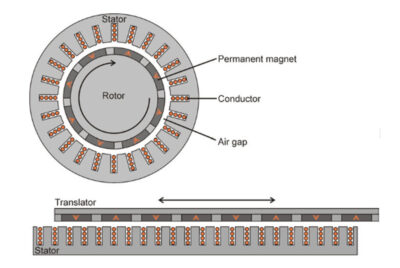

- Rotor: The rotor is equipped with permanent magnets, usually made of materials such as neodymium, samarium-cobalt, or ferrite. These magnets provide a fixed magnetic field that turns as the rotor spins, creating the essential movement needed for power generation.

- Stator: The stator encloses the rotor and contains copper windings (coils). As the rotor spins and its magnetic field interacts with the stator, an electric current is induced in the stator windings, creating electrical power.

- Bearings: Bearings help the rotor rotate smoothly inside the stator by reducing friction. High-quality bearings can extend the life of the generator by reducing wear and tear.

- Cooling System: To prevent overheating during operation, PMGs often include a cooling system to ensure peak performance and protect internal components from heat damage.

Working Principles of Permanent Magnet Generators

The conversion of mechanical energy into electrical energy in a PMG occurs through the following steps:

- Mechanical Energy Input: Mechanical energy, such as wind or the flow of water, is applied to the shaft of the rotor, causing it to turn.

- Magnetic Field Interaction: The spinning rotor, with its magnets embedded in it, produces a moving magnetic field. This magnetic field interacts with the stationary windings in the stator, creating an electric current.

- Current Generation: As the magnetic field from the rotor passes through the windings in the stator, it creates voltage, generating electrical energy.

- Control Systems: A control system manages the output of the generator, ensuring that the electrical power produced is stable and suitable for the intended application.

Types of Permanent Magnet Generators

PMGs come in different designs, each suited for specific applications and performance requirements:

Brushless PMGs: These generators eliminate the need for brushes and slip rings, resulting in lower maintenance requirements and longer life. They are commonly used in applications where long-term reliability is critical.

Axial Flux PMGs: Axial flux generators are known for their compact and lightweight design, making them suitable for industries like automotive and aerospace where space and weight are at a premium.

Radial Flux PMGs: The most common design, radial flux generators, are used extensively in wind turbines and other industrial applications due to their robust construction and high power output.

High-Speed PMGs: These generators are designed to operate at high rotational speeds and are used in compact systems that require a high power-to-weight ratio, such as micro-turbines and small-scale power generation.

Low-Speed PMGs: These generators are optimized for low rotational speeds and are commonly used in hydroelectric power systems, where consistent power generation at slow speeds is critical.

Benefits of Permanent Magnet Generators

The growing popularity of PMGs is due to their many advantages over traditional generators, including:

- Free Energy Source: PMGs capture energy from the inherent magnetic fields created by permanent magnets, eliminating the need for an external power source. This ability allows users to generate electricity on their own, potentially reducing their reliance on the grid and lowering energy costs.

- Reliable Energy Output: Unlike generators that rely on variable energy sources like solar or wind, PMGs produce a consistent output, making them reliable even in unfavorable weather conditions. This characteristic makes them well-suited for off-grid and remote applications.

- Low Installation Costs: PMGs are relatively easy to install. Many designs are compact and can be built from components found at your local hardware store, making them a cost-effective option for small-scale energy production.

- Minimal Maintenance: PMGs do not have moving parts like brushes and slip rings that can wear out. As a result, they require less maintenance and are more durable than traditional generators.

Applications of Permanent Magnet Generators

Due to their high efficiency, reliability, and low maintenance requirements, PMGs are used in a variety of applications across multiple industries:

- Wind Turbines: PMGs are commonly used in wind energy systems, where they convert the mechanical energy from the rotating blades into electrical power efficiently. Their durability and low maintenance make them ideal for large-scale wind farms.

- Hydropower: In small-scale hydropower systems, PMGs convert the kinetic energy from flowing water into electrical energy. Their robust design and efficiency ensure reliable operation in off-grid and remote locations.

- Electric Vehicles: PMGs are used in electric vehicle (EV) systems to generate electricity during regenerative braking, improving overall energy efficiency and extending battery life.

- Portable Generators: Because of their small size and high efficiency, PMGs are used in portable generators for camping, outdoor activities, and emergency power backup.

- Marine Applications: PMGs can capture wave or tidal energy in marine environments to generate electricity for offshore installations. Their ability to withstand harsh conditions makes them well-suited for maritime applications.

Comparison with Induction Generators

While both permanent magnet and induction generators convert mechanical energy into electrical power, they operate on different principles:

Permanent Magnet Generators: PMGs create their own magnetic field by using permanent magnets. This characteristic makes them more efficient and less reliant on external power sources.

Induction Generators: Induction generators need an external power source to create a magnetic field. While they are widely used in various applications, they are generally less efficient than PMGs since they require additional energy input.

Conclusion

Permanent Magnet Generators are a significant advancement in energy generation technology. Their ability to provide efficient, reliable, and low-maintenance power makes them an attractive solution for a wide range of applications, from renewable energy systems like wind and hydropower to electric vehicles and portable power sources. As the demand for clean and sustainable energy increases globally, PMGs are poised to play a crucial role in meeting these needs, offering both environmental and economic benefits.

NBAEM magnets, a trusted supplier of high-quality permanent magnets and related components, provides custom solutions for PMGs and other magnetic applications. With decades of experience, they are well-positioned to support the growing demand for advanced energy generation technologies.

Permanent Magnet Generator

Leave A Comment