Understanding Coreless Motors

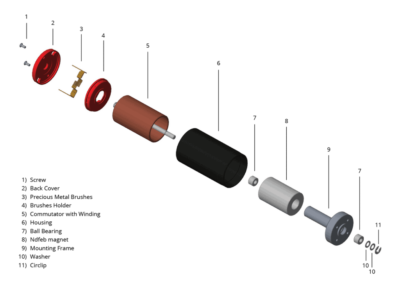

Coreless motors, also known as coreless DC motors or ironless motors, are a unique category of electric motors designed without the traditional iron core in their rotor. Instead, their rotor windings are tightly wound and supported on a lightweight, non-magnetic former, which significantly reduces the motor’s overall mass and inertia.

Fundamental Working Principles

Unlike conventional motors, where the rotor includes an iron core to carry the magnetic flux, coreless motors rely on stationary permanent magnets to produce the magnetic field. The current flowing through the rotor windings interacts with this magnetic field, generating torque that causes rotation. The absence of iron in the rotor means:

- No magnetic hysteresis losses

- Lower eddy current losses

- Faster acceleration and deceleration

Differences Between Coreless and Traditional Core Motors

| Feature | Coreless Motor | Traditional Core Motor |

|---|---|---|

| Rotor Composition | Ironless, winding on non-magnetic former | Iron core with winding around it |

| Weight | Significantly lighter | Heavier due to iron core |

| Inertia | Reduced rotor inertia for quicker response | Higher inertia slows dynamic response |

| Efficiency | Higher efficiency with lower energy losses | Moderate efficiency due to core losses |

| Heat Dissipation | Better thermal management due to lightweight | Heat builds up in the iron core |

Benefits of Coreless Motors

- Weight Reduction: Elimination of iron core reduces weight, enabling compact and lightweight designs ideal for portable or precision applications.

- Improved Efficiency: Less energy lost to heat and magnetic losses, resulting in better power utilization.

- Reduced Inertia: Lower moment of inertia allows for rapid speed changes, enhancing motor responsiveness and control precision.

Coreless motors represent a significant advancement in motor design, providing performance benefits that suit industries demanding high power density and precision. For a deeper look into permanent magnetism fundamentals that support such designs, visit What is Permanent Magnetism.

Permanent Magnets An Integral Component in Coreless Motors

Permanent magnets are crucial in coreless motor design. These magnets are materials that produce a constant magnetic field without needing external power. Common types include Neodymium (NdFeB), Samarium-Cobalt (SmCo), and Ferrite. Each offers different magnetic strength and thermal resistance, which affect motor performance.

In coreless motors, permanent magnets are placed in the rotor or stator to create a steady magnetic flux. This magnetic flux interacts with the motor’s windings, producing the torque needed for rotation. Unlike traditional motors, coreless designs rely heavily on these magnets to generate strong, focused magnetic fields because they lack an iron core.

The specific roles of permanent magnets in coreless motors include:

- Generating magnetic flux: They supply the continuous magnetic field essential for motor operation.

- Producing torque: The interaction between the magnetic flux and the current in the windings creates rotational force.

- Reducing loss: High-quality magnets help improve efficiency by maintaining consistent magnetic strength and minimizing heat buildup.

By integrating the right permanent magnet materials, coreless motors achieve high performance, better responsiveness, and improved overall reliability, which makes them ideal for applications needing precision and efficiency.

Impact of Permanent Magnets on Coreless Motor Performance

Permanent magnets play a crucial role in boosting the performance of coreless motors. Their strong magnetic flux directly enhances the motor’s efficiency and power density, allowing it to deliver more power while keeping the size compact. This means coreless motors can run longer on less energy, a key advantage for battery-powered devices used in the U.S. market.

Heat dissipation is another area where permanent magnets make a difference. Because coreless motors lack an iron core, managing heat can be tricky. High-quality magnets, especially those with good thermal stability like Neodymium or SmCo, help maintain consistent magnetic strength even under elevated temperatures, improving overall thermal reliability. This stability reduces the risk of overheating and extends the motor’s lifespan, important for demanding applications like robotics or electric vehicles.

Responsiveness and reliability also benefit from the use of top-grade permanent magnets. The strong, consistent magnetic fields they produce allow for quicker torque generation. This means the motor reacts faster to control inputs, delivering smooth acceleration and precise control—critical in medical devices, drones, and automation. Plus, durable magnets ensure the motor’s magnetic properties stay stable over time, reducing maintenance needs and downtime.

For more insights on magnetic materials and how they impact motor efficiency, you can check NBAEM’s overview for types of magnets and learn why Neodymium magnets are often preferred in performance-driven applications.

Material Considerations for Permanent Magnets in Coreless Motors

When selecting permanent magnets for coreless motors, the most common materials are NdFeB (Neodymium Iron Boron), SmCo (Samarium-Cobalt), and Ferrite. Each offers unique magnetic properties suited for different motor needs.

- NdFeB (Neodymium) magnets stand out for their high energy product, meaning they generate strong magnetic fields in a compact size. This makes them ideal for coreless motors where weight and space are critical.

- SmCo magnets offer great thermal resistance and stability, performing well in high-temperature environments, although they come at a higher cost.

- Ferrite magnets are more affordable but have lower magnetic strength, so they’re less common in high-performance coreless motor designs.

For coreless motors, Neodymium magnets are often the top choice because they balance power density and temperature tolerance, helping improve motor efficiency and reliability.

NBAEM provides a strong portfolio of advanced magnetic materials, including high-grade NdFeB magnets. Their local manufacturing in China supports shorter lead times and customization options, which is a plus for US customers looking for tailored solutions with consistent quality.

Technological Innovations and Trends

The world of permanent magnets in coreless motors is evolving fast. One of the biggest shifts is the move toward rare-earth-free or low-rare-earth magnets. These materials help reduce dependence on costly and sometimes hard-to-source rare-earth elements, making motors more sustainable and affordable for U.S. manufacturers.

Beyond material changes, there are improvements in how magnets are shaped, coated, and magnetized. These advances allow magnets to fit better within compact coreless motor designs while boosting durability and performance. For example:

- Precision magnet shaping improves magnetic flux distribution, enhancing torque and efficiency.

- Advanced coatings protect magnets from corrosion and wear, extending motor life.

- Enhanced magnetization processes create stronger and more stable magnetic fields.

Applications Leveraging Coreless Motors with Permanent Magnets

Coreless motors with permanent magnets are making a real impact across various industries, especially here in the U.S. Their lightweight and efficient design fits perfectly where precision and reliability matter most.

Medical Devices

- Used in micro pumps and precision instruments, these motors provide smooth and accurate control essential for medical procedures.

- Their low inertia and quick response help improve device performance without adding bulk.

Robotics and Automation

- Coreless motors boost robotic arms and automated systems by delivering high torque in a compact size.

- They allow fast and precise movements, enhancing productivity and accuracy in manufacturing.

Consumer Electronics

- From drones to smart devices, permanent magnet coreless motors offer the high power density and efficiency needed for longer battery life and better performance.

- Their quiet operation also improves the user experience in gadgets like cameras and wearables.

Automotive Applications

- Electric vehicles and actuators rely on these motors for smooth, energy-efficient operation.

- Their thermal stability and reliability make them ideal for high-demand environments under the hood.

In each of these fields, combining coreless motor design with advanced permanent magnets offers the best balance of power, weight, and responsiveness. This makes them a top choice for U.S. companies focusing on cutting-edge, reliable products.

Why Choose NBAEM for Your Magnetic Material Needs

When it comes to permanent magnet materials for coreless motors, NBAEM stands out with solid expertise and reliable manufacturing capabilities. Here’s why NBAEM is a strong choice for businesses across the U.S. market:

Expertise and Manufacturing Strength

- Wide Range of Magnetic Materials: NBAEM offers top-quality NdFeB (Neodymium), SmCo (Samarium-Cobalt), and ferrite magnets, covering all coreless motor requirements.

- Advanced Production Processes: From magnet shaping to coating and magnetization, NBAEM ensures consistent quality and performance.

- Custom Solutions: Tailored magnet designs to fit specific motor designs, improving efficiency and minimizing waste.

Commitment to Innovation and Quality

- Cutting-Edge R&D: NBAEM invests in developing rare-earth-free options and enhancing thermal stability in magnets.

- Stringent Quality Control: Each batch undergoes rigorous testing to meet U.S. standards, ensuring reliability and durability.

- Local Support: Responsive customer service with quick turnaround times to meet tight project deadlines.

Competitive Advantages for U.S. Customers

| Feature | Benefit |

|---|---|

| Localized Logistics | Faster shipping and reduced costs |

| Customization Flexibility | Magnet solutions tailored to application needs |

| Consistent Quality | Improved motor performance and lifecycle |

| Cost-Effective Pricing | Competitive rates without sacrificing quality |

| Technical Support | Expert advice for motor design optimization |

Many U.S. businesses, from medical device manufacturers to automotive companies, have enhanced their coreless motors by partnering with NBAEM. Their combination of quality, innovation, and customer focus helps drive better motor efficiency and reliability across applications.

Leave A Comment