Project Description

Construction Magnets

Precast Concrete is considered as the latest generation of commercial building material which gradually replacing traditional site-cast concrete in recent years. Precast concrete has been widely by the construction industry owing to its flexibility, durability, and economic efficiency. As an indispensable accessory of precast concrete system, precast concrete magnets are utilized to fix different embedded parts during pouring process of concrete. Precast concrete magnet can be further classified into shuttering magnet, insert magnet and magnetic chamfer according to their specific usage scenario.

Advantages of Construction Magnets (Precast Concrete Magnets)

- Labor and material cost will substantially reduce, and installation efficiency will be also enhanced in the meanwhile.

- Very easy and precise positioning.

- The positioning stage is free of screw, bolt, and welding, then stainless-steel plate can avoid damage.

- Reuse can be achieved. Thus keep long service time and shorter payback.

- Environment of the construction site will be strongly enhanced and simultaneously ensure safety of construction personnel.

Shuttering Magnets

Shuttering Magnet for Precast Formwork Introduction.

Precast concrete magnets are very popular in modern civil engineering. In the past 5 years, some conventional magnets were used to position and fasten the formwork, but considerable

mechanical loads with a hammer were required, which destroy the surface of the expensive

formwork tables and fragile neodymium magnet as well.

In order to facilitate the precast concrete formwork industry, NBAEM is developing and manufacturing our own shuttering magnet to solve this problem successfully.

Our shuttering magnet also is known as button magnets and magnetic boxes. It is consists of a metal casing, a magnetic system, and an effective on/off button, which provides quick operation leading to improved efficiency when setting out and remove the formwork. And with customized adaptors, shuttering magnet provides an ideal solution for almost all kinds of precast concrete formwork structures and construction for wood, aluminum, and steel shutters.

The NBAEM shuttering magnet have an automatic system to activate and deactivate the magnetic field. By application of this precast magnet box, the working time and cost will be reduced and the same workers could produce more concrete walls in a shorter time. Under the same artificial conditions, the use of the shutter magnet system can increase the production capacity by 7 times

Key Benefits Of Shuttering Magnets:

1.Easy installation and effortless operation. Your workers could choose a fixed position at will and quickly build concrete formwork according to individual architectural design. Significantly save complexity and time and cost on the installation of magnetic formwork (up to 70%).

2. Universal use for mass production of concrete products, and piece different shape and size concrete elements of all forms on the same steel table. Excellent applicability, the same prefabricated formwork magnet can be adapted to different concrete formworks. You do not need to have a lot of different forms for different products. The same magnet can be used for different purposes and in different ways. You only need a set of magnets, adapters for different height boards, and a steel table. Your workers could contemporaneously build different concrete formworks at one time; even during the building process, your workers could adjust the concrete formwork.

3. Integrated threaded holes M12 and M16 to adapt formwork and customized adapters, to fix all kinds of side-formwork including wood, steel, and aluminum formworks, eliminates the need for welding, shuttering magnets does not damage the steel table. Avoid welding or bolting to the formwork table therefore preserving surface finish and reduce direct damage to the concrete platform in the working.

4.No welding process is required, and the magnetic force of the magnet can be used to fit the template. Avoid welding or bolting to the formwork table therefore preserving the surface finish. No need for electric welding, you can save high energy consumption.

5.10-Year-long service life and reusable, low cost, short payback period.

Structure and Elements of Shuttering Magnets:

The Shuttering magnet assembly consists of steel Casing and fixing screws and a switchable magnetic block or magnetic core (certain designed magnetic circuit) which is made of some strong neodymium magnets and steel plates.

This magnetic core provides very much strong adhesive force to the precast concrete tables. There is a control ON/OFF button on the top of the shuttering magnet, to open or close the magnetic power.

Insert Magnets

NBAEM Insert Magnets, also called embedded magnet .

NBAEM insert magnets series are designed and developed for various embedded parts of precast concrete. During the precast concrete production process, we need to embed various switch holes, pile holes, and connection or lifting sockets.

Using our insert magnets to fix the embedded parts, magnets secure the parts against sliding and slipping. Our product is durable, cost-saving, easy-to-use, and efficient.

Insert Magnet for PVC Sealing Section

This insert magnet is designed to fix the sealing section when we produce the precast concrete.

This item can be used for a long time and works easily, so we can save costs during making the wall panels. Once it is positioned, it stands tightly, no-slip, as with much strong adhesive force onto the platform.

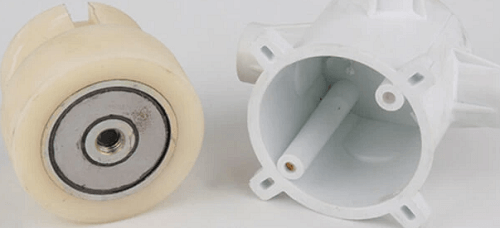

We have the size D150, D110, D75, D45, etc, we can see in the middle of the product is a screw, it is circled by thick nylon, of course, all the products accept customized, each customer have different kinds of requirement, we will do our best to reach your demand.

Circular Wire Box Insert Magnet

The insert magnet for the circular wire box is designed to leave the wire box hole when making precast concrete components. This embedded magnet is made of hard nylon and good quality magnet. Nylon rods are used for processing and forming, which can be flexibly customized according to customer needs, and used with powerful magnets to make the components more beautiful.

It is the settled shape and size, therefore, your demand must custom it, it is easy for us no matter drawing or sample because we are good at the magnet field design and make it true.

Insert Magnets with an external thread is designed for fixing embedded threaded bushing in precast concrete production.

Our products reach the standard, and according to your demand, we can match the thread, including M10, M12, M14, M16, M18, etc. all of the thread will be used the good quality steel, you can check the quality that providing you free samples.

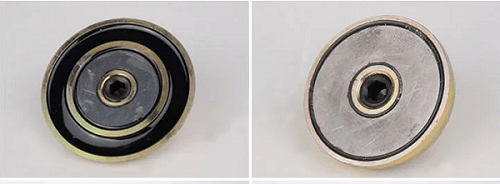

At the bottom of the insert magnet, you can find the black glue, it is made the circle shape and tightly connected, so the magnet that in the middle of the body can keep catching up the metal body, all the metal body, and magnet surface will keep clean and no scratch, it is our products Consistent standard, so you do not worry, you can try to contact us even if as a reference supplier, we will do our best to service for you, welcome to visit our factory, and showroom will be opened any time.

Magnetic Chamfer

What is Magnetic Chamfer?

The Steel Chamfer is one of the most useful and frequent accessories in the Precast Concrete industry.

Magnetic Chamfer is widely used for the attachment to steel shuttering surfaces and steel tables, for the purpose of:

·Quick and clean formation of chamfers, beveled edges, drip molds, dummy joints, and notches and reveal on the corners and faces of concrete wall panels and some formwork’s corner.

·Prevent the concrete overflow from the gap between the precast concrete casting table and side-formwork.

·And avoid the screwing or welding on the table or on the formwork. And it finally improves the precast concrete elements’ production times and labor costs.

Magnetic Chamfer Features:

1. High Quality, Reusable, durable for more than 3 years at least service life, ensure a nice payback on the original investment. Save money.

2. Powerful magnets are embedded at the surface of the chamfer to provide maximum adhesion to any steel surface. For example, single side magnetic steel chamfer offers more than 100KG per meter strength. It won’t be pulled out under normal use.

3. Rubber magnetic chamfer, both sides magnetized, and Steel Magnetic chamfer available in single-side magnetized (50% magnet) or both-side magnetized (100% magnet).

4. Easy to operate, quick to position, remove, and clean, quick, and accurate positioning exact beveled chamfers on the construction steel formwork table, and shortening the production timeline.

5. No open grooves to fill with the concrete. Securely, no screws, bolts, or welding are necessary, therefore preserving surface finish to increase the lifetime

6. Both magnetic trapezoidal and triangular chamfer strips available for clean chamfers and joints.

According to the material of the product, magnetic chamfer can be divided into three types:

1. Rubber Magnetic Chamfer (Most Flexible)

2. Steel Magnetic Chamfer (Strongest), is made of C1018 cold rolled steel and strong neodymium magnet fitted inserted and sealed with epoxy material to ensure no damage from concrete or maximum reuse.

3. Polystyrene neodymium magnetic chamfer (flexible and strong)

According to the cross-section shape of the product, magnetic chamfer can also be divided into three types:

1. Triangle magnetic chamfer

2. Trapezoid Magnetic Chamfer

3. Special shape magnetic chamfer (according to customer’s request)

Magnetic Chamfer Application

Magnetic chamfers are often used in the manufacture of concrete products, working with steel beds or steel faceplates and bulkheads that can be mounted to most types of precast rail-frame systems on the market.

The magnetic chamfer is required for the formation of the chamfered corner on the product in order to create an accurate aesthetic appearance of the corners of concrete products, and also eliminates bevel angles of concrete products from chipping.

REQUEST A QUOTE

Looking for a certain size? Please see the different sizes of magnets as follows. If you require a specific size that is not available on our website, please contact us for a custom neodymium magnet quote.