Project Description

NBAEM Magnet Assembly

Magnetic assemblies are equipped with permanent magnets like NdFeB magnets and other material parts like metal, stainless steel, plastic, rubber, adhesive tape, wood, hardboard and etc. Magnet assemblies can be much more powerful than magnet itself, and achieve some certain functional effect which magnet cannot meet.

From permanent magnets to large complex magne assemblies, has a legacy of designing, manufacturing and delivering systems to meet the needs of our partners and their application requirements.

Here are the typical applications of Magnet Assembly. You can click them to learn more information. We keep hundreds of thousands of standard magnet assemblies in stock. We also make custom assemblies to serve any new application you come up with. Magnetic motor assemblies, pot magnets, magnetic latches, electromagnets, pot magnets, precast concrete magnets, bullet magnet, magnetic filter, magnetic liquid traps and magnetic tools are also available to meet your project requirements.

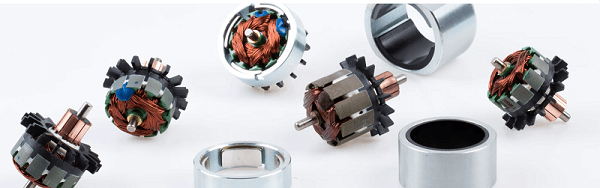

1. Magnetic Motor Assemblies

NBAEM automates rotor and stator production. A permanent magnet motor consists of two basic parts: a stator coil and a rotor. A stator coil which is powered by an alternating current, creates an electric filed. A rotor made of permanent magnets rotates within that field. An AC motor that uses magnets is imbedded into or attached to the surface of the motor’s rotor.

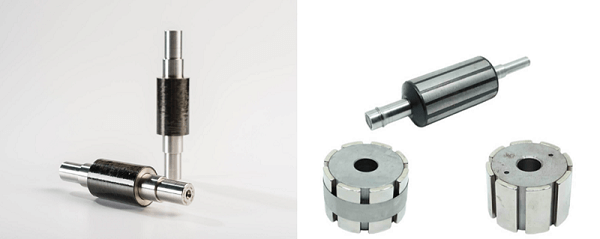

Magnetic Rotor Assemblies

Magnetic rotor or permanent magnet rotor is the non-stationary part of a motor. As one of the most representative magnetic assemblies, rotor assemblies are consisting of iron part and permanent magnet. Sintered Neodymium magnet, sintered Samarium Cobalt magnet, bonded magnet and ferrite magnet are all can be utilized to rotor assemblies according to different application, motor type and assembly process. It should be pointed out that laminated magnets made by magnet segmentation technology are also served to assemblies to decrease the eddy current loss.

The rotor is the moving part in an electric motor, generator and more. Magnetic rotors are designed with multiple poles. Each pole alternates in polarity (north & south). Opposite poles rotate about a central point or axis (basically, a shaft is located in the middle). This is the principal design for rotors. It is used in the In-wheel motor of electric sport car. NBAEM offers high performance permanent magnet motor components and sub-assemblies for aerospace and defense, industrial, automotive, and motorsport applications.

Magnetic Stator Assemblies

Magnetic stator assemblies are consisting of housing and permanent magnet which similar like magnetic rotor assemblies. Permanent magnets are mounted on the housing, then housing working as the magnetic yoke to a form a magnetic circuit. Besides conventional magnetic stator assemblies which used sintered Neodymium magnet, bonded magnet, and the ferrite magnet, NBAEM is also able to provide linear motor stator assemblies and latest axial flux motor assemblies to our valued customers

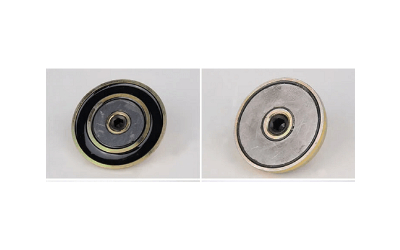

2. Pot Magnet Assemblies

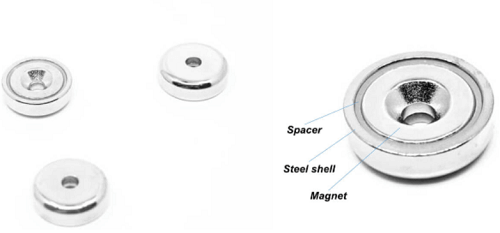

POT Magnetic assemblies are aimed at prevent brittle magnet to crack and significantly improve magnetic strength. Pot magnets are the outstanding representative which embodies these two advantages. The structure of conventional pot magnets consists of the permanent magnet, steel shell, and spacer. Sintered Neodymium magnets, sintered Samarium Cobalt magnets, ferrite magnets and AlNiCo magnets are all can be served in the pot magnets.

Pot magnets consist of a steel shell with a magnet sunken into one face, which design gives many advantages; which can be supplied with a countersunk hole, a straight hole, a threaded stud, or a threaded collar or a screw hole. The main Magnetism is confined to one face, where it is concentrated to give the maximum holding force possible for the size of the magnet. Pot magnets are resistant and don’t crack or chip with constant impacting onto a steel surface which is a very big advantage.

And they can be provided with hooks and eyebolt attachments, which are perfect for hanging a variety of items.

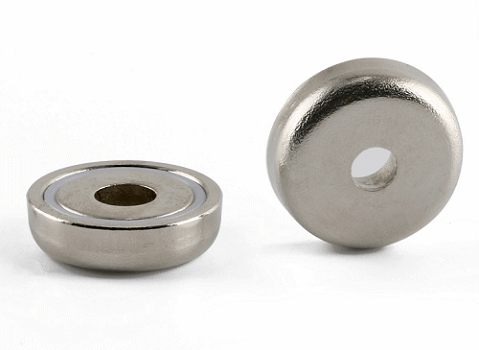

Neodymium pot magnets

The neodymium pot magnet can be with countersunk hole, straight hole, external Thread, internal thread and many other different designs.

Neodymium Pot Magnet with External Thread

This type of male thread strong neodymium pot magnet named neodymium male cup magnet too. As they are have a male threaded stud which can be put through a hole on the wall or mounted into wooden, or fastened with a gasket and nut. They widely used for trade fair, any shop build or other purpose. No matter use in private household or commercial or hobby applications are all suitable.

Neodymium Pot Magnet with Internal Thread

These magnets have a female thread hole, can for M3,M4,M5,M6,M8 M10 or customized. They need to fasten with a male thread. As the metal pot to change the magnetic flux to make the force become strong, so even with a small size, but the force is very strong. They are suitable for strong and quickly removable fasten no need drilling. They are widely used for trade fair, any shop build or other purpose. No matter use in private household or commercial or hobby applications are all suitable.

Neodymium Pot Magnet with straight hole

This straight hole pot neodymium magnet have not big special different than countersunk hole type, it just different on hole, and use bolt instead of screw. They can be coating with ZN,NICUNI or Black epoxy. To choice what coating it is basis your application environment, the black epoxy have great anti-corrosion ability, but price higher than ZN and NICUNI. Please contact us to get the quote.

Neodymium Pot Magnet with countersunk hole

This pot magnet with a countersunk hole, can easy use screw to mount on the wall, celling or your other application. Normally the hole can with M3,M4,M5,M6,M8 or as your request type of screw to custom. We have many kinds of molds for you to choose.

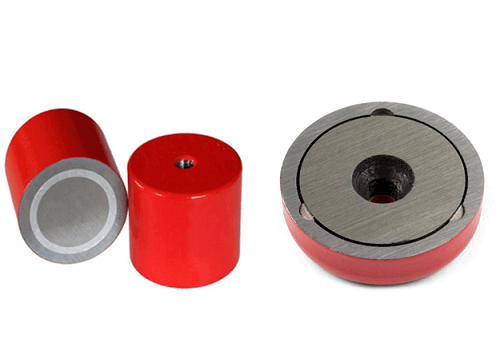

AlNiCo pot magnets

Alnico deep pot magnet are very popular in clamping applications because you can simply bolt them onto your assembly. The larger units provide very powerful clamping forces, with the mild steel outer cup providing protection and mechanical strength to the pot magnet and inner magnet. Because the mild steel is threaded, reasonably high torque can be applied to securely hold the pot magnet in place.

The countersunk mounting pot magnet / shallow pot magnet is a ferromagnetic steel cup into which is inserted a countersunk ring magnet. There is a hole all the way through the countersunk mounting pot magnet / shallow pot magnet. This allows a screw head to be inserted into the countersunk mounting pot magnet / shallow pot magnet to screw the countersunk mounting pot magnet / shallow pot magnet to any material of your choice to give a good mechanical hold.

Ferrite pot magnets

Ferrite pot magnets, also called Cup Magnets, Magnetic Holders, are made of permanent magnet encased in a metal pot, and feature a hole, thread, boss or removable hook in centre of the magnets. The pot is an essential part of the magnetic circuit. the active magnet face is not enclosed. When Pot magnets hold any metal parts, the magnetic force in this circuit is stronger than that of alone magnet. It is the most efficient design for gripping, also provide an easy, non-destructive way to suspend objects or attach them to metal.

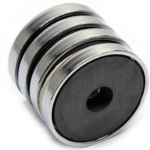

Samarium cobalt pot magnets

*Permanent magnetic pot magnets with Samarium Cobalt system.

*Powerful with a focused magnetic field

*Construction: Samarium Cobalt+Iron component+brass component

*Versions up to 200° on request

Rubber coated pot magnets

Rubber coated pot magnets are high in magnetic strength and weatherproof so they are ideal for indoor and outdoor applications where high magnetic strength is required, and have a superior slide resistance over regular magnets due to the increased friction generated between a rubber and smooth steel surface. By adding a rubber-coating to increase its resistance to corrosion

and safe to use on easily marked surfaces without scratching. They are frequently used for holding, mounting and fixing purposes, include suspending outdoor cameras, hanging signage and mounting sensors, lights or fixtures to equipment repair, holding tools and organizing items in warehouses, workstations and other outdoor areas. It also has screwed bush, internal thread, external thread and other different kind of types.

3. Magnetic Separator Assemblies

Magnetic separation contains simple permanent magnetic separation technology and the eddy current separation technology. The conventional permanent magnetic separators rely on magneto-static force to recovery ferromagnetic metal from ferromagnetic/non-ferromagnetic mixture, and widely used to mineral separation, garbage disposal and food industry. Eddy current separation recovery non-ferromagnetic metal from garbage through current magnetization. Permanent magnetic separators are always occupying a large proportion in permanent magnet markets.

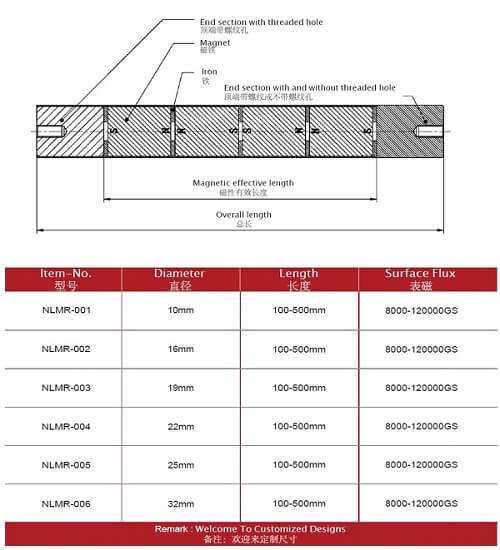

Magnetic Bar tech data

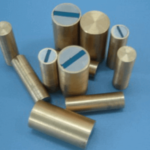

Magnetic Bar

Magnetic Filter Bar is consisted of stainless steel tube and strong NdFeB magnet. They can effectively remove ferrous chips and metal particles from free flowing materials.

Technical Data:

*The standard diameter we supply is D10, D19, D20, D25, D25.4, D32, D50.8 and etc. The size can be varied at your request

*Magnetic filter bar is usually made of seamed or seamless 304 stainless steel tubes or 316 stainless steel tubes. The tubes can be fine polished and fully welded to meet food grade or pharmacy application.

*Standard working temperature is 80℃, but we can offer up to 350℃ to meet your special applications.

*By using different grade of rare earth magnets, different magnetic force are available to meet every customer’s requirement, the highest magnetic force of diameter 25mm magnetic bar can achieve 12,000GS(1.2T).

*3000-5000 pieces magnetic filter bars, which is hard to be finished by other factories using argon arc welding, can be welded in one day by our laser welding.

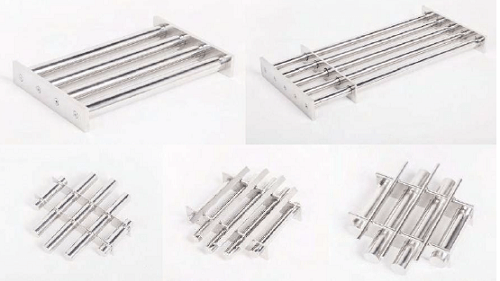

Magnet Grate

NBAEM Magnetics standard diameter of grate magnet bar is D25mm.

Mainly two shapes of Grate Magnet: round shape and square shape, provide with many varied sizes for your choice. Single layer or multi-layers can be designed per your request.

It has excellent performance with no leak, anti- corrosion and long working life.

Easy-clean type can be provided on request.

All the magnetic bars are waterproof.

Surface: Well-polished.

Drawer magnet

Drawer Magnets remove small-to-medium sized metal impurities from dry free-flowing material. They are widely used in fields of ceramics, chemicals, pharmacy, food, plastic, rubber, dyestuff, mining, environmental protection and etc. Two models of magnetic drawers are available: Circle- shape and Square-shape.

Commercial Magnetic Filter

Commercial Magnetic Filter is used to remove ferrous particles and other micro contamination. In order to adapt to different working conditions, NBAEM has developed different types of fluid separator.

- The surface gauss could be chosen from 8000~12000GS.

- Removes both magnetic and non-magnetic contamination – optional mesh strainer

- The standard operating temperature ≤80℃. If need, the maximum working temperature is able to be up to 350℃.

- Use flanges clamps, bolts plate, quick release clip or other designs, magnetic parts could be easily installed, removed and cleaned up.

- Material could be 304 or 316 stainless steel.

- Reasonable structural design to ensure the best results, meanwhile high flow capability won’t be influenced.

- Pressure requirements or other special requirements, could be satisfied according to customer requirements.

4. Magnetic tools

Magnet is wildly used in our life and work. There are different kinds of magnetic tools with attractive design .You can find the total solution for any housewares, home , automotive, office, industry, promotion and so on. Here are some examples . Please feel free to contract us for more design.

Magnetic name plate

Magnetic name plate, we can also call it magnetic name badge, magnetic badge fastener, magnetic badge holder, are an instant introduction which tells a stranger who you are and where department you work, and magnetic name badges are perhaps the most convenient one compared to traditional name badges. The powerful magnet can hold the magnetic name badge on the shirt.

Magnetic plate

Magnetic Plate can be used in various kinds of processes. They are usually installed above transfer conveyors and vibratory feeders to attract “tramp” type ferrous contamination and any loose machinery that has fallen off during the manufacturing and packaging stages. The magnetic plate consists of two rows of magnetic material running the full length of the plate.

Magnetic Sweeper

NBAEM magnetic sweeper is ideal for quick and easy picking up hardware, scraps and other metal parts over floors, carpet and even grass. A new kind of magnetic sweeper has also been developed for trapping iron sludge and ferrous muds in water tanks. We can offer different designs of magnetic sweeper.

Fishing magnets

People had been having fun of treasure hunting long ago and now many people from all age groups are turning treasure hunting as an enjoyable hobby. As one of the treasures hunts, magnet fishing is not the magnetic fishing toys what most people might think. Magnet fishing is about finding ferromagnetic objects in outdoor water by extremely strong fishing magnets which quite like utilize the metal detector to find objects on land.

5. Precast Concrete Magnets

Precast Concrete is considered as the latest generation of commercial building material which gradually replacing traditional site-cast concrete in recent years. Precast concrete has been widely by the construction industry owing to its flexibility, durability, and economic efficiency. As an indispensable accessory of precast concrete system, precast concrete magnets are utilized to fix different embedded parts during pouring process of concrete. Precast concrete magnet can be further classified into shuttering magnet, insert magnet and magnetic chamfer according to their specific usage scenario

Advantages of Precast Concrete Magnets

- Labor and material cost will substantially reduce, and installation efficiency will be also enhanced in the meanwhile.

- Very easy and precise positioning.

- The positioning stage is free of screw, bolt, and welding, then stainless-steel plate can avoid damage.

- Reuse can be achieved. Thus keep long service time and shorter payback.

- Environment of the construction site will be strongly enhanced and simultaneously ensure safety of construction personnel.

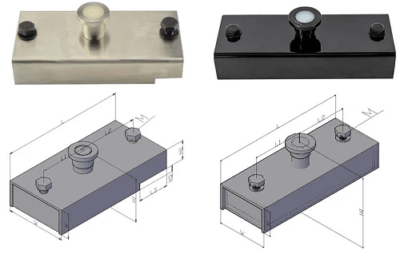

Shuttering Magnets

Shuttering Magnet for Precast Formwork Introduction.

Precast concrete magnets are very popular in modern civil engineering. In the past 5 years, some conventional magnets were used to position and fasten the formwork, but considerable

mechanical loads with a hammer were required, which destroy the surface of the expensive formwork tables and fragile neodymium magnet as well.

In order to facilitate the precast concrete formwork industry, NBAEM is developing and manufacturing our own shuttering magnet to solve this problem successfully.

Our shuttering magnet also is known as button magnets and magnetic boxes. It is consists of a metal casing, a magnetic system, and an effective on/off button, which provides quick operation leading to improved efficiency when setting out and remove the formwork. And with customized adaptors, shuttering magnet provides an ideal solution for almost all kinds of precast concrete formwork structures and construction for wood, aluminum, and steel shutters.

The NBAEM shuttering magnet have an automatic system to activate and deactivate the magnetic field. By application of this precast magnet box, the working time and cost will be reduced and the same workers could produce more concrete walls in a shorter time. Under the same artificial conditions, the use of the shutter magnet system can increase the production capacity by 7 times

Insert Magnets

NBAEM Insert Magnets, also called embedded magnet .

NBAEM insert magnets series are designed and developed for various embedded parts of precast concrete. During the precast concrete production process, we need to embed various switch holes, pile holes, and connection or lifting sockets.

Using our insert magnets to fix the embedded parts, magnets secure the parts against sliding and slipping. Our product is durable, cost-saving, easy-to-use, and efficient.

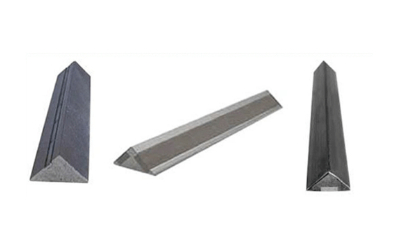

Magnetic Chamfer

The Steel Chamfer is one of the most useful and frequent accessories in the Precast Concrete industry.

Magnetic Chamfer is widely used for the attachment to steel shuttering surfaces and steel tables, for the purpose of:

·Quick and clean formation of chamfers, beveled edges, drip molds, dummy joints, and notches and reveal on the corners and faces of concrete wall panels and some formwork’s corner.

·Prevent the concrete overflow from the gap between the precast concrete casting table and side-formwork.

·And avoid the screwing or welding on the table or on the formwork. And it finally improves the precast concrete elements’ production times and labor costs.

Insert Magnets

NBAEM Insert Magnets, also called embedded magnet .

NBAEM insert magnets series are designed and developed for various embedded parts of precast concrete. During the precast concrete production process, we need to embed various switch holes, pile holes, and connection or lifting sockets.

Using our insert magnets to fix the embedded parts, magnets secure the parts against sliding and slipping. Our product is durable, cost-saving, easy-to-use, and efficient.

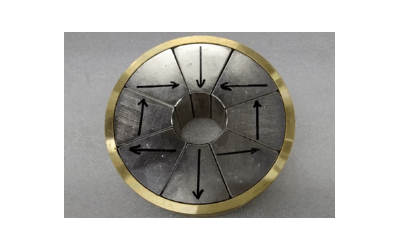

6. Halbach array

A Halbach Array is a special arrangement of permanent magnets that makes the magnetic field on one side of the array stronger, while canceling the field to near zero on the other side. Halbach array magnets for sale are very different from the magnetic field around a single magnet. With a single magnet, you have an equal strength magnetic field on either side of the magnet.

Applications of Halbach Arrays

- Halbach Array is most commonly used to produce a magnetic field utilizing permanent magnets arranged in a 90° orientation change between magnetic elements, which amplifies the magnetic force.

- Planer Halbach Arrays are typically used for holdings, fixturing, linear coupling applications, etc.

- Circular Halbach Arrays (OD iteration) can be used in rotors for brushless DC motors, magnetic couples, power generations, etc.

- Circular Halbach Arrays (ID iteration) are used to constrain plasma, steer, sort and accelerate moving charged particles, and impart oscillations.

Where are Halbach Arrays actually Used?

Halbach Array is most commonly used to produce a magnetic field utilizing permanent magnets arranged in a 90° orientation change between magnetic elements, which amplifies the magnetic force.

Halbach Arrays can also be configured in other shapes. A halbach array ring magnet with multi-pole magnetization or a ring made up of smaller arc segments can be used in this way.

CONTACT TO GET PRICE OR SAMPLES!