Project Description

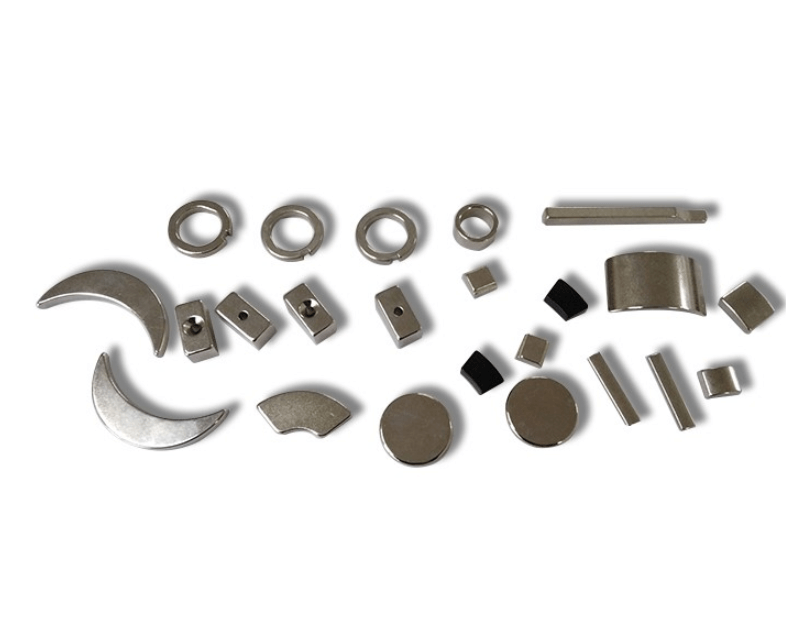

STRONG Neodymium magnet

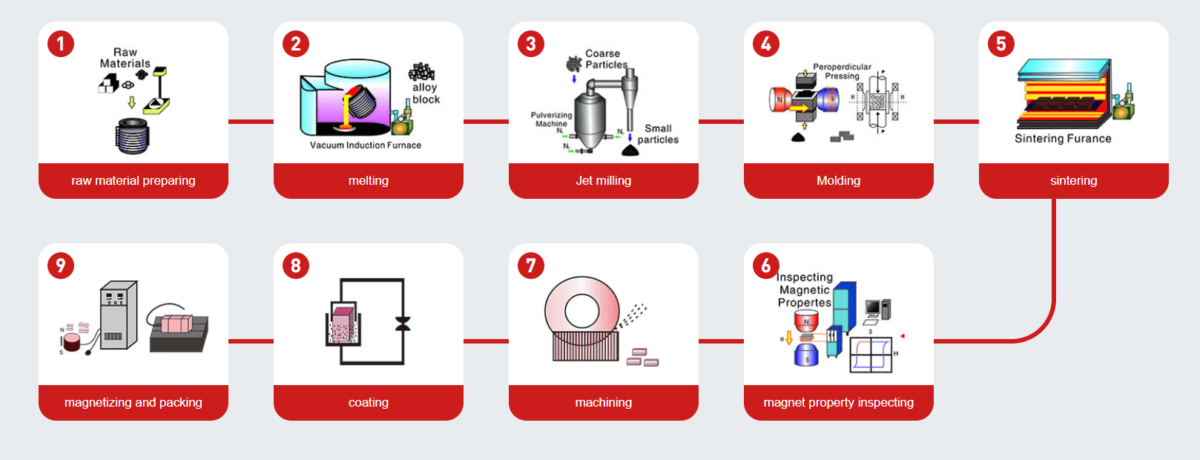

Strong neodymium magnets also known as NdFeB, NIB, or Neo magnets, are the most widely-used type of rare-earth magnets. It is the strongest type of permanent magnet material made from an alloy of Neodymium, Iron, and Boron with the Nd2Fe14B tetragonal crystalline structure, developed independently in 1984 by General Motors and Sumitomo Special Metals.

NdFeB magnet has replaced other types of magnets in many applications in modern products that require strong permanent magnets. They are widely used in many areas, such as motors in cordless tools, hard disk drives, magnetic fasteners, electric motors, sensors, speakers, rotors, alarm, microphones, wind turbines/wind generators, magnetic hooks, magnetic holders, filters automobiles and so on. Low weight loss magnet , Low-temperature coefficient magnet, low deviation angle magnet, and radial oriented ring magnet are our featured products.

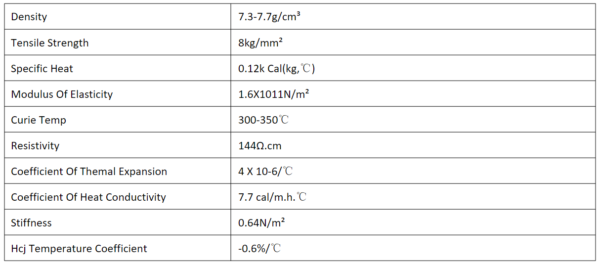

Neodymium Magnet Physical Properties

Neodymium Magnet Applications

Neodymium magnets have replaced alnico and ferrite magnets in many of the applications in modern technology where strong permanent magnets are required, because their greater strength allows the use of smaller, lighter magnets for a given application. Some examples are:

- Motors and Generators

- Automotive (clamps, sensors)

- Aerospace

- Separation (rods, grids, etc) – 10-12kG (22-26lbs) systems

- High performance magnetic clamps and pot magnets

- Computer hard drives

- Consumer electronics

- High-end speakers.

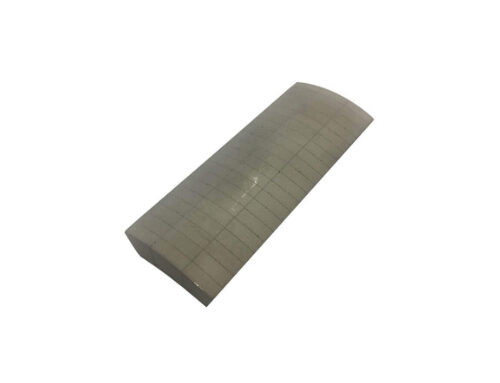

Neodymium arc magnets

As the third generation of rare earth permanent magnet, Neo magnets are the most powerful commercially produced magnets. Neodymium arc magnets, also known as Neodymium segment magnets, are common shape of Neo magnet, then almost all of neodymium arc magnets are utilized by permanent magnet motors, generators, and coupling devices. Neodymium arc magnets are always machined by wire cutting or grinding process.

- Dimensions: According to your requirements

- Grade: N35~N55 (M,H,SH,UH,EH,AH)

- Max Operating Temperature: 60~220 degree celsius

- Coating: Zn, NiCuNi, Epoxy, Sn, Gold, everlube, parylene, Phosphating, etc.

- Direction of Magnetization: Diametrical , thickness, width

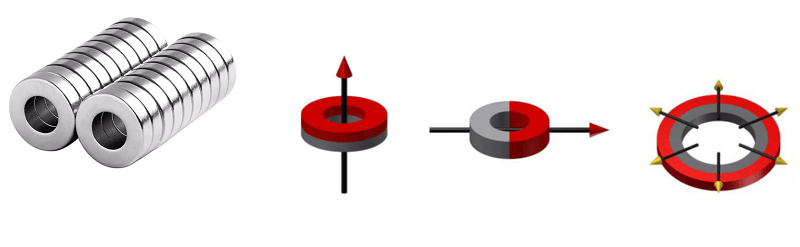

Neodymium ring magnets

Neodymium ring magnets are circular in shape with a hollow center. Besides the conventional axial magnetized or diametrically magnetized ring magnets, radially oriented ring magnets are also available in NBAEM. Neodymium ring magnets are easy to be corrosion under humid environment and is necessary to covered with a protective coating.

Neodymium ring magnets are the popular shape of neodymium Rare earth magnets. They are manufactured via cutting, slicing, drilling, and grinding etc. They are widely used in loudspeakers, sensors, and perfume cap,etc.

- Dimensions: According to your requirements

- Grade: N35~N55 (M,H,SH,UH,EH,AH)

- Max Operating Temperature: 60~220 degree celsius

- Coating: Zn, NiCuNi, Epoxy, Sn, Gold, everlube, parylene, Phosphating, etc.

- Direction of Magnetization: axial, diametrical , multi-Poles or radial

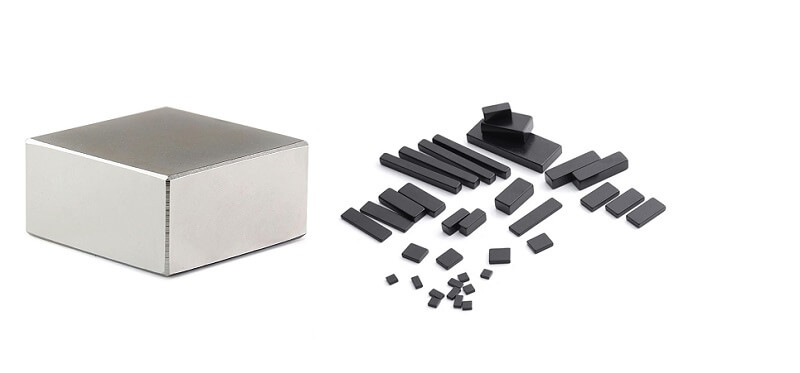

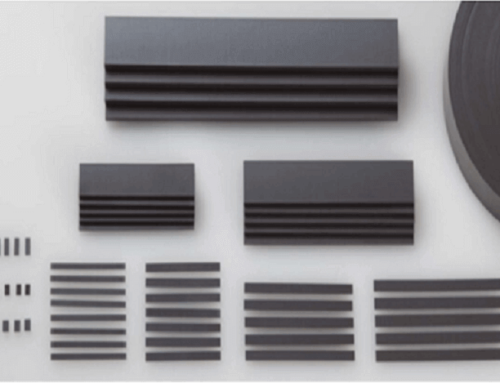

Neodymium block magnets

Neodymium square magnet / rectangle magnet / block magnet are available in a wide range of grades, dimensions, and coatings. Operating temperatures of Neodymium block magnets vary among material’s grades and can be used for a huge variety of applications.

- Dimensions: According to your requirements

- Grade: N35~N55 (M,H,SH,UH,EH,AH)

- Max Operating Temperature: 60~220 degree celsius

- Coating: Coating: Zn, NiCuNi, Epoxy, Sn, Gold, everlube, parylene, Phosphating, etc.

- Direction of Magnetization: width ,length, thickness

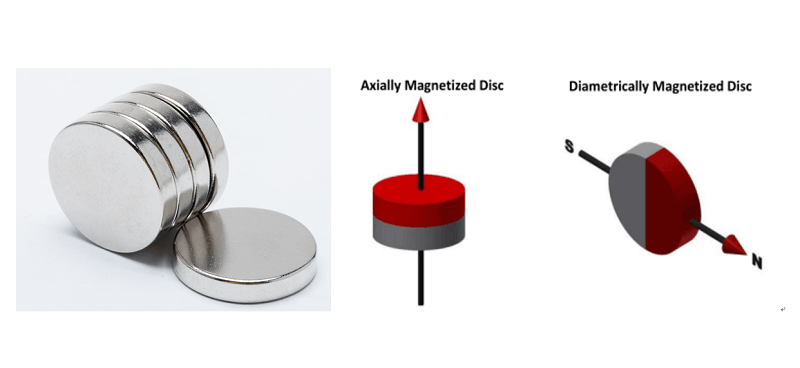

Neodymium disc/round magnets

Neodymium disc magnets or round magnets have become a preferred solution for a wide variety of applications. Neodymium disc magnets are widely served for both industrial and civil applications. Production efficiency of neodymium disc magnets has gained a great development with the widely application of multi-wire sawing.

- Dimensions: According to your requirements

- Grade: N35~N55 (M,H,SH,UH,EH,AH)

- Max Operating Temperature: 60~220 degree celsius

- Coating: Zn, NiCuNi, Epoxy, Sn, Gold, everlube, parylene, Phosphating, etc.

- Direction of Magnetization: axial, diametrical or multi-Poles

Neodymium irregular magnets

Special shaped magnets refer specially to the magnets with irregular shape which primarily serve for specific demands. Injection molded magnets are ideally suited for special shaped magnets, but maximum energy product (BH)max of routine isotropic injection NdFeB molded magnets are limited to 60kJ/m3 which cannot satisfy most of special shaped demands. Sintered magnets are generally difficult to achieve net shape at once due to technology limitations in molding and sintering process, thus machining process is essentially impossible to be avoided. Therefore, sintered neodymium magnets are always criticized by its machinability, but special shaped NdFeB magnets still can be obtained via grinding or wire cutting process, hence its cost and production time are inevitability and significantly higher than conventional block magnets, bar magnets, ring magnets, disc magnets, rod magnets, arc magnets, countersunk magnets, and sphere magnets. Chinese Neodymium magnets industry has already formed a clear division of labor over the years, thus processing enterprises fully learned processing experience from crystal industry and always trying to introduce the latest processing technology. With the process of functional complexity and miniaturization accelerates, consumer electronics exist large demand for special shaped Neodymium magnets.

- Dimensions: According to your requirements

- Grade: N35~N55 (M,H,SH,UH,EH,AH)

- Max Operating Temperature: 60~220 degree celsius

- Coating: Zn, NiCuNi, Epoxy, Sn, Gold, everlube, parylene, Phosphating, etc.

- Direction of Magnetization: According to your requirements

REQUEST A QUOTE

Looking for a certain size? Please see the different sizes of magnets as follows. If you require a specific size that is not available on our website, please contact us for a custom neodymium magnet quote.