Selecting the right ímã permanente isn’t just a design choice—it’s the deciding factor between a high-efficiency powerhouse and a motor that fails under pressure. Whether you are engineering motores de tração de veículos elétricos or precision robotics, the magnetic material you choose dictates your torque density, thermal limits, and bottom line.

In the world of permanent magnet motors, there is no “one size fits all.” From the sheer strength of Neodímio (NdFeB) to the rugged thermal stability of Cobalto de Samário (SmCo), each material offers a different competitive edge.

Are you looking to maximize performance or minimize costs? I’ve broken down the technical specifications and real-world applications of the industry’s most critical motor magnets to help you make the right call.

motor magnets

Let’s dive right in.

The Best Magnet Types for Your Motor Project

Picking the right magnet isn’t just a technical detail; it’s the heartbeat of your motor’s efficiency. I’ve seen how the wrong choice can lead to demagnetization or unnecessary costs. Here are the four primary rare earth motor magnets and traditional materials I rely on to get the job done.

Neodymium Iron Boron (NdFeB) for Peak Performance

When I need maximum torque in a compact space, Ímãs permanentes NdFeB are my first choice. They offer the highest energy product of any material, making them the industry standard for EV traction motor magnets.

- Maximum Power: Unmatched magnetic flux density.

- Space Saving: High energy density allows for smaller, lighter motors.

- Versatilidade: Available in various magnet grades for PM motors (from N to AH).

- Constraint: Requires protective coatings to prevent corrosion.

Samarium Cobalt (SmCo) for Extreme Heat

For aerospace or high-performance industrial gear, heat is the enemy. Samarium cobalt in PM motors shines because it maintains its magnetic field at temperatures where Neodymium would fail.

- High Curie Temperature: Operates reliably up to 350°C.

- Resistência à Corrosão: Doesn’t need the heavy plating required by NdFeB.

- Stability: Excellent thermal stability for precision applications.

Cost-Effective Ferrite (Ceramic) Magnets

If I’m working on a project where the budget is tight and size isn’t the primary constraint—like household appliances—ferrite magnets for electric motors are the go-to.

- Low Cost: Most economical option for mass production.

- High Coercivity: Naturally resistant to demagnetization.

- Easy Sourcing: No rare-earth supply chain headaches.

Niche Alnico Magnets and Specialty Uses

While less common in modern high-speed motors, Alnico still has its place in specialized sensors and instruments.

- Temperature Ruggedness: Incredible stability across a wide temperature range.

- Low Coercivity: Easier to magnetize and demagnetize, which suits specific niche designs.

Motor Magnet Types Comparison

| Tipo de Ímã | Produto de Energia (MGOe) | Temp. Máx. de Operação | Resistência à Corrosão | Custo |

|---|---|---|---|---|

| NdFeB sinterizado | 33–52 | 80°C – 230°C | Low (Needs Coating) | Moderado |

| SmCo | 16–32 | 250°C – 350°C | Alto | Alto |

| Ferrita | 3.4–4.5 | 250°C | Alto | Very Low |

| Alnico | 5.0–9.0 | 450°C – 540°C | Alto | Moderado |

How I Choose the Right Magnet Used in Permanent Magnet Motors

When I select the magnet grades for PM motors, I look past raw power. I balance torque requirements against the environmental reality of the motor’s housing. It is a game of trade-offs between magnetic strength vs. temperature resistance. While Ímãs permanentes NdFeB offer the highest energy product, their performance can drop sharply if the Curie temperature motor magnets reach their limit. For heavy-duty industrial cycles, I often pivot to ímãs de alta temperatura that maintain stability under thermal stress.

Critical Selection Factors for Motor Efficiency

| Fator | Prioridade | Por que isso importa |

|---|---|---|

| Fluxo Magnético | Alto | Directly dictates motor torque and power density. |

| Coercivity ($H_{cj}$) | Alto | Prevents demagnetization in permanent magnets during peak loads. |

| Estabilidade Térmica | Medium/High | Essential for preventing power loss as the motor heats up. |

| Resistência à Corrosão | Médio | Vital for neodymium magnets for motors to avoid oxidation. |

- Managing Demagnetization Risks: I never ignore the “knee” of the demagnetization curve. If the motor draws too much current, the resulting counter-magnetic field can permanently weaken the rotor magnets. Choosing a high-coercivity grade is my insurance policy against this.

- Corrosion Resistance and Protective Coatings: Since sintered vs bonded motor magnets have different porosities, I specify coatings like Nickel-Copper-Nickel or Zinc for NdFeB. This prevents the “magnet pest” (oxidation) from destroying the rotor from the inside out.

- Dimensional Precision for Rotor Assembly: I demand tight tolerances. Even a fraction of a millimeter of error can ruin the air gap flux. Precision is non-negotiable for a successful conjunto de ímã where the magnets must fit perfectly into the rotor slots for high-speed stability.

- Balancing Cost and Performance: Not every project needs a Ferrari engine. For low-cost appliances, ferrite magnets electric motors are often the smartest choice because they provide adequate performance without the price volatility of rare earth elements.

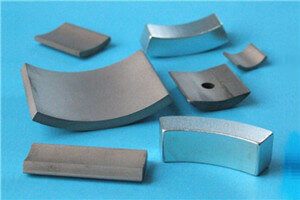

Common Magnet Shapes and Configurations

The physical shape of a magnet is just as important as its strength. When determining what magnet is used in permanent magnet motors, we look at how the geometry influences the magnetic circuit and overall torque.

Arc Segments, Tiles, and Radial Rings

For most motor builds, we use specific shapes to match the rotor’s curvature:

- Arc Segments: These “tile” shapes are the industry standard for high-performance rotors, allowing for a tight fit and minimal air gap.

- Radial Rings: Used primarily in precision brushless motors to provide a seamless, 360-degree magnetic field.

- Rectangular Blocks: Often found in larger, low-speed industrial motors where cost-efficiency is a priority.

Surface-Mounted (SPM) vs. Interior-Embedded (IPM)

How we position the magnet determines the motor’s top speed and durability.

- Surface Permanent Magnet (SPM): We glue the magnets directly onto the rotor surface. This is easier to manufacture and great for low-to-medium speed applications.

- Interior Permanent Magnet (IPM): We slide the magnets into slots inside the rotor laminations. This is the go-to for EV traction motor magnets because it protects the magnets from flying off at high RPMs and improves “reluctance torque.”

[Image comparing SPM and IPM rotor designs showing magnet placement]

How Geometry Changes Flux Distribution

The shape of the magnet dictates the flux distribution across the air gap. By using specialized arc segment magnets, we can create a sinusoidal magnetic field that reduces “cogging”—that annoying jerky movement in motors. Whether you are comparing ferrite vs neodymium or high-grade alloys, the way the magnet is cut directly impacts the motor’s smoothness and efficiency.

- Bread-loaf shapes help concentrate flux toward the center.

- Halbach arrays (using multiple shapes) can eliminate the need for a heavy back-iron by directing all magnetic force to one side.

Where We Use These Permanent Magnets

I see these components as the heart of modern machinery. Choosing what magnet used in permanent magnet motors depends entirely on the environment, but the impact is always the same: higher efficiency and smaller footprints.

EVs and Renewable Energy Systems

The shift to green energy relies heavily on EV traction motor magnets. Most high-performance electric vehicles use Ímãs permanentes NdFeB because they provide the massive torque and power density needed for long-range driving. As a leading neodymium magnet supplier, I ensure these materials meet the rigorous demands of both automotive drivetrains and wind turbine generators.

Automação Industrial e Robótica

In the world of factory floors, precision is the priority. I use high-grade neodymium magnets in servo motors to ensure lightning-fast response times and exact positioning.

- Robotic Arms: Require lightweight, high-flux magnets to reduce joint weight.

- CNC Machinery: Relies on stable magnetic fields for consistent machining accuracy.

- Conveyor Systems: Often utilize ferrite magnets electric motors when cost-efficiency is more critical than raw power.

High-Temp Aerospace and Medical Gear

In environments where failure isn’t an option, Samarium cobalt in PM motors is the standard. I specify these for aerospace actuators and medical pumps because they maintain their strength in extreme heat. Unlike standard options, these rare earth motor magnets won’t demagnetize when the temperature spikes during flight or high-intensity medical procedures.

Everyday Household Appliances

You’ll find what magnet used in permanent magnet motors varies based on your budget and the appliance’s goal.

- Washing Machines: Uso ímãs de ferrita for long-term durability and cost-effectiveness.

- Cordless Vacuums: Depend on high-RPM motors powered by sintered vs bonded motor magnets to maximize suction in a handheld frame.

- Air Conditioners: Use permanent magnet synchronous motors to achieve high energy-efficiency ratings.

Boosting Motor Performance Beyond the Magnet

Choosing the right magnet used in permanent magnet motors is the foundation, but the surrounding architecture determines if you actually hit your efficiency targets. I focus on optimizing the entire magnetic circuit to ensure the hardware doesn’t just run, but excels under load.

Using Lamination Cores to Cut Losses

Even the best Ímãs permanentes NdFeB can’t reach their potential if the motor core is fighting against them. We use thin, insulated silicon steel laminations to build the rotor and stator. This structure breaks up eddy currents, significantly reducing heat and energy waste. By managing these parasitic losses, we ensure that permanent magnet synchronous motor materials operate at peak efficiency without premature thermal degradation.

Advanced Halbach Arrays for Better Flux

For projects requiring extreme power density, like EV traction motor magnets, I often implement a Halbach array motor design. This specific geometric arrangement:

- Concentrates Magnetic Flux: Directs the field toward the stator while nearly cancelling it on the back side.

- Reduces Weight: Eliminates the need for heavy iron backing in many cases.

- Optimizes Performance: Provides a more sinusoidal field, which is critical for ímas usados em energia renovável systems and high-speed rotors.

Precision Manufacturing and Quality Standards

Consistency is the silent killer of motor performance. If the air gap between your arc segment magnets and the stator varies by even a fraction of a millimeter, you’ll deal with torque ripple and noise. We maintain strict manufacturing standards to ensure every component fits perfectly:

- Dimensional Accuracy: Ensuring the rotor balance is perfect to prevent vibration at high RPMs.

- Grade Verification: Testing magnet grades for PM motors to ensure they meet the specific coercivity and remanence requirements for the application.

- Adhesion Integrity: Using high-strength, temperature-resistant adhesives or mechanical sleeves to secure magnets against centrifugal forces, especially when using samarium cobalt magnets in high-heat environments.

Common Questions About What Magnet is Used in Permanent Magnet Motors

I get asked these questions constantly by engineers and hobbyists trying to figure out which rare earth motor magnets will actually hold up under pressure. Here is the lowdown on the most common concerns.

What’s the Strongest Magnet for a PM Motor?

The undisputed king of strength is the Sintered Neodymium Iron Boron (NdFeB) magnet. In terms of energy product ($BH_{max}$), nothing else comes close. These Ímãs permanentes NdFeB allow me to design motors that are incredibly small but pack a massive punch. If your goal is maximum torque in a tight space, this is your go-to material.

Why Use NdFeB Instead of Ferrite in EVs?

It comes down to weight and efficiency. While ferrite magnets for electric motors are dirt cheap, they have very low magnetic density. To get the same power as a small Neodymium rotor, a Ferrite version would be huge and heavy. For EV traction motor magnets, we need the high power-to-weight ratio that only high-grade neodymium magnets can provide to maximize battery range.

How Does Heat Affect My Magnets?

Heat is the primary enemy of magnetic flux. Every material has a Curie temperature for motor magnets, which is the point where they lose their magnetism permanently. Even before that, rising heat causes a temporary dip in performance. To prevent a total breakdown, I always monitor the magnetization and demagnetization curves of the specific magnet grade to ensure the motor stays within its “safe zone.”

Quick Comparison: Rare-Earth vs. Alternatives

| Característica | NdFeB (Neodímio) | SmCo (Samário Cobalto) | Ferrite (Cerâmico) |

|---|---|---|---|

| Força Magnética | Maior | Alto | Baixo |

| Resistência ao Calor | Moderado | Excelente | Alto |

| Custo | Alto | Muito Alto | Mais Baixa |

| Uso Comum | EVs, Robotics | Aeroespacial | Fans, Pumps |

Are There Rare-Earth Alternatives?

Yes, but there is always a trade-off. If you want to avoid rare earth motor magnets, you are looking at Ferrite or Alnico. These are great for cost-sensitive projects or very specific high-heat environments, but you will lose that compact “peak performance” factor. High-performance permanent magnet synchronous motor materials almost always rely on rare earths to meet modern efficiency standards.

Ensuring Consistent Magnetic Flux

Consistency starts with the manufacturing process. I look for magnet grades for PM motors that have tight tolerances on their magnetic properties. Using precision-ground arc segment magnets for rotors and ensuring a high-quality protective coating prevents the “flux drift” that happens when magnets start to corrode or age unevenly.

Deixe um Comentário